A comprehensive guide to understanding the symbols of different types of valves

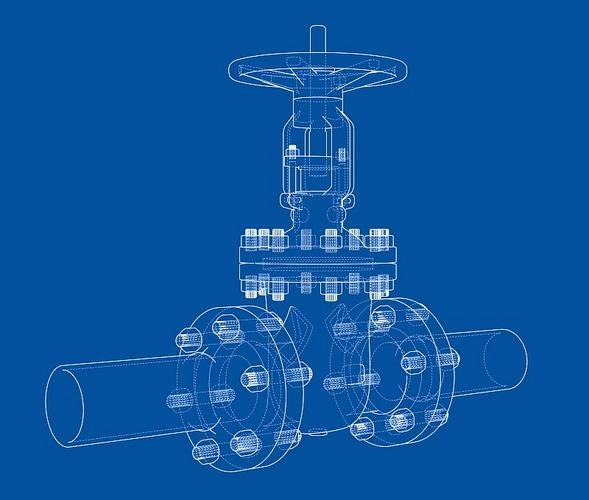

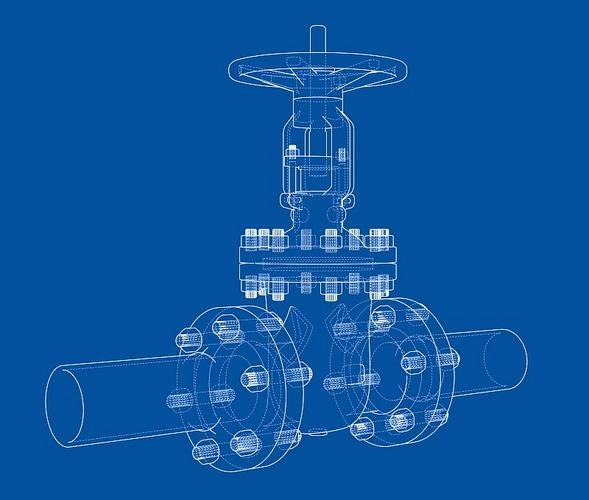

I. Introduction In the global industrial sector, valves are critical components for controlling fluid flow, pressure, and direction in piping systems across oil & gas,

What’s The Difference Between Ball Valve And Butterfly Valve?

To provide a more comprehensive comparison between industrial ball valves and butterfly valves, let’s delve deeper into their characteristics, including material choices, ease of maintenance,To provide a more comprehensive comparison between industrial ball valves and butterfly valves, let’s delve deeper into their characteristics, including material choices, ease of maintenance,To provide a more comprehensive comparison between industrial ball valves and butterfly valves, let’s delve deeper into their characteristics, including material choices, ease of maintenance,

Tianyu Valve Co., Ltd. specializes in research on industrial valve technology, providing in-depth analysis of cutting-edge industrial valve technologies. From high-pressure resistant designs to intelligent controls, each technical article stays closely attuned to industry trends, leveraging precise data and professional analysis to empower clients to optimize processes, enhance efficiency, and spearhead new trends in valve technology.

In the realm of Industry News, we bring you the latest advancements in high-performance valves. These valves, renowned for their exceptional durability, precision control, and adaptability to diverse industrial applications, are revolutionizing fluid management in sectors ranging from petrochemicals to power generation, food processing to environmental protection. Our focus on the latest trends and innovations in valve technology ensures that you stay ahead of the curve, harnessing the power of cutting-edge solutions to optimize your processes, enhance safety, and drive sustainable growth.

I. Introduction In the global industrial sector, valves are critical components for controlling fluid flow, pressure, and direction in piping systems across oil & gas,

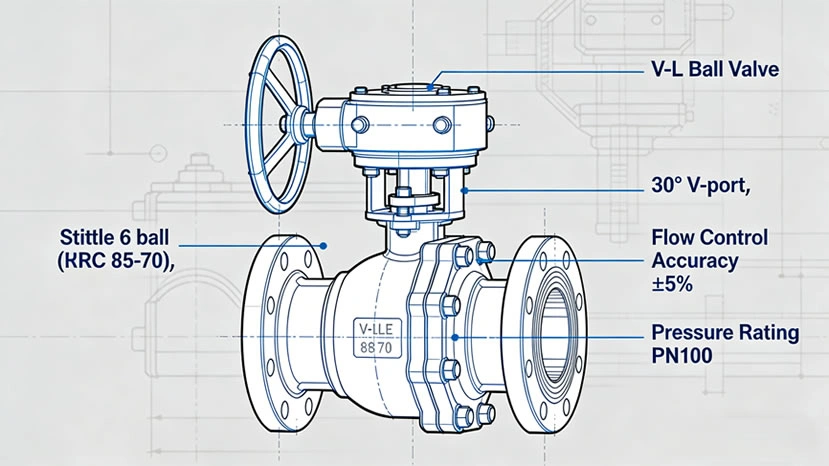

I. Introduction: The Critical Role of V-Port Ball Valves in Mining Slurry Operations Mining operations—from copper and iron ore extraction to coal and mineral processing—rely

