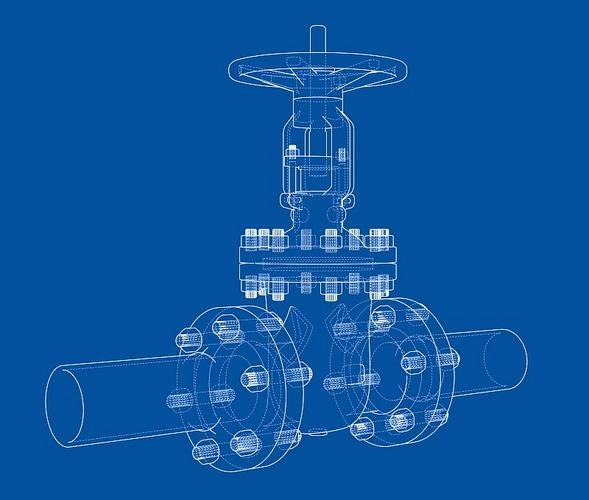

Metal Seal ball valve for severe services: high temperature, hight pressure and abrasive service; metal Seal floating and trunnion mounted ball valves with zero leakage, meeting En 12266-1 rate A.

We have side entry and top entry metal Seal ball valves. Metal Seal ball valves are ideal for isolation purpose.

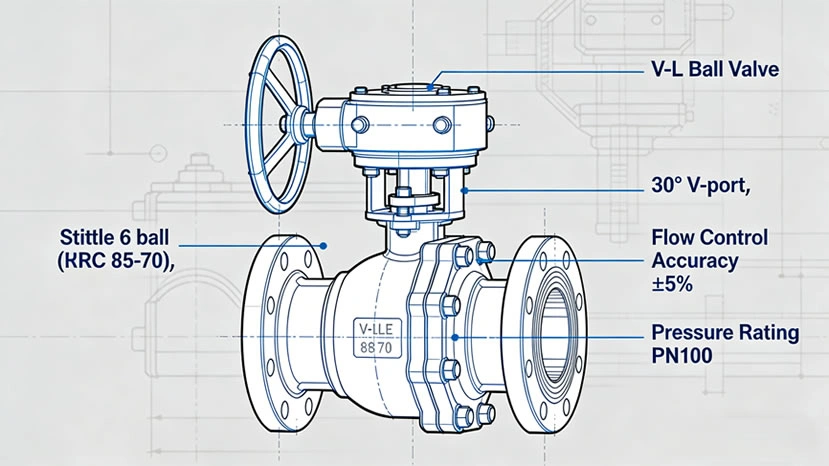

Relia Metal Seal ball valves have advantages, such as excellent corrosion & wear resistance, tight shut-off, smooth control, low torque, wide temperature & pressure range, as well as stability under pressure.

Relia Valve is a metal Seal ball valve manufacturer & supplier in China, with API 6D, API 607 and CE Certificate, providing best price metal Seal ball valves.

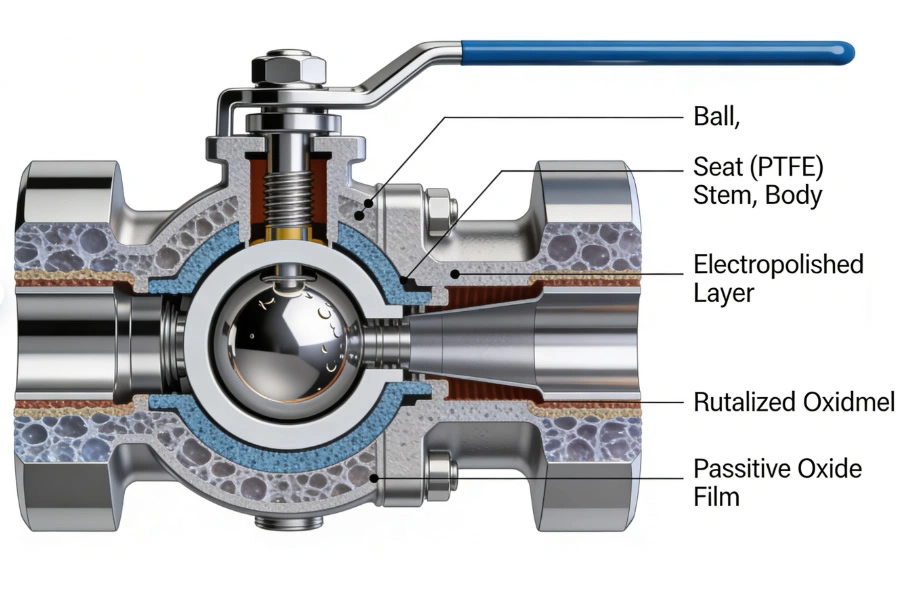

The Seal ring and ball are precisely machined and lapped to match ball, creating a positive seal for bubble-tight performance. Metal Seal ball valve provides long service life with outstanding fugitive emissions performance and low operating torques in even the toughest applications.

Industries application

As one of the top metal Seal ball valve manufacturers, Relia valve has experience in serving the Oil & Gas, Petroleum, Petrochemical, Chemical, Power Generation, Pulp & Paper, and Mining industries.

Petrochemical

The P-series metal Seal ball valves handle applications in corrosive, abrasive, slurry, extreme pressure, catalyst, chemical, and petrochemical applications.

Mining for Metals and Minerals

M-series metal Seal ball valves handle applications in mining, slurry transport, autoclave (HPAL), and heavy slurry.

Power generation

PG-Series metal Seal ball valves handle applications in power generation. They feature in-line repairable, automated relief valve systems, solids, ash-handling blocks, and isolation valves.

Refining

The R-Series metal Seal ball valves handle specific applications from isolation to welded end valves, catalyst handling, RF-Series for high alloy customized valves, and D-Series for double block and bleed designs.