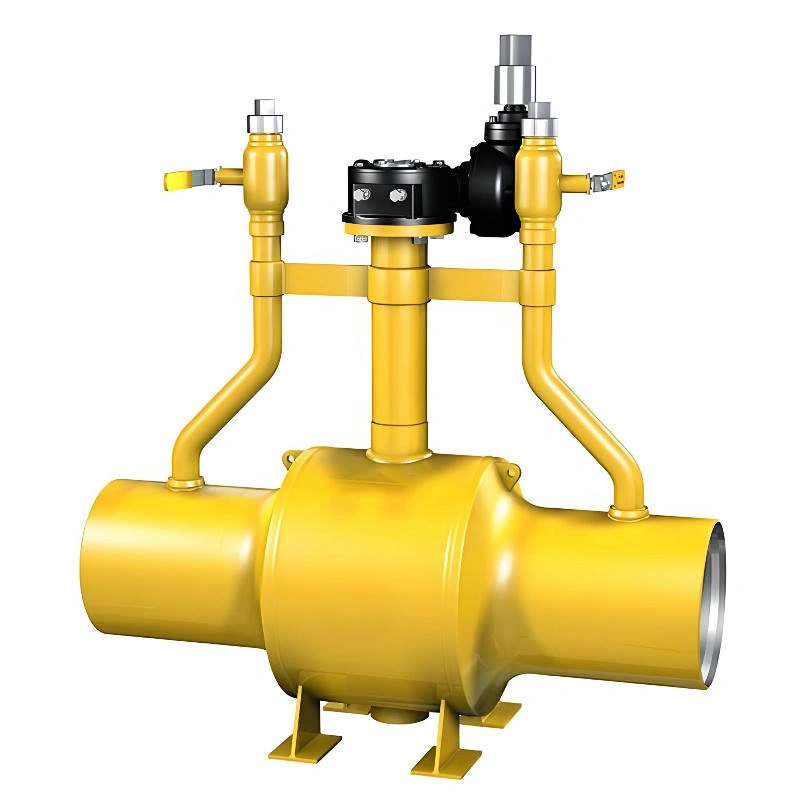

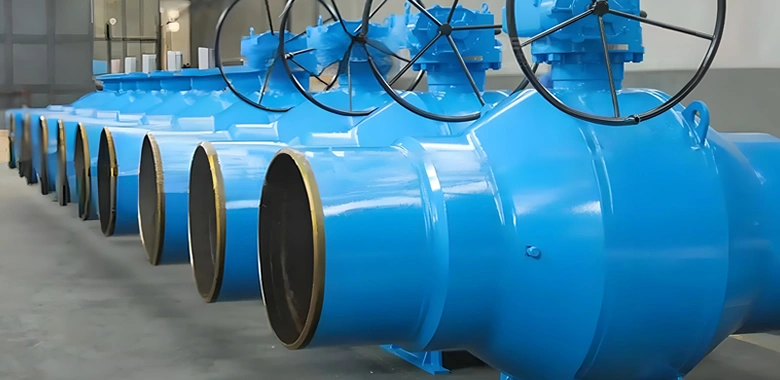

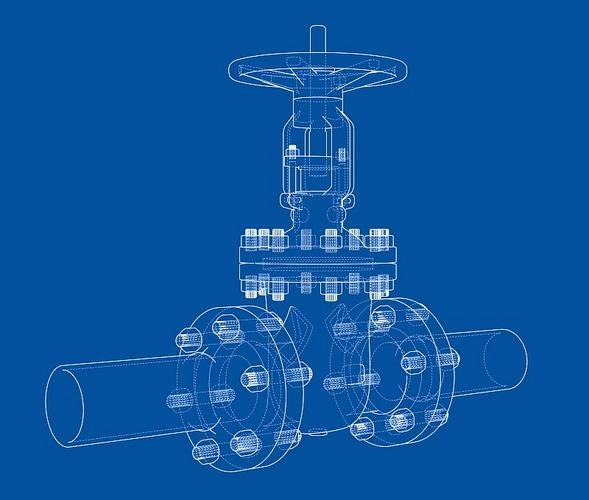

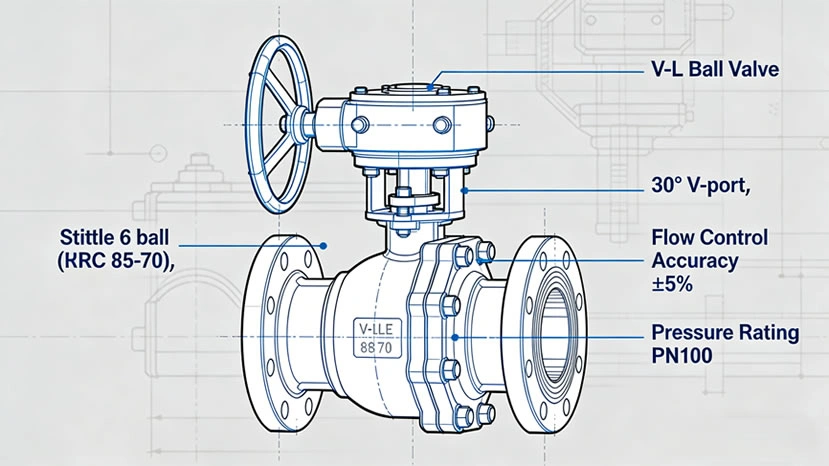

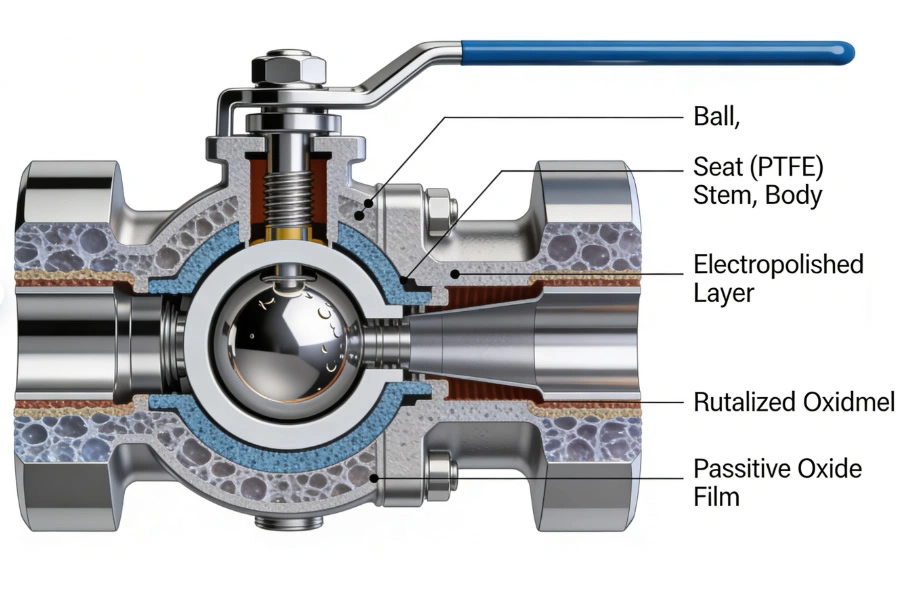

TIANYU Class 150 DN300-DN1000 WCB full welded trunnion-mounted ball valve: worm gear operated, soft-sealed, -29℃~300℃, ANSI Class VI leakage. Ideal for municipal, oil/gas, chemical, power sectors needing reliable large-diameter flow control. API 6D compliant, cost-effective, low maintenance, with superior leak-tightness.Customize with 304/316 stainless steel body, RPTFE/PEEK seals, Class 300/600 pressure rating, fire-safe design (API 607), NACE MR0175 for sour service, or electric/pneumatic actuator. Tailor to your media, pressure, temperature, and installation requirements.