High-performance butterfly valves excel in extreme temperature environments, particularly suitable for high and low temperature conditions. Copper valves, with their superior thermal conductivity and corrosion resistance, are a crucial choice for various media. The hard-on-hard sealing design ensures tightness during high-intensity use, extending service life. These features make high-performance butterfly valves critical equipment in industries such as petroleum and chemicals, meeting complex process requirements.

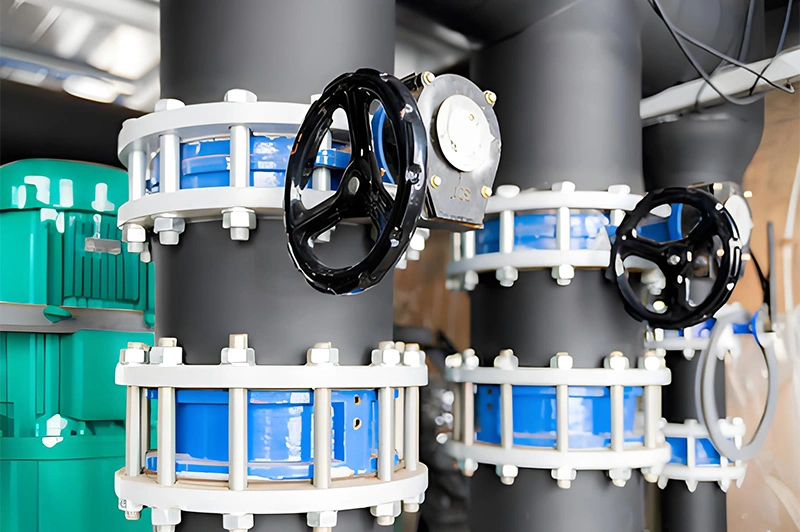

Concentric Butterfly Valve

As a distinguished concentric butterfly valve manufacturer in China, quality is our top priority.

Design Standards: API 609 Cat A, EN 593, BS 5155

Size Range: 2 – 72 Inch

Pressure Range: up to PN20

End Connections: Wafer, Lug, Flanged (FF, RF, RTJ)

Material Types: Iron, Carbon Steel, Stainless Steel, Duplex Steel, Al-BRZ, Alloy, Ti

Seat Type: NBR, Viton, EPDM, PTFE

Disc Fixing Type: With pin and without pin

Top Mounting: ISO 5211 top mounting is available

Operation Types: Lever, Gear, Pneumatic Actuator

Bosseal Valve advantages: 0 Leakage, low Torque, Long working life

Double Offset Butterfly Valve

With our state-of-the-art facilities and skilled workforce, we’re able to deliver top-quality double offset butterfly valves as one of the leading manufacturers in China.

Design Standards: API 609 Cat B

Size Range: 2 – 72 Inch

Pressure Range: Class 150-300 LB

End Connections: Wafer, Lug, Flanged (FF, RF, RTJ)

Material Types: Carbon Steel, Stainless Steel, Duplex Steel, Al-BRZ, Alloy, Ti

Seat Type: PTFE, RPTFE, PPL (for higher temperature), RPTFE+Metal (Fire Safe)

Top Mounting: ISO 5211 top mounting is available

Operation Types: Lever, Gear, Pneumatic Actuator

Bosseal Valve advantages: 0-Leakage, low Torque, Long working life, Low Emission, Bi-direction and fire safe

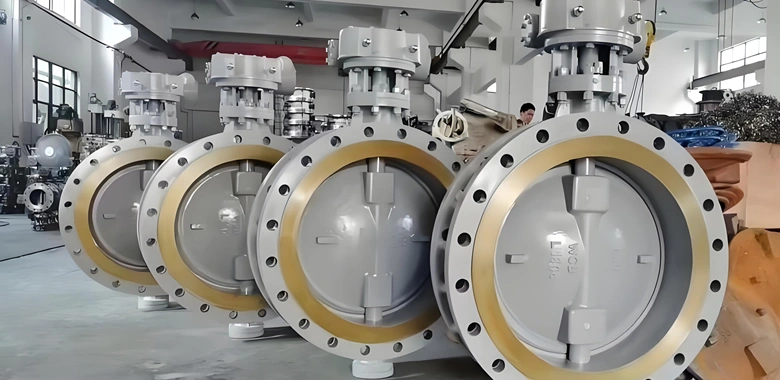

Triple Offset Butterfly Valve

Our company is widely recognized as one of the most reliable triple-offset butterfly valve manufacturers in China.

Design Standards: API 609 Cat B

Size Range: 2 – 72 Inch

Pressure Range: Class 150-2500 LB

End Connections: Wafer, Lug, Flanged (FF, RF, RTJ), BW

Material Types: Carbon Steel, Stainless Steel, Duplex Steel, Al-BRZ, Alloy, Ti

Seat Type: Metal with Hard facing

Disc Seat:

Solid metal seal ring (for bi-direction service)

or laminated graphite+SS seal ring

or laminated PTFE+SS seal ring (for service need cleanness like seawater)

Top Mounting: ISO 5211 top mounting is available

Operation Types: Lever, Gear, Pneumatic Actuator, Motor Actuator

Bosseal Valve advantages: 0 Leakage, low Torque, Long working life, Low Emission, Bi-direction and fire safe