TIANYU DBB ball valves are engineered for versatility, with material, pressure, and drive options tailored to specific industry needs. Below are key applications across critical sectors:

The oil & gas sector demands valves that withstand high pressure, corrosive media (H₂S, saltwater), and hazardous environments—making DBB valves indispensable:

- Upstream (Exploration & Production):

- Wellheads & Christmas Trees: Class 1500-2500/F51 DBB valves with metal seals (Stellite 6) isolate high-pressure crude oil (up to 42MPa) and natural gas. NACE MR0175 compliance ensures resistance to H₂S-induced SCC.

- Chemical Injection Lines: DN15-DN50/F316 valves with PTFE seals regulate corrosion inhibitors and scale removers—preventing cross-contamination between chemicals.

- Midstream (Transmission & Storage):

- Pipeline Isolation: DN100-DN300/F316 DBB valves with full port and electric actuation control natural gas flow in cross-country pipelines. The bleed port allows safe pressure release before pigging operations.

- LNG Terminals: DN50-DN200/F51 valves with metal seals (-196℃~200℃) handle cryogenic LNG, ensuring leak-tightness and fire safety.

- Downstream (Refining & Petrochemical):

- Hydrocracker Units: Class 600/F316 DBB valves isolate H₂S-rich process streams—dual seals prevent toxic leaks, and anti-static features reduce explosion risks.

- Fuel Blending Lines: DN80-DN150/F304 valves with pneumatic actuation enable quick batch changes—Class VI sealing prevents cross-contamination between gasoline, diesel, and jet fuel.

Chemical plants handle aggressive media (acids, alkalis, solvents) and require strict batch separation—making DBB valves the preferred choice:

- Acid/Alkali Handling: DN25-DN100/F316 DBB valves with PTFE seals regulate sulfuric acid (98%), hydrochloric acid (37%), and sodium hydroxide (50%)—PTFE’s chemical inertness ensures no seal degradation.

- Pharmaceutical API Manufacturing: DN15-DN50/F316L valves with FDA-compliant PTFE seals and polished surfaces (Ra ≤0.8μm) prevent product contamination. The DBB design ensures no residual API mixes with new batches, complying with GMP standards.

- Polymer Production: DN100-DN200/F51 valves with metal seals handle high-temperature monomers (e.g., ethylene, propylene) up to 300℃—fire-safe design mitigates risks from flammable monomers.

Marine environments expose valves to saltwater (chlorides), wave-induced vibration, and harsh weather—requiring corrosion-resistant, high-strength materials:

- Offshore Wind Farms: DN80-DN150/F51 DBB valves with BW ends manage seawater cooling systems for turbines—F51’s chloride resistance prevents pitting, and flanged connections resist vibration.

- Shipbuilding: DN50-DN200/F316 valves with lever actuation control fuel oil, ballast water, and cooling water in commercial ships. Anti-static features reduce explosion risks in engine rooms.

- Offshore Platforms: Class 900-1500/F51 DBB valves with RTJ flanges isolate production fluids (crude oil, natural gas)—fire-safe design ensures reliability during deck fires.

Power plants require valves that withstand high temperatures (steam) and moderate pressure—with a focus on efficiency and safety:

- Thermal Power Plants: DN100-DN300/WCB DBB valves with metal seals regulate steam (up to 425℃) in boiler feedwater and turbine auxiliary lines. Full-port design minimizes pressure drop, reducing pump energy consumption.

- Nuclear Power Plants (Auxiliary Systems): DN50-DN150/F316 DBB valves with electric actuation control cooling water and chemical dosing—Class VI sealing prevents radioactive fluid leakage (in non-core systems).

- Renewable Energy (Biomass): DN80-DN200/F304 valves with PTFE seals handle biomass-derived syngas—preventing corrosion from acidic byproducts.

Municipal and industrial water treatment requires valves that resist chlorine, brackish water, and wastewater contaminants:

- Municipal Water Distribution: DN150-DN300/F304 DBB valves with FF flanges regulate potable water flow—F304’s corrosion resistance maintains water quality, and the bleed port allows pressure release before maintenance.

- Desalination Plants: DN100-DN250/F316 DBB valves with BW ends handle seawater and brine—molybdenum content resists chloride pitting, ensuring long service life.

- Industrial Wastewater: DN50-DN150/F316 valves with PTFE seals manage corrosive effluents (e.g., from metal plating or textile dyeing)—preventing leakage of toxic chemicals into the environment.

Sanitary standards (FDA, 3A, EHEDG) and product purity are paramount in food & beverage manufacturing:

- Dairy Processing: DN25-DN80/F316 DBB valves with polished surfaces (Ra ≤0.8μm) and FDA-compliant EPDM seals regulate milk, cheese, and yogurt flow—Class VI sealing prevents product contamination.

- Beverage Production: DN50-DN100/F304 valves with lever actuation control juice, soda, and beer flow—easy disassembly for CIP (Clean-in-Place) systems ensures hygiene.

- Edible Oil Refining: DN80-DN150/F316 valves with PTFE seals handle vegetable oil and biodiesel—resisting oxidation and ensuring product purity.

