I. Testing: The Last Line of Defense for Industrial Safety

(1) Accident Warnings: Catastrophes from Millimeter-Level Errors

- 2022 North American Refinery Explosion: A gate valve internal leakage caused by missing API 598 seal testing triggered an oil-gas explosion, resulting in $240 million in direct economic losses.

- LNG Terminal Liquid Ammonia Leakage: A cryogenic valve failed the -196°C deep cooling impact test, causing the valve body to crack and injuring 3 people, with production shutdown losses exceeding 50 million yuan.

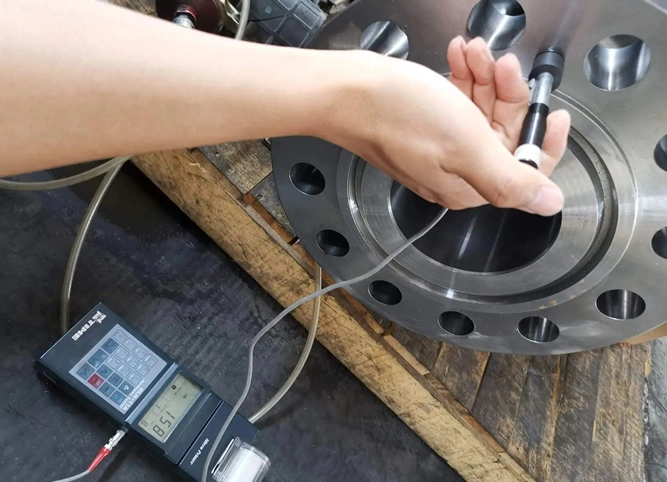

UT Inspection

(2) Industry Iron Rules: Safety Red Lines Behind Data

- Seal Failure Proportion: 68% of valve failures originate from sealing defects (ISO 5208 statistics).

- Stringent EU Standards: Oil-gas valves must have a leakage rate ≤0.1ppm (ISO 5208 Class A), equivalent to a matchstick not flickering 3 meters away.

- Chinese Mandatory Regulations: TSG D7005 requires 100% shell strength testing for pressure pipeline valves, with zero missed inspection rate.

II. Seven Core Testing Projects: From Micron-Level to Extreme Conditions

(1) Seal Integrity Testing: The “Cardiopulmonary Function” Test for Valves

| Standard | Test Pressure | Leakage Limit | Application Scenarios | Testing Equipment | Accuracy |

|---|---|---|---|---|---|

| API 598 | 1.5×PN (shell) | Visual bubble-free (bubble-tight seal) | General oil & gas valves | Hydraulic test bench | Pressure control ±0.5%FS |

| ISO 5208 | 1.1×PN (seal) | ≤0.1ml/min·mm seal circumference (Class A) | Chemical & pharmaceutical valves | Pneumatic leakage detector | Leakage resolution 1×10⁻⁹mbar·L/s |

| API 607 | After 30-min fire test | Leakage rate ≤0.5% (gas medium) | Fire-safe soft-sealed valves | Fire resistance furnace + mass spectrometer leak detector | Temperature control ±2℃ |

Technological Evolution:

- Helium Mass Spectrometry Leak Detection: Captures helium molecules via vacuum systems, detecting 0.1μm-level leak holes, suitable for high-purity gas valves in semiconductor industries.

- AI Visual Inspection: Equipped with 12K resolution cameras, automatically identifying 0.05mm-level liquid leakage traces with <0.3% false positive rate.

(2) Pressure Strength Testing: “Compression Test” for Ultimate Pressure Resistance

- Shell Burst Test: As per ASME B16.34, 1.5× nominal pressure is maintained for 30 minutes, monitored in real-time by electronic pressure recorders with pressure fluctuation ≤0.1%FS.

- High-Pressure Fatigue Test: Valves above Class 900 must pass 1,000 pressure cycles (0-1.3×PN), supported by servo hydraulic systems with displacement control accuracy ±0.02mm.

- Safety Valve Setting: ASME BPVC Section VIII specifies setting pressure error ≤±3%, using intelligent pressure calibration benches with response time <200ms.

