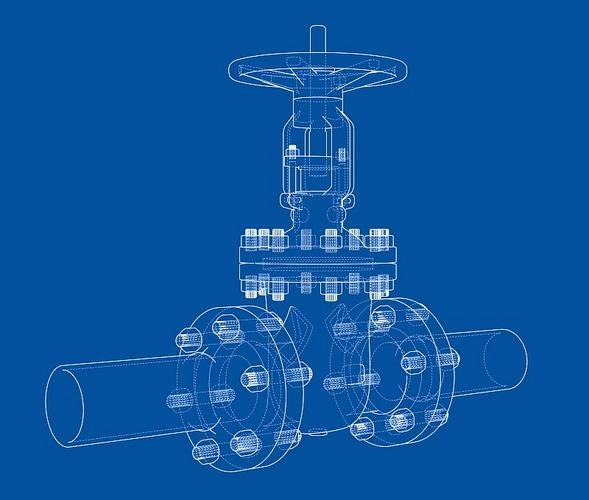

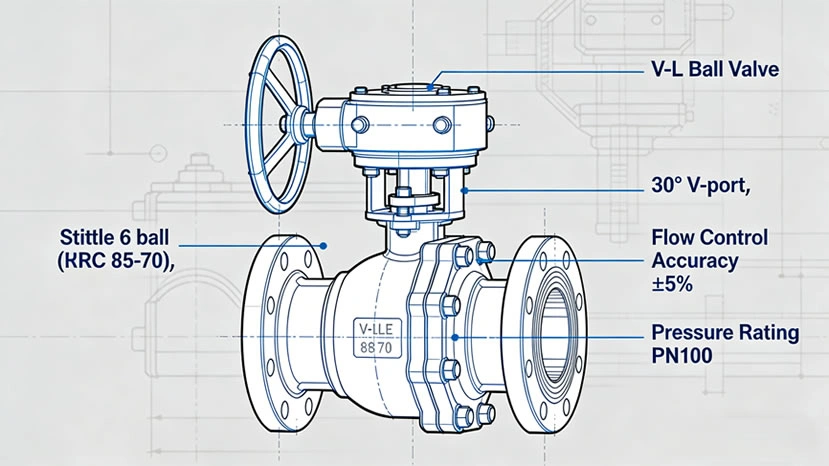

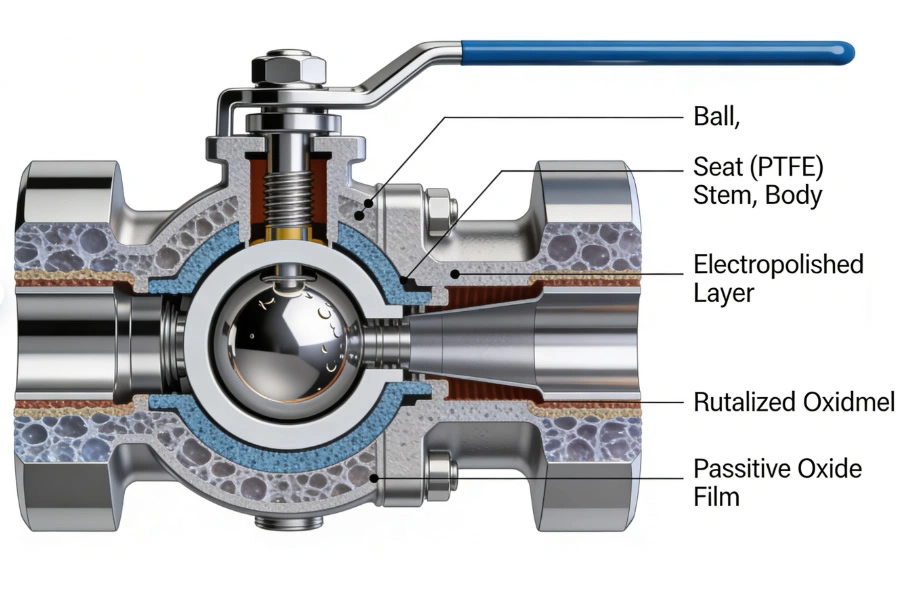

TIANYU's Industrial Flexible Wedge Full Bore Manual Pressure Steam Gate Valve combines flexible wedge design and pressure seal technology for high-temperature, high-pressure steam applications. Customizable in materials, coatings, and actuation, it meets ASME, API, and nuclear standards. With precision manufacturing, rigorous testing, and global certifications, it delivers reliable, long-lasting performance in power, petrochemical, and marine industries.