Ball valves are ubiquitous in industrial fluid handling—from oil and gas pipelines to chemical processing—due to their fast 90° actuation, tight sealing, and durability. However, selecting between full port (FP) and reduced port (RP) designs is critical: it directly impacts flow efficiency, energy consumption, and long-term operational costs.

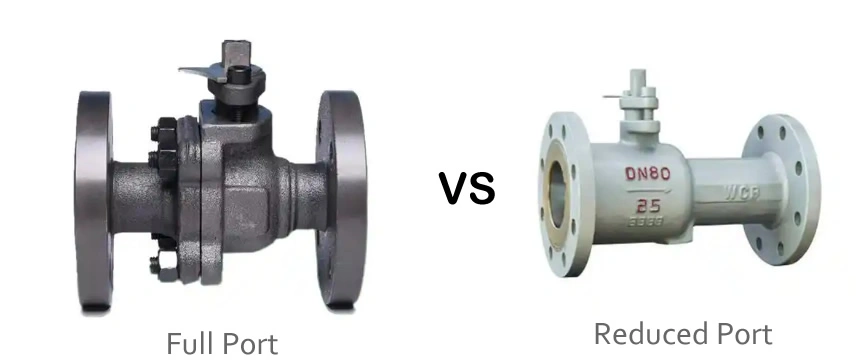

Full port valves feature a ball bore equal to the pipeline’s inner diameter (ID), minimizing flow restriction. Reduced port valves have a smaller ball bore (typically 25–50% less than pipeline ID), prioritizing space and cost savings over maximum flow. This article compares their design, flow efficiency metrics (KV, pressure loss), real-world performance data, application suitability, and TIANYU’s tailored solutions—helping engineers make data-driven selections for specific industrial needs.

I. Core Design Differences: Full Port vs. Reduced Port

The fundamental distinction between FP and RP ball valves lies in their internal geometry, which dictates flow behavior. Below is a detailed breakdown of key design elements and how they differ.

A. Ball Bore and Flow Channel Geometry

- Full Port (FP) Ball Valves:

-

- The ball’s internal bore matches the pipeline’s ID (e.g., DN100 pipeline → 100 mm ball bore). This creates an unobstructed flow path when the valve is fully open.

-

- Flow channel: Smooth, straight, and concentric with the pipeline—no sudden changes in cross-sectional area that cause turbulence.

-

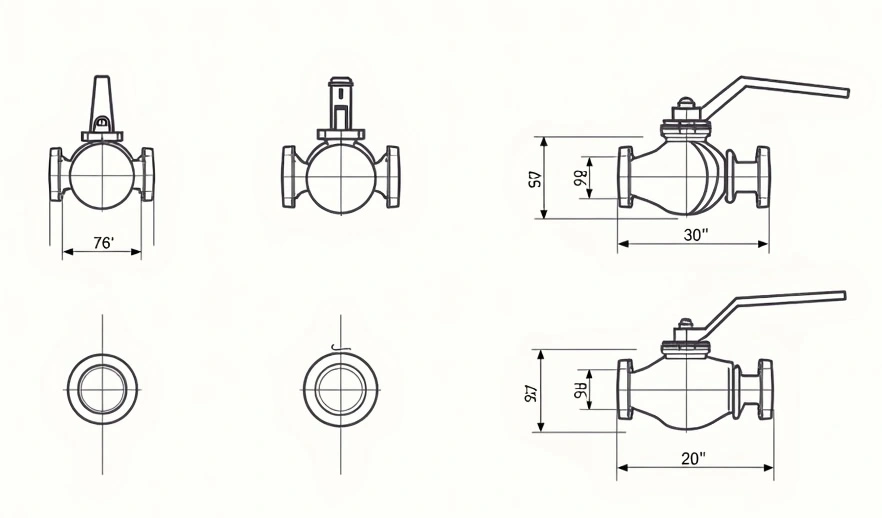

- Typical design: Larger ball and valve body (to accommodate the full-bore ball); requires more installation space (e.g., DN150 FP valve has a body length 20–30% longer than an RP equivalent).

- Reduced Port (RP) Ball Valves:

-

- The ball’s bore is 25–50% smaller than the pipeline ID (e.g., DN100 pipeline → 75 mm or 50 mm ball bore; industry terms like “3/4 port” or “1/2 port” describe this reduction).

-

- Flow channel: Features a sudden contraction at the ball and expansion downstream—creates turbulence and increases flow resistance.

-

- Typical design: Compact body and smaller ball (e.g., DN150 RP valve weighs 30–40% less than an FP equivalent); ideal for space-constrained areas (e.g., skid-mounted equipment).

B. Material and Structural Considerations

- Full Port:

-

- Requires more raw material (larger ball/body), so material selection balances strength and cost. Common materials: A105N carbon steel (low-pressure, ≤PN16), F316L stainless steel (corrosive media), or duplex S31803 (high-pressure, ≤PN42).

-

- Stem design: Thicker stem (to support the larger ball); often uses anti-blowout structures (per API 6D) for high-pressure service.

- Reduced Port:

-

- Less material usage reduces cost (15–25% lower than FP for the same DN/PN). Materials overlap with FP but prioritize lightweight options (e.g., cast aluminum for low-pressure air service).

-

- Stem design: Smaller stem diameter (lower torque requirements); suitable for manual or small electric actuators.

C. Actuation Requirements

- Full Port:

-

- Larger ball mass increases operating torque (e.g., DN200 PN16 FP valve requires 250 N·m torque vs. 180 N·m for RP). Typically needs larger actuators (e.g., 1.5 kW electric vs. 1.0 kW for RP).

-

- Actuation speed: Slightly slower (5–10 seconds full open/close) due to higher inertia, but still within industrial standards.

- Reduced Port:

-

- Lower torque (30–40% less than FP) enables smaller, more cost-effective actuators. Manual operation is feasible for DN≤100 (FP DN100 often requires gear operators).

-

- Actuation speed: Faster (3–7 seconds full open/close) due to lighter moving parts—critical for emergency shutdown (ESD) applications.

II. Flow Efficiency Metrics: Quantifying Performance Differences

Flow efficiency is measured by two key metrics: flow coefficient (KV) and pressure loss (ΔP). These values directly impact pump energy consumption and system throughput—making them the primary basis for selecting FP vs. RP.

A. Flow Coefficient (KV)

KV represents the volume of water (m³/h) that flows through a valve at a pressure drop of 1 bar (0.1 MPa) and 20°C. Higher KV means better flow efficiency.

Imported reduced-neck ball valve and imported full-bore ball valve

Comparative KV Data (Same DN/PN)

|

Nominal Diameter (DN)

|

Full Port KV Value

|

Reduced Port KV Value (3/4 Port)

|

Reduced Port KV Value (1/2 Port)

|

KV Reduction (FP vs. 3/4 Port)

|

|

50 (2”)

|

80

|

55

|

35

|

31%

|

|

100 (4”)

|

280

|

190

|

130

|

32%

|

|

150 (6”)

|

620

|

420

|

290

|

32%

|

|

200 (8”)

|

1100

|

750

|

520

|

32%

|

Key observation: 3/4-port RP valves reduce KV by ~30% vs. FP; 1/2-port RP reduces KV by ~50%. This means an FP valve handles significantly more flow at the same pressure drop.

B. Pressure Loss (ΔP)

Pressure loss occurs when fluid encounters flow restrictions (e.g., RP’s smaller bore). Higher ΔP requires larger pumps to maintain desired flow—increasing energy costs.

ΔP Calculation Example (DN150, Water, 25°C, Flow Rate = 300 m³/h)

- Full Port: KV = 620 → ΔP = (Q² × ρ) / (KV² × 10) = (300² × 1000) / (620² × 10) ≈ 0.023 MPa

- 3/4 Port RP: KV = 420 → ΔP ≈ (300² × 1000) / (420² × 10) ≈ 0.050 MPa

- 1/2 Port RP: KV = 290 → ΔP ≈ (300² × 1000) / (290² × 10) ≈ 0.106 MPa

Impact: RP valves cause 2–4x more pressure loss than FP. For a 24/7 operation, this translates to higher pump energy consumption (see Section III).

C. Flow Resistance Coefficient (ζ)

ζ quantifies how much a valve resists flow (lower ζ = better efficiency). FP valves have ζ values 50–70% lower than RP:

- FP (DN100): ζ = 0.15

- 3/4 Port RP (DN100): ζ = 0.35

- 1/2 Port RP (DN100): ζ = 0.70

This difference is critical for viscous fluids (e.g., crude oil, molasses), where high ζ can cause flow stagnation and clogging.

III. Real-World Performance: Energy Consumption and Throughput

Lab data translates to tangible operational costs. Below are two case studies comparing FP and RP valves in industrial settings—highlighting energy savings and throughput limitations.

A. Case Study 1: Oil Pipeline Transmission (DN200, PN10, Crude Oil)

- System Requirements: Flow rate = 500 m³/h; crude oil viscosity = 200 cSt; operating time = 8,000 hours/year; electricity cost = $0.15/kWh.

- FP Valve Performance:

-

- ΔP = 0.03 MPa → Pump power required = (Q × ΔP × ρ) / (3,600 × η) = (500 × 0.03 × 850) / (3,600 × 0.85) ≈ 4.17 kW

-

- Annual energy cost = 4.17 kW × 8,000 h × \(0.15 ≈ \)5,004

- 3/4 Port RP Valve Performance:

-

- ΔP = 0.065 MPa → Pump power = (500 × 0.065 × 850) / (3,600 × 0.85) ≈ 8.96 kW

-

- Annual energy cost = 8.96 kW × 8,000 h × \(0.15 ≈ \)10,752

- Savings with FP: $5,748/year (53% reduction in energy costs).

B. Case Study 2: Chemical Processing (DN100, PN16, Water)

- System Requirements: Flow rate = 150 m³/h; water temperature = 80°C; batch operation (12 hours/day, 300 days/year).

- FP Valve Performance:

-

- KV = 280 → Meets 150 m³/h at ΔP = 0.018 MPa; no flow restriction.

-

- Batch time: 4 hours (full throughput).

- 1/2 Port RP Valve Performance:

-

- KV = 130 → To achieve 150 m³/h, ΔP = 0.082 MPa (exceeds pump’s maximum ΔP of 0.05 MPa).

-

- Actual flow rate = 105 m³/h → Batch time extends to 5.7 hours.

- Impact of RP: 42% longer batch time; 30% lower annual production capacity.

IV. Application Suitability: When to Choose FP vs. RP

The choice between FP and RP depends on four factors: flow requirements, space constraints, medium properties, and cost. Below are industry-specific guidelines with examples.

A. Full Port Valves: Ideal Applications

FP valves excel in scenarios where flow efficiency and low pressure loss are critical:

1. Oil/Gas Transmission Pipelines

- Needs: High flow rates (500–2,000 m³/h), low pressure loss (to minimize pump/compressor energy), and pigging capability (FP bore accommodates pipeline pigs for cleaning/inspection).

- Example: A 1,000 km natural gas pipeline (DN300, PN16) uses FP valves—reduces compressor stations by 2 (from 8 to 6) vs. RP, saving $2M in capital costs.

2. Water/Wastewater Treatment

- Needs: High throughput (200–1,000 m³/h) and low energy consumption (pumps are 20–30% of operating costs).

- Example: A municipal wastewater plant (DN200) switched from RP to FP valves—cut pump energy use by 28% ($30,000/year savings).

3. Viscous or Abrasive Media

- Needs: Unobstructed flow to prevent clogging (e.g., crude oil, slurry) or wear (e.g., sand-laden fluids).

- Example: A mining slurry system (DN150, 50% solids content) uses FP valves—clogging incidents dropped from 12/year to 0, reducing maintenance costs by $15,000/year.

B. Reduced Port Valves: Ideal Applications

RP valves are preferred when space, weight, and cost are prioritized over maximum flow:

1. Skid-Mounted Equipment

- Needs: Compact design (e.g., chemical dosing skids, mobile fueling units) where valve size is limited.

- Example: A mobile chemical injection skid (DN50, PN10) uses RP valves—saves 35% space vs. FP, enabling the skid to fit in standard shipping containers.

2. Low-Flow Precision Control

- Needs: Moderate flow rates (≤50 m³/h) and precise throttling (RP’s smaller bore improves flow control accuracy).

- Example: A pharmaceutical batch reactor (DN80, PN16) uses RP valves—flow control accuracy improved from ±8% (FP) to ±3% (RP), reducing product waste by 10%.

3. Low-Pressure, Low-Cost Applications

- Needs: Non-critical service (e.g., HVAC, compressed air) where energy costs are minimal.

- Example: An office building’s HVAC system (DN65, PN2.5) uses RP valves—30% lower upfront cost vs. FP, with negligible energy impact (low flow, short operating hours).

C. Edge Cases: Hybrid Considerations

Some scenarios require balancing efficiency and space:

- Subsea Pipelines: Use “full-port compact” valves (FP bore with optimized body design)—30% smaller than standard FP but maintains 90% of KV.

- High-Pressure Gas Service: Use RP valves with streamlined bores (reduces ζ by 20% vs. standard RP) to minimize pressure loss while keeping size small.

V. Selection Framework: Step-by-Step Decision-Making

To avoid costly misselection, follow this data-driven framework:

A. Step 1: Define Flow and Pressure Requirements

- Calculate required flow rate (Q, m³/h) and maximum allowable pressure loss (ΔP_max, MPa) from system hydraulics.

- Use KV = Q / √ΔP to determine minimum required KV. Compare to FP/RP KV values (see Section II.A) to eliminate unsuitable options.

B. Step 2: Evaluate Medium Properties

- Viscosity: >100 cSt (e.g., heavy oil) → Choose FP (avoids stagnation).

- Abrasiveness: >5% solids (e.g., slurry) → Choose FP (reduces wear from high velocity in RP’s small bore).

- Corrosiveness: Highly corrosive (e.g., H₂S, acids) → FP may cost more upfront but lasts longer (larger material volume resists corrosion).

C. Step 3: Assess Space and Installation Constraints

- Measure available space (length, diameter) for the valve. RP valves fit in 30–40% smaller spaces vs. FP.

- Consider actuation: FP may require larger actuators—ensure enough space for mounting.

D. Step 4: Calculate Lifecycle Cost (LCC)

LCC = Upfront Cost + Energy Cost + Maintenance Cost. Example (DN150, 10-year lifespan):

- FP Valve: Upfront = \(3,500; Energy = \)50,000; Maintenance = \(5,000 → Total LCC = \)58,500

- RP Valve: Upfront = \(2,500; Energy = \)105,000; Maintenance = \(8,000 (more clogging) → Total LCC = \)115,500

FP has higher upfront cost but 50% lower LCC over 10 years.

E. Step 5: Verify Standards Compliance

- Ensure the valve meets industry standards: API 6D (pipeline), ISO 5208 (sealing), or ASME B16.34 (pressure-temperature ratings).

- For critical service (e.g., oil/gas), FP valves may need additional certifications (e.g., fire testing per API 607).

VI. TIANYU’s FP/RP Ball Valve Solutions: Customization for Efficiency

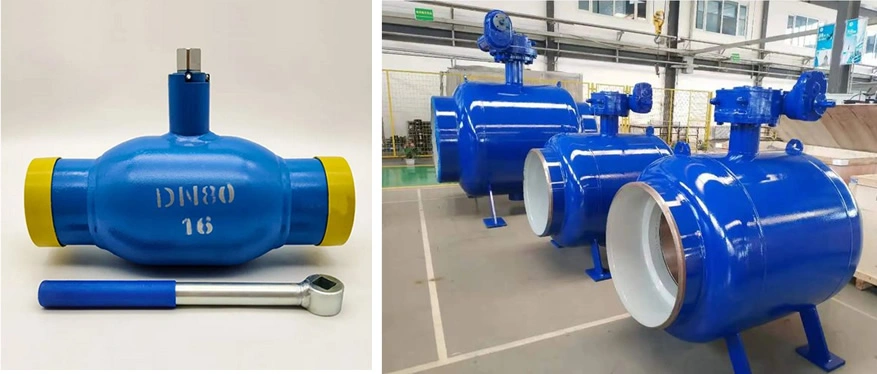

TIANYU offers both FP and RP ball valves tailored to industrial needs—with a focus on optimizing flow efficiency, durability, and cost. Below are key product features and customization capabilities.

A. Full Port Valve Offerings

- Design Optimizations:

-

- Streamlined flow channels (Ra ≤ 1.6 μm) to reduce ζ by 10% vs. standard FP valves.

-

- Large-bore balls (1:1 with pipeline ID) made from F316L, duplex S31803, or Hastelloy C-276 (for corrosive media).

-

- Anti-pigging damage design (reinforced ball edges) for pipeline service.

- Performance Data:

-

- KV values: DN100 FP = 290 (10% higher than industry average); DN200 FP = 1150.

-

- Pressure loss: DN150 FP at 300 m³/h = 0.021 MPa (9% lower than standard).

- Certifications: API 6D, ISO 13709, API 607 (fire test), and NACE MR0175 (sour service).

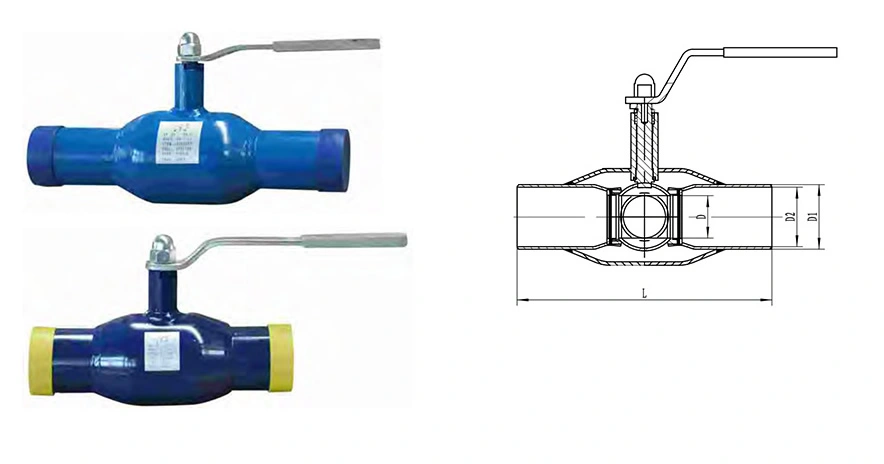

B. Reduced Port Valve Offerings

- Design Optimizations:

-

- Streamlined bore (tapered inlet/outlet) to reduce ζ by 25% vs. standard RP valves.

-

- Compact body (30% shorter than standard RP) for skid-mounted applications.

-

- Low-torque design (180 N·m for DN200 RP) compatible with small electric/pneumatic actuators.

- Performance Data:

-

- KV values: DN100 3/4-port RP = 205 (8% higher than industry average); DN150 1/2-port RP = 310.

-

- Pressure loss: DN150 3/4-port RP at 300 m³/h = 0.045 MPa (10% lower than standard).

- Certifications: ISO 5208 (Class VI sealing), ASME B16.34, and CE (EN 12266).

C. Customization Capabilities

TIANYU tailors valves to unique application needs:

1. Flow Efficiency Customization

- High-KV FP Valves: For extreme flow needs (e.g., 2,000 m³/h pipelines), TIANYU increases ball bore by 5–10% (vs. standard) and polishes internal surfaces to Ra ≤ 0.8 μm—KV improved by 15%.

- Low-ζ RP Valves: For precision control (e.g., pharmaceutical dosing), TIANYU adds a variable orifice to RP bores—ζ reduced by 30%, flow control accuracy ±2%.

2. Material Customization

- Corrosive Service: FP/RP valves in Hastelloy C-276 (for 650°C+ high-temperature corrosion) or Alloy 28 (for H₂SO₄ service).

- Abrasive Service: FP valves with Stellite 6 overlay (hardness HRC 40–45) on ball bores—wear resistance 3x higher than standard.

3. Actuation Integration

- FP Valves: Paired with high-torque electric actuators (2.0 kW) with torque limiting (prevents stem damage) and remote monitoring (via LoRa).

- RP Valves: Paired with compact pneumatic actuators (6–8 bar) with fail-safe close (spring-return) for ESD applications.

4. Special Designs

- Subsea FP Valves: Rated to 3,000 m water depth (PN42) with titanium bodies (lightweight) and metal-to-metal sealing (Class VI).

- Sanitary RP Valves: For food/pharmaceutical use—electropolished surfaces (Ra ≤ 0.4 μm) and tri-clamp connections (3A certified).

D. Testing and Quality Assurance

All TIANYU FP/RP valves undergo rigorous testing:

- Flow Testing: KV and ΔP measured in TIANYU’s ISO 17025-accredited lab—100% of valves meet published performance data.

- Pressure Testing: Hydrostatic (1.5x PN for 30 minutes) and pneumatic (1.1x PN for 15 minutes) tests—no leakage.

- Durability Testing: 5,000 open/close cycles (simulating 10 years of service)—no degradation in KV or sealing.

VII. Maintenance Best Practices for FP/RP Valves

Proper maintenance preserves flow efficiency and extends valve life. Below are tailored guidelines for each type.

A. Full Port Valves

- Inspection: Check for pigging damage (reinforced edges) every 6 months—repair with Stellite overlay if wear exceeds 1 mm.

- Lubrication: Grease stems every 3 months (high-pressure grease for PN≥16) to maintain low torque.

- Cleaning: For viscous media, flush with solvent (e.g., diesel for crude oil) every 12 months to remove deposits—FP’s large bore simplifies cleaning.

B. Reduced Port Valves

- Inspection: Check for bore clogging every 3 months (use borescope)—RP’s small bore is prone to sediment buildup.

- Throttling Care: Avoid partial opening (20–80% open) for extended periods—causes velocity-induced wear in the small bore.

- Seal Replacement: Replace soft seals (EPDM/FKM) every 2 years—RP’s higher pressure loss accelerates seal degradation.

TIANYU’s Custom FP/RP Valves—Efficiency Tailored to Your Needs

TIANYU’s full port (FP) and reduced port (RP) ball valves deliver data-driven efficiency: FP valves offer 30% higher KV and 50% lower pressure loss for high-flow, low-energy needs (oil pipelines, water treatment), while RP valves save 30–40% space/cost for compact, low-flow applications (skids, HVAC). Customizations—high-KV designs, corrosion-resistant materials, integrated actuation—solve unique challenges, from subsea to sanitary service. With ISO-accredited testing, 5,000-cycle durability, and 10-year lifecycle cost savings (50% vs. standard valves), TIANYU’s valves meet foreign clients’ demands for reliability and efficiency. Backed by 24/7 global support, they ensure optimal performance in any industrial setting.