II. Working Principles and Precision Coordination with Valve Systems

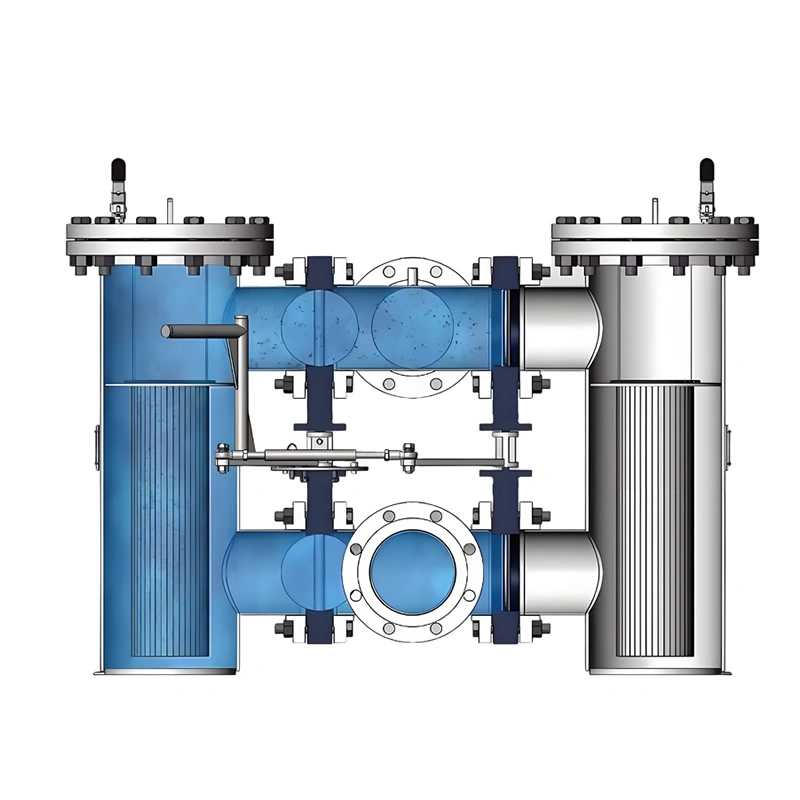

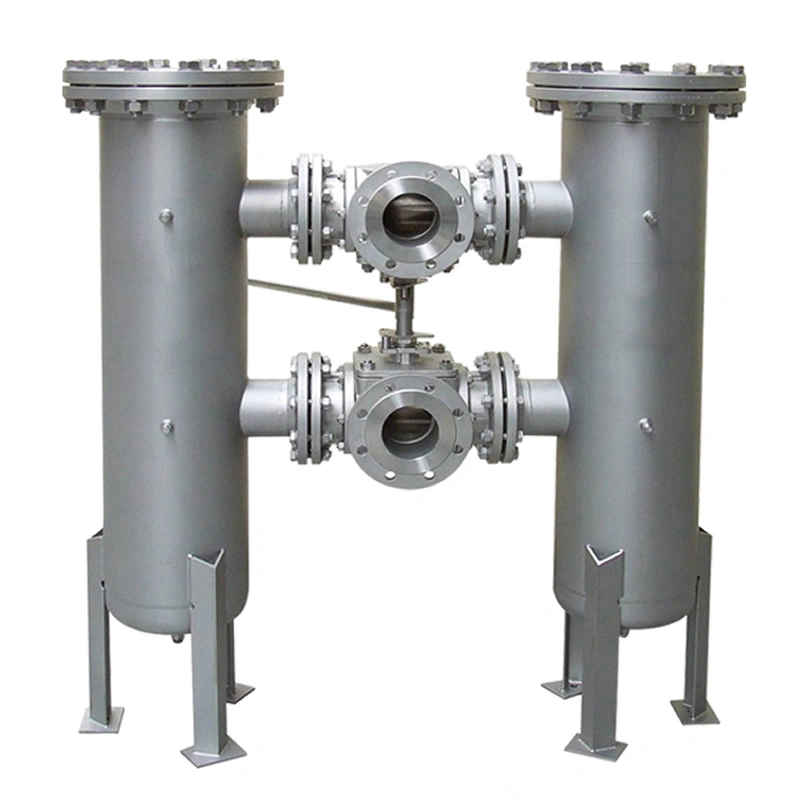

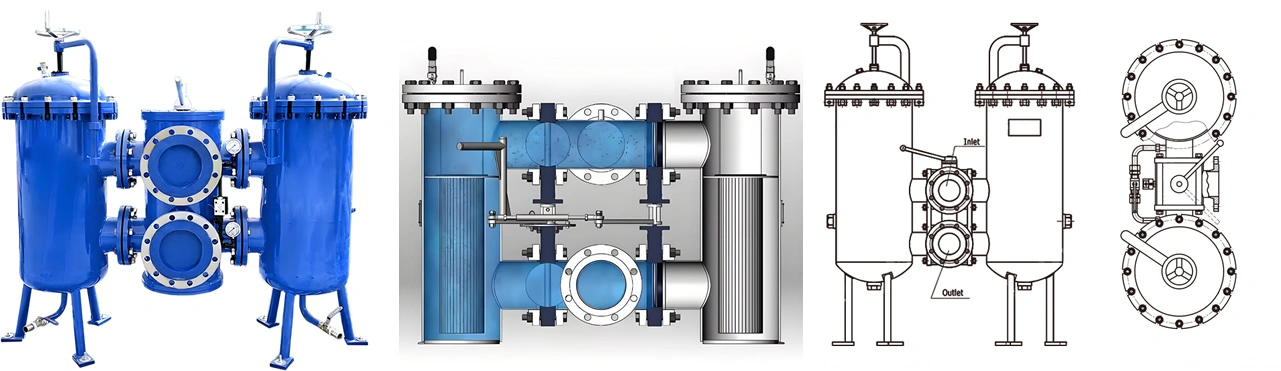

The operation of duplex filters is based on parallel redundancy and differential pressure control. Under normal conditions, fluid enters the system through the inlet pipe and is directed to one of the filter units via a three-way ball valve. As the fluid passes through the cartridge, suspended particles and impurities are captured, while clean fluid exits through the outlet.

When accumulated impurities increase the differential pressure across the filter cartridge, sensors detect this change. Once the preset threshold (typically 0.05–0.1 MPa) is reached, the control system triggers the cleaning cycle. Here, the valve system plays a critical role:

-

Three-Way Ball Valves redirect flow to the parallel filter unit.

-

Drain Valves open automatically to discharge waste during cleaning.

-

Inlet and Outlet Valves coordinate to isolate the unit requiring maintenance.

The backwashing process uses clean fluid reverse flow technology, where clean liquid flows backward through the cartridge to dislodge and remove accumulated debris. This process typically takes only seconds, restoring the cartridge’s filtration capacity before the system resumes normal operation.

TIANYU’s innovation lies in seamlessly integrating industrial valve technology with filtration processes. Its specialized three-way ball valves feature:

-

Low Flow Resistance Design: Optimized flow paths reduce pressure loss and energy consumption.

-

Rapid Actuation: Ensures quick switching between units with minimal process disruption.

-

High-Strength Sealing: Utilizes PTFE or metal seals for leak-free operation.

-

Multiple Actuation Options: Supports manual, pneumatic, or electric operation to suit varying automation needs.

This precise coordination between valves and filtration enhances system reliability and significantly improves cleaning efficiency and cartridge lifespan. Additionally, TIANYU systems offer multiple control strategies, including differential pressure triggering, timed triggering, and manual triggering, to meet diverse application requirements.

III. Application Areas and Adaptability to Multi-Media Processing

The flexibility of duplex filters enables them to adapt to various industrial environments and media types, demonstrating exceptional multi-media processing capabilities. Below is an overview of TIANYU duplex filter applications across industries:

-

Chemicals and Petrochemicals: Used to handle corrosive media like caustic soda, sulfuric acid, and acetic acid. TIANYU offers filter units made of special alloys (e.g., Hastelloy, titanium) and specialized seals for long-term stability in aggressive environments.

-

Water Treatment Systems: Applied in ultrapure water pretreatment, oilfield water injection, and circulating water treatment. These systems effectively remove suspended solids, microorganisms, and particulate matter to protect downstream equipment and membrane separation systems.

-

Food and Beverage Industry: Designed to meet strict hygiene standards, TIANYU provides GMP-compliant sanitary duplex filters with polished surfaces and dead-space-free designs to prevent product contamination. Typical applications include beverage water filtration, dairy processing, and syrup purification.

-

Pharmaceuticals and Biotechnology: Used for filtering pharmaceuticals, process water, and fermentation media. TIANYU offers integrity-testable cartridges and sterile-designed filtration systems to meet cGMP requirements.

-

Electronics and Power Industry: Critical for ultrapure water production and cooling water treatment in microelectronics manufacturing and power generation, protecting equipment and improving product quality.

The table below summarizes key application areas and technical highlights of TIANYU duplex filters:

Table: Applications and Technical Features of TIANYU Duplex Filters

| Application Area |

Typical Media |

Recommended Cartridge |

Filtration Precision |

Special Requirements |

| Chemical Processing |

Corrosive chemicals, solvents |

316L stainless steel, titanium |

1–50 μm |

Corrosion resistance, explosion-proof design |

| Oil & Gas |

Injection water, crude oil, slurry |

Metal sintered mesh, PP melt-blown |

5–100 μm |

High dirt capacity, high-pressure resistance |

| Food & Beverage |

Water, syrups, wines, dairy |

316L stainless steel, PP pleated |

0.5–25 μm |

Sanitary design, no dead zones |

| Pharma & Biotech |

Pharmaceuticals, pure water, fermentation media |

316L stainless steel, PTFE |

0.2–10 μm |

Sterile design, sterilizable |

| Electronics |

Ultrapure water, chemical reagents |

High-purity PP, PVDF |

0.1–5 μm |

Low extractables, low metal ions |

| Wastewater Treatment |

Industrial wastewater, circulating water |

Stainless steel mesh, woven wire |

50–400 μm |

High strength, wear resistance |

This broad applicability stems from TIANYU’s modular design and material diversity. Users can select the optimal configuration based on specific media characteristics (e.g., viscosity, corrosiveness, particle content, temperature) to achieve the best filtration efficiency and cost-effectiveness.

IV. Filter Cartridge Selection Strategy: Comparing 304 Stainless Steel vs. PP Cartridges

Filter cartridges, as the core filtering components, directly impact filtration efficiency, operational costs, and system reliability. TIANYU offers various cartridge materials, with 304/316L stainless steel and PP (polypropylene) cartridges being the most common options, each with distinct performance characteristics and suitable applications.

IV.I Technical Features of 304 Stainless Steel Cartridges

Made from high-quality stainless steel wire mesh or sintered stainless steel felt, these cartridges offer:

-

Excellent Mechanical Strength: Withstand high differential pressures and frequent backwashing without deformation or damage.

-

Superior Temperature Resistance: Operate continuously from -80°C to 450°C, suitable for high-temperature processes.

-

Outstanding Chemical Compatibility: Resist corrosion from various chemicals, especially in alternating acid-base environments.

-

Multiple Precision Levels: Range from 1 μm to 100 μm to meet different accuracy requirements.

-

Reusability: Can be reused multiple times via backwashing, offering a long service life.

Stain steel cartridges are ideal for high-temperature, highly corrosive, or frequently backwashed applications, making them the preferred choice in chemicals, petroleum, and pharmaceuticals.