The sealing element is vital for valves, preventing media leakage when closed. Made of durable, corrosion-resistant materials, it withstands pressure, temperature, and corrosion. Its repeated friction during operation makes material choice and manufacturing quality crucial for sealing performance and valve lifespan, regardless of valve type.

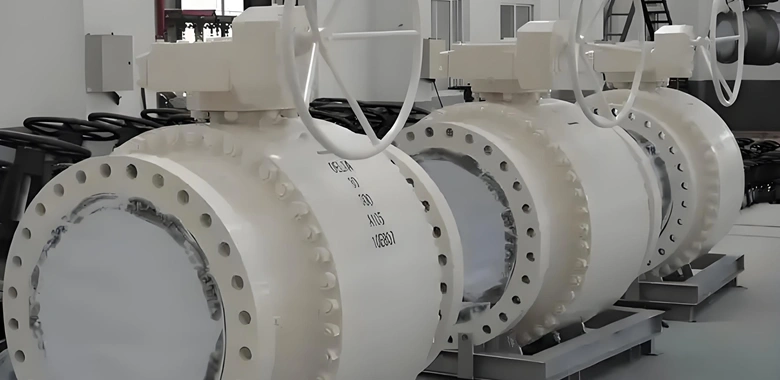

TIANYU DN100 PN16 high-temp metal seal ball valve: stainless steel, flange connection, floating/trunnion options. Handles -196~550℃, 1.6-10.0MPa, media like oil, steam, LNG. Ideal for oil, gas, power sectors. Reliable, corrosion-resistant, with versatile drives. Suits diverse industrial needs.