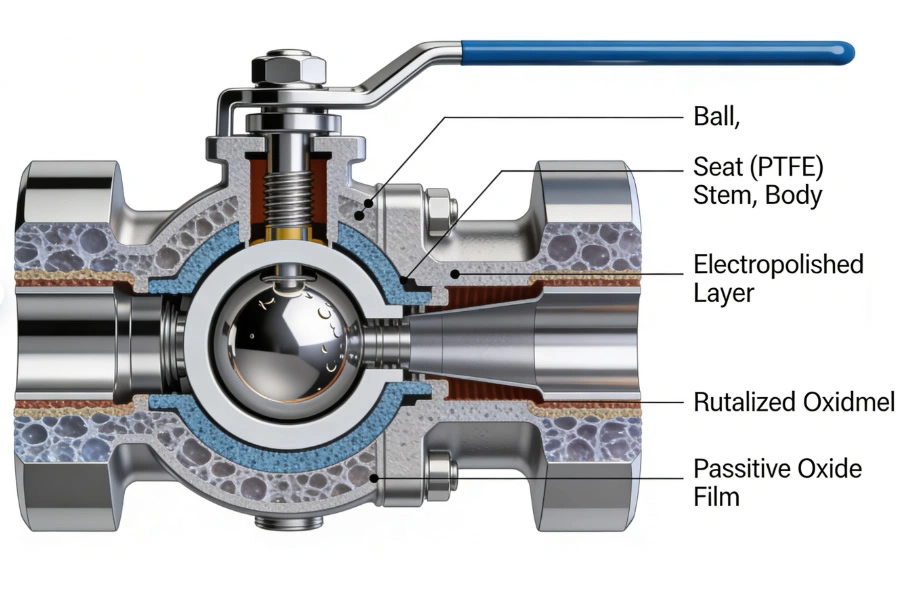

TIANYU’s custom high-purity electropolished ball valves (Ra ≤ 0.4 μm) deliver uncompromising purity and performance for pharmaceutical, semiconductor, and chemical applications. Engineered with 316L/316Ti/Hastelloy materials and PTFE/PEEK/metal seals, they meet FDA, USP, and SEMI standards, with metal ion leaching ≤ 0.1 ppb and particle counts ≤ 10 particles/mL. Full-port designs cut energy use by 40%, while CIP/SIP compatibility reduces cleaning time by 20%. Backed by ISO 9001 certification, 100% Ra testing, and 24/7 global support, TIANYU’s valves ensure regulatory compliance, process efficiency, and product quality for critical fluid systems.

As the final notes of 2025 fade and the dawn of 2026 breaks, the industrial sector reflects on a year of resilience, innovation, and collaborative

I. Introduction: The Critical Role of Actuated Valves in Modern Industrial Processes In the landscape of industrial process control, valves serve as the “gatekeepers” of

I. Introduction Butterfly valves have emerged as cornerstone components in industrial fluid control systems, celebrated for their compact footprint, lightweight construction, and exceptional flow regulation

I. Introduction: The Critical Role of Valve Selection in Industrial Systems Valves serve as the “control nodes” of industrial fluid systems, regulating the flow of

TIANYU’s IoT smart ball valves (DN15–DN600) deliver 10-second leak detection (0.05 mm accuracy) via custom sensor arrays and ML algorithms. 316L/duplex bodies and PTFE/PEEK seats ensure durability (100,000+ cycles), while LoRaWAN/5G modules enable 99.9% data transmission. Compliant with API 6D/NSF 61, they cut TCO by 40% vs. traditional valves. 5-year warranties, 24/7 support, and tailored software (SCADA integration) make them ideal for municipal, chemical, and oil/gas use.

Large-diameter water Butterfly Valves mains (DN>300) form the backbone of municipal water supply, wastewater treatment, and industrial process systems, transporting 50–90% of potable water and

Tianyu Professional China Valve Manufacturers and Supplier Conforming ISO APl CE certification standards

Send us a message if you have any questions or request a quote. Our experts will give you a reply within 24 hours and help you select the right valve you want.

Founded in 2009, Wenzhou Tianyu Valve Technology Co., Ltd. is a professional valve enterprise integrating design, development, production, and sales services, located in the hometown of Chinese valves – Oubei Town, Wenzhou.

Copyright@2026 Tianyu Valve CO.,LTD. Sitemap All rights reserved.