(3) Material & Structural Testing: Full-Dimensional Scanning from Atoms to Macroscale

| Testing Technology | Testing Object | Defect Type | Accuracy Index | Equipment Configuration |

|---|---|---|---|---|

| Direct Reading Spectrometry | Chemical composition | Element deviation | 316 stainless steel Mo content ±0.05% | Desktop spectrometer (5s excitation) |

| Magnetic Particle Testing (MT) | Surface defects | Cracks, folds | 0.1mm-level shallow defects | Fluorescent magnetic particle tester (magnetic field ≥2000Oe) |

| Ultrasonic Testing (UT) | Internal defects | Slag inclusions, shrinkage | Φ1mm flat-bottom hole equivalent reflection | Phased array ultrasonic instrument (16-element probe) |

| Metallographic Analysis | Microstructure | Grain size, carbide distribution | Grain size rating ≥ Grade 6 (ASTM E112) | Inverted metallographic microscope (1000× magnification) |

III. Special Valves: Differentiated Testing Solutions

(1) Ball Valves: “Dual Tests” for Bi-Directional Sealing

- Floating Ball Valves:

- Seal specific pressure test: Using high-precision pressure sensors (accuracy 0.2%FS), ensuring seal face pressure ≥6MPa under bi-directional pressure.

- Fire structure verification: API 607 certification requires passing 800℃ fire test, with metal emergency seals maintaining leakage rate ≤0.5% within 30 minutes.

- Trunnion-Mounted Ball Valves:

- Stem torque test: Servo motor drive device controls torque fluctuation within ±15% to avoid jamming (ISO 5208 Annex C).

(2) Butterfly Valves: Balancing Rubber Elasticity and Metal Thermal Expansion

- Centerline Soft-Sealed Butterfly Valves:

- Rubber compression testing: Laser displacement sensors measure seat compression (15%-20%), and 70℃ aging chamber tests for 168 hours with hardness change ≤10HA (Shore hardness).

- Triple Eccentric Metal-Sealed Butterfly Valves:

- High-temperature cycle test: 200-500℃ alternating temperature chamber (heating rate 5℃/min), leakage rate ≤0.1% after 100 cycles (ISO 15848-1).

(3) Safety Valves: Decisecond-Level Relief Precision

- Discharge Capacity Verification: Discharge coefficient ≥0.9 measured on steam test benches, equipped with orifice flowmeters (accuracy ±0.5%) and high-speed cameras (1000fps) to capture disc opening status.

- Opening/Closing Pressure Difference Control: EN ISO 4126 requires ≤7% of setting pressure, achieved via intelligent measurement and control systems for 0.1% 级 pressure fine-tuning.

IV. Intelligent Testing Equipment: Reconstructing Industrial Testing Paradigms

(1) Fully Automatic Testing Platform: Micron-Level Precision Control

- 6-Axis Robotic Arm Clamping System: Adaptable to DN15-DN2000 valves with positioning accuracy ±0.1mm, compatible with 8 connection types including flanged and butt-welded.

- AI Visual Leakage Positioning: 12K resolution linear array cameras scan sealing surfaces, combined with deep learning algorithms, achieving 99.7% recognition accuracy for 0.05mm-level droplets.

- Dynamic Data Acquisition: Electronic pressure recorders collect data at 100Hz, generating curves compliant with API 598, with traceable data error ≤0.01%.

(2) Predictive Maintenance System: From Passive Testing to Active Prevention

- IoT Sensor Matrix: Torque, temperature, and vibration sensors installed on valves upload real-time data to cloud platforms, with Abnormal fluctuation warning response time <5s.

- Digital Twin Model: Simulates extreme conditions of 850℃ and 42MPa via ANSYS, predicting seal face wear ≤5μm and shortening design cycles by 40%.

V. Extreme Conditions: Testing Solutions Challenging Limits

(1) Acidic Environment (H₂S): “Race Against Time” for Corrosion Resistance

- NACE MR0175 Mandatory Requirements:

- Valve body hardness testing: Rockwell hardness tester (HRC scale) measures ≤22HRC to avoid sulfide stress cracking.

- Accelerated corrosion test: 2000ppm H₂S environmental chamber (25℃±1℃), with crack propagation rate ≤0.01mm/day after 96 hours.

(2) Ultra-Low Temperature Scenarios (-196℃): Double Limits of Toughness and Sealing

- Cryogenic Impact Test: After 2-hour liquid nitrogen immersion, Charpy impact test (V-notch) shows impact energy ≥27J (ASTM A352 LCC).

- Anti-Icing Design Verification: Stem heating jacket power density 3W/cm², ≤5μm residual deformation on sealing surfaces after 500 cycles in -196℃ environment (measured by laser micrometer).

VI. Global Compliance Certification: Passports Crossing Technical Barriers

| Certification System | Core Requirements | Testing Focus | Application Fields |

|---|---|---|---|

| API 6D | 1 million cycle life + temperature cycle test | Desert/marine environment simulation | Oil-gas long-distance pipeline valves |

| CE-PED 2014/68/EU | Module B+C2 audit + FMEA failure analysis | Risk level Cat.III assessment | EU pressure equipment market |

| ASME NPT | Material heat number traceability + 100% radiography | Nuclear-grade water compatibility test | Nuclear main steam valves |

| TSG D7005 | Full-size inspection + stress analysis report | Seismic resistance verification under earthquake conditions | Key valves for Chinese pressure pipelines |

VII. Failure Case Decoding: Extracting Solutions from Accidents

(1) Gate Valve Jamming: The Fatal Impact of Surface Precision

- Root Cause Analysis: Stem thread roughness Ra>1.6μm, with sediment particles embedding and increasing friction coefficient from 0.15 to 0.32.

- Solutions:

- Electrolytic polishing reduces Ra to ≤0.8μm, decreasing surface energy by 40%.

- Double-lip dust-proof seals added (complying with ISO 5208 Annex D), with dust interception efficiency ≥99%.

(2) Ball Valve High-Temperature Internal Leakage: Breaking through Seal Material Limits

- Technical Bottleneck: Traditional PTFE seats have creep rate >5% at 260℃, reducing seal specific pressure from 6MPa to 4MPa.

- Innovative Solutions:

- PEEK+30% carbon fiber composite material, with temperature resistance increased to 316℃ and creep rate ≤1.2%.

- Optimized seal face cone angle to 20°, maintaining specific pressure ≥8MPa (API 608 revised edition).

VIII. Cutting-Edge Technologies: Redefining the Future of Testing

(1) Digital Twin: Pre-Verification in the Virtual World

- Simulation Advantages: ANSYS Workbench simulates high-temperature and high-pressure coupled conditions, identifying seal face stress concentration points in advance and reducing physical tests by 50%.

- Cost-Effectiveness: The design cycle for a nuclear valve was shortened from 18 to 10 months, with material waste reduced by 47%.

(2) Green Testing: Sustainable Industrial Practices

- Infrared Thermal Imaging Leak Detection: Utilizes the throttling temperature drop effect of leakage points (temperature difference ≥3℃), eliminating medium charging and shortening testing time by 60%.

- Biodegradable Media: FDA-certified glycerol aqueous solution (30% concentration) replaces mineral oil for food-pharmaceutical valves, reducing cleaning water consumption by 80%.

(3) Blockchain Traceability: Data as Trust

- Technical Implementation: Testing data is uploaded to the blockchain in real-time, with each report generating a unique hash value. Scanning the code reveals the full process record of the valve from smelting to installation.

- Industry Value: A petrochemical project reduced customs clearance time from 72 to 8 hours and improved compliance audit efficiency by 90% with blockchain reports.

Conclusion: Guarding Industrial Pulse with Testing Precision

From the explosion warning in North American refineries to the ppm-level leakage limits in the EU, industrial valve testing has always been the balance point between safety and efficiency. When 6-axis robotic arms precisely clamp valves, when AI vision captures micron-level leaks, and when digital twins simulate extreme conditions in the virtual world, testing technology is evolving from “post-event verification” to “pre-event prevention”.

In Tianyu Valves’ -269℃ liquid helium laboratory, testing engineers use 0.01% pressure control accuracy and 5μm deformation measurement capabilities to lay the safety foundation for LNG ship valves. These seemingly cold technical parameters are actually warm lines of defense for industrial safety—every precise test is a solemn commitment to life and property.