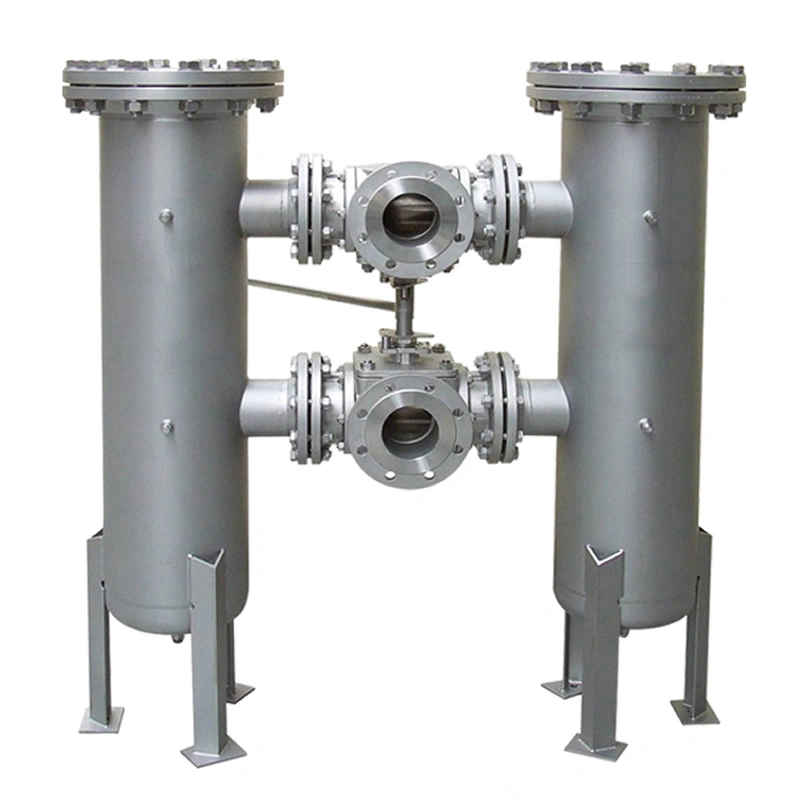

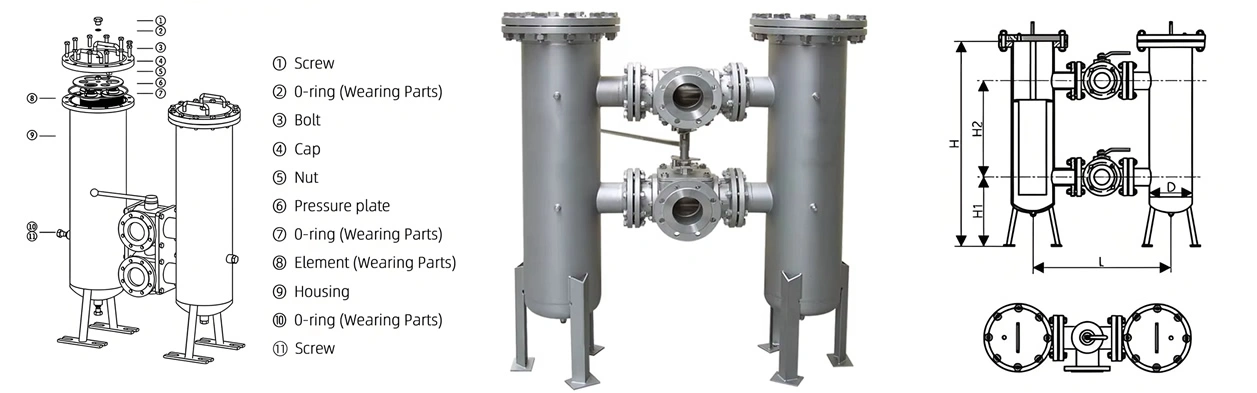

The core advantage of this strainer lies in its duplex configuration: two independent basket filters connected by 3-way valves. When one filter is in operation, the other can be isolated for cleaning, emptying, or basket replacement—eliminating the need to shut down the entire system. This is critical for continuous-process industries: in a petrochemical plant, for example, it ensures uninterrupted flow of crude oil while removing sediment; in a food beverage facility, it maintains production during screen cleaning, avoiding costly downtime. The 3-way valves feature precise flow diversion, with minimal pressure drop during switching, ensuring stable system pressure.

