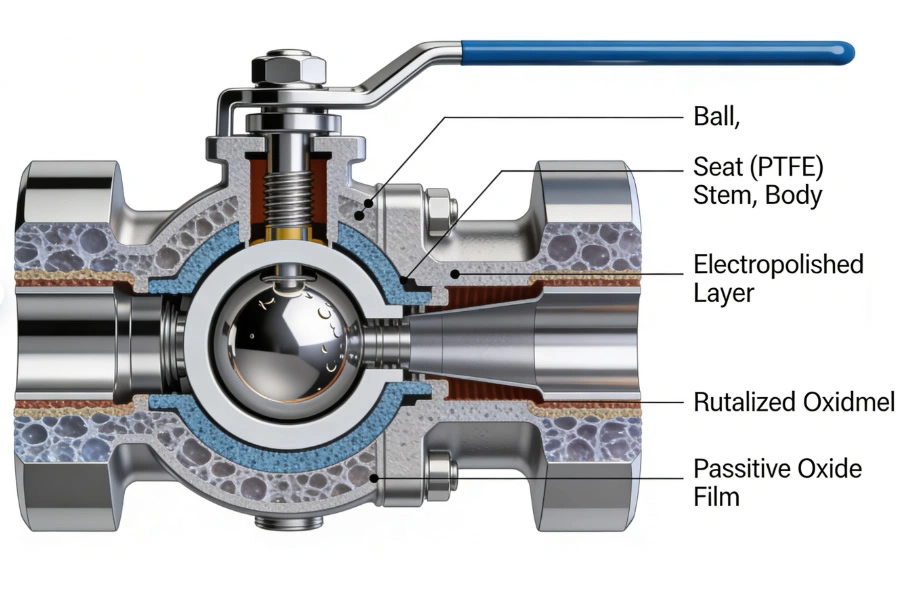

The sealing element is vital for valves, preventing media leakage when closed. Made of durable, corrosion-resistant materials, it withstands pressure, temperature, and corrosion. Its repeated friction during operation makes material choice and manufacturing quality crucial for sealing performance and valve lifespan, regardless of valve type.

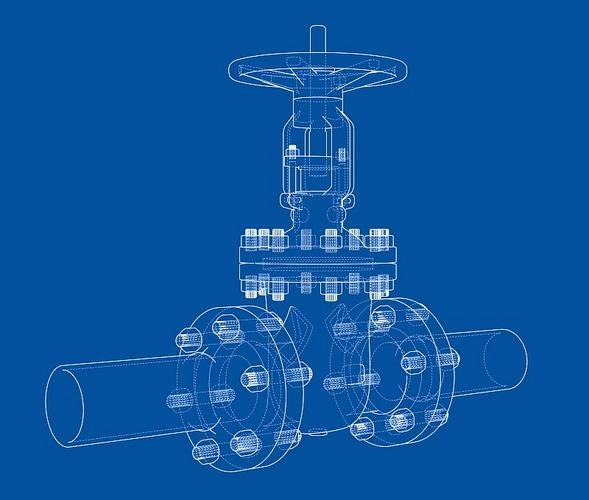

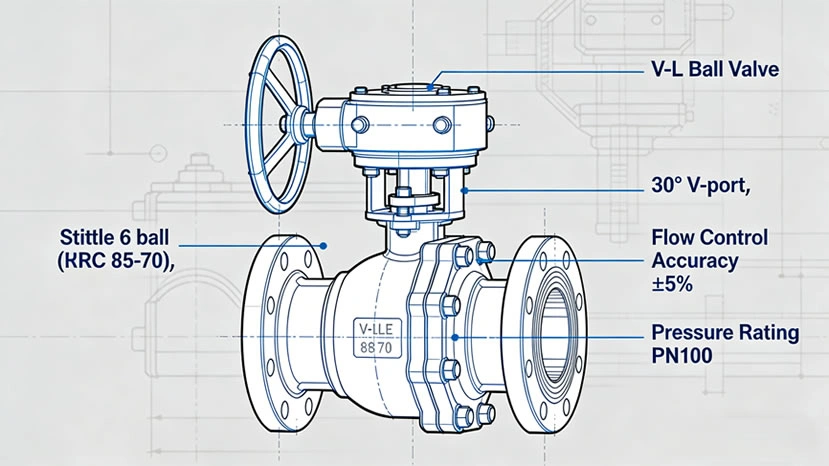

DN40 150LB A105 Carbon Steel Flanged Forged Steel Gate Valve DN40 150LB gate valve: A105 carbon steel, RF flange, handwheel. Reliable for water, oil, gas in medium-pressure systems. Cost-effective, easy to maintain.Customize with: 316 stainless steel trim for corrosion resistance, extended bonnet for cryogenic service, or electric actuators for automation. Tailored to your media, pressure, and control needs.