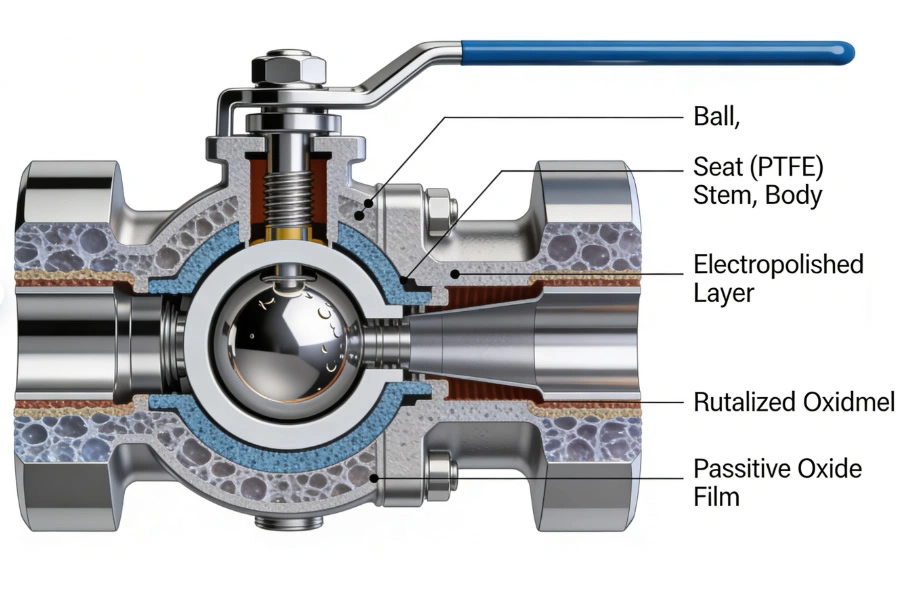

TIANYU’s custom high-purity electropolished ball valves (Ra ≤ 0.4 μm) deliver uncompromising purity and performance for pharmaceutical, semiconductor, and chemical applications. Engineered with 316L/316Ti/Hastelloy materials and PTFE/PEEK/metal seals, they meet FDA, USP, and SEMI standards, with metal ion leaching ≤ 0.1 ppb and particle counts ≤ 10 particles/mL. Full-port designs cut energy use by 40%, while CIP/SIP compatibility reduces cleaning time by 20%. Backed by ISO 9001 certification, 100% Ra testing, and 24/7 global support, TIANYU’s valves ensure regulatory compliance, process efficiency, and product quality for critical fluid systems.