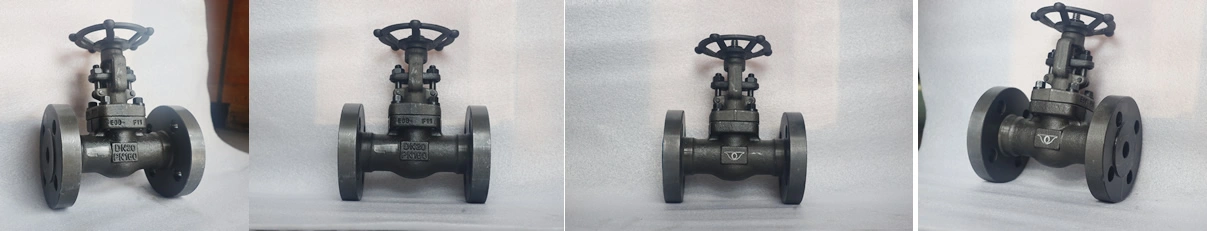

TIANYU DN20 PN160 F11 Alloy Steel Gate Valve with Raised Face Flange Connection and Handwheel Operation

I. Product Overview

TIANYU DN20 PN160 gate valve is a high-pressure flow control solution engineered for extreme industrial environments requiring robust performance and temperature resistance. Constructed with an F11 alloy steel body (1.25Cr-0.5Mo) and featuring a raised face flange connection with handwheel operation, it delivers reliable shut-off capabilities for high-pressure media such as steam, hot oil, and gas. Designed to operate at 16.0MPa (PN160) and -29℃~593℃, this valve complies with ASME B16.34 and API 600 standards, making it ideal for power generation, oil & gas, and chemical processing systems where high pressure, high temperature, and corrosion resistance are critical.

II. Key Attribute Specifications

|

Category

|

Details

|

|

Size

|

DN20 (3/4”), suitable for small-diameter high-pressure pipelines requiring precise flow control.

|

|

Pressure Rating

|

PN160 (16.0MPa), designed for high-pressure systems such as power plant steam lines and offshore drilling manifolds.

|

|

Body Material

|

F11 alloy steel (ASTM A182 F11), a 1.25Cr-0.5Mo low-alloy steel with excellent high-temperature strength (tensile strength 485-655MPa) and creep resistance.

|

|

Trim Components

|

– Gate and Seat: F22 alloy steel (2.25Cr-1Mo) with hardfacing (stellite) for wear resistance.- Stem: F11 alloy steel, nitride-treated for corrosion and scratch resistance.

|

|

Connection

|

Raised face flange (ASME B16.5), ensuring tight sealing with companion flanges via spiral-wound gaskets, compatible with high-pressure pipeline systems.

|

|

Actuation

|

Handwheel operation with a worm gear reducer, providing mechanical advantage for easy operation under high pressure.

|

|

Temperature Range

|

-29℃~593℃, suitable for high-temperature media like superheated steam and hot oil.

|

|

Design Standards

|

ASME B16.34 (valve dimensions), API 600 (gate valves for petroleum and natural gas industries), ASTM A182 (F11 material specifications).

|