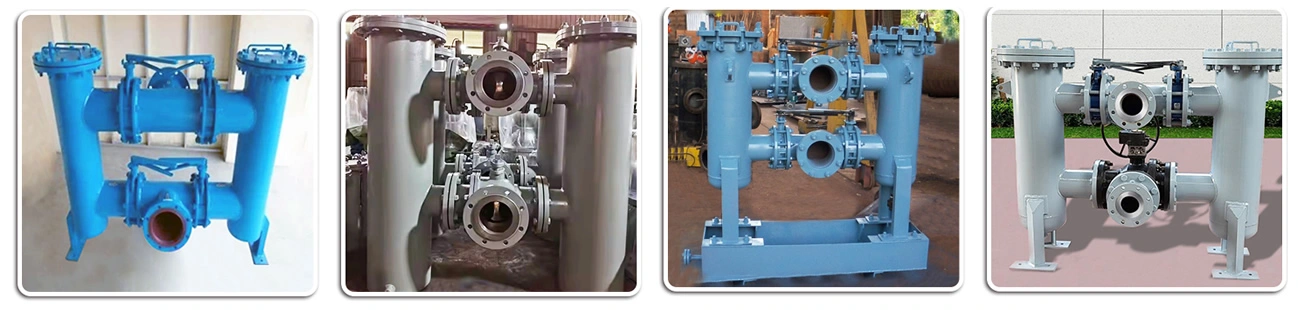

Constructed from 304 or 316 stainless steel, the filter excels in corrosive environments. 304 stainless steel, with 18% chromium and 8% nickel, forms a passive oxide layer resisting rust and mild chemicals—ideal for water treatment, dairy processing, or general industrial fluids. For harsher conditions (e.g., seawater, chlorinated water, or acidic solutions), 316 stainless steel (with molybdenum) provides superior pitting and crevice corrosion resistance, extending service life in offshore platforms or chemical processing lines. Both grades offer high tensile strength (≥515MPa), ensuring structural integrity under 40bar pressure.

Each filter chamber houses a stainless steel basket with a precision-woven mesh screen. The basket’s cylindrical design maximizes filtration area, allowing high flow rates with minimal pressure drop. Fine mesh (0.04μm) captures submicron particles in pharmaceutical or electronics manufacturing, while coarser mesh (1000μm) removes large debris (e.g., pipe scale, sediment) in water mains. The basket is supported by a perforated base, preventing mesh deformation under high flow velocities—a key feature in turbulent systems like pump discharge lines.

The filter’s cover features a quick-open design (bolt-on with handwheels or clamp-type) that allows rapid access to the basket. Unlike welded or flange-mounted covers, it can be opened in minutes, reducing maintenance time by 60% compared to traditional strainers. A vent valve releases trapped air during chamber re-pressurization, preventing water hammer; a drain valve simplifies debris removal during cleaning. This design is particularly valuable in industries with frequent filter checks, such as food processing (to maintain hygiene) or mining (to clear abrasive slurries).

The filter handles a wide range of media: liquids (water, oils, chemicals), gases (compressed air, natural gas), and slurries (low-solids). Its stainless steel construction and compatible gaskets (EPDM for water, Viton for oils/chemicals) resist degradation from most industrial fluids, avoiding media contamination. In hydraulic systems, it protects pumps and valves from particulate wear; in beverage production, it ensures product purity by removing sediment and foreign particles.

- Stainless Steel Sourcing: 304/316 stainless steel plates or billets are sourced from certified mills, with chemical composition verified via spectral analysis (e.g., 316: 16-18% Cr, 10-14% Ni, 2-3% Mo) to ensure corrosion resistance.

- Defect Detection: Raw materials undergo ultrasonic testing to identify internal flaws (porosity, cracks) that could compromise pressure integrity in high-pressure applications.

- Forming: Filter bodies and chambers are fabricated via forging (for high-pressure models) or precision welding (for large diameters). Forging enhances material density, critical for withstanding 40bar pressure; welded bodies are post-weld heat-treated to relieve internal stresses.

- Machining: Chamber interiors, valve ports, and connection surfaces are CNC-machined to tight tolerances (±0.05mm). Flange faces are ground to Ra ≤3.2μm for leak-tight sealing; threaded connections (NPT/BSPT) are precision-cut to ensure compatible assembly with pipes.

- Basket Construction: Stainless steel sheets are laser-cut and formed into cylindrical baskets, with perforated bases (1-3mm holes) for structural support. Seams are TIG-welded to prevent fluid bypass.

- Mesh Attachment: Woven/sintered stainless steel mesh is secured to the basket frame via crimping or welding. Mesh aperture is verified using a micrometer to ensure filtration precision (e.g., 50μm mesh checked for uniform opening size).

- 3-Way Valve Fabrication: Valves are machined from solid stainless steel, with precision-ground balls or plugs to ensure leak-free flow diversion. Seats are lapped to Ra ≤0.8μm for tight sealing.

- Final Assembly: Chambers are connected to 3-way valves via flanged or threaded joints. Quick-open covers are fitted with gaskets (EPDM/Viton) and hinge hardware. Vent/drain valves are installed to facilitate maintenance.

- Hydrostatic Test: Each filter is pressurized to 1.5×rated pressure (60bar for 40bar models) for 30 minutes, with no visible leakage or deformation.

- Filtration Efficiency Test: Challenged with standardized particles (e.g., glass beads) to verify ≥99% removal at rated micron size.

- Operation Test: 3-way valves are cycled 100+ times to ensure smooth switching; quick-open covers are tested for easy access and secure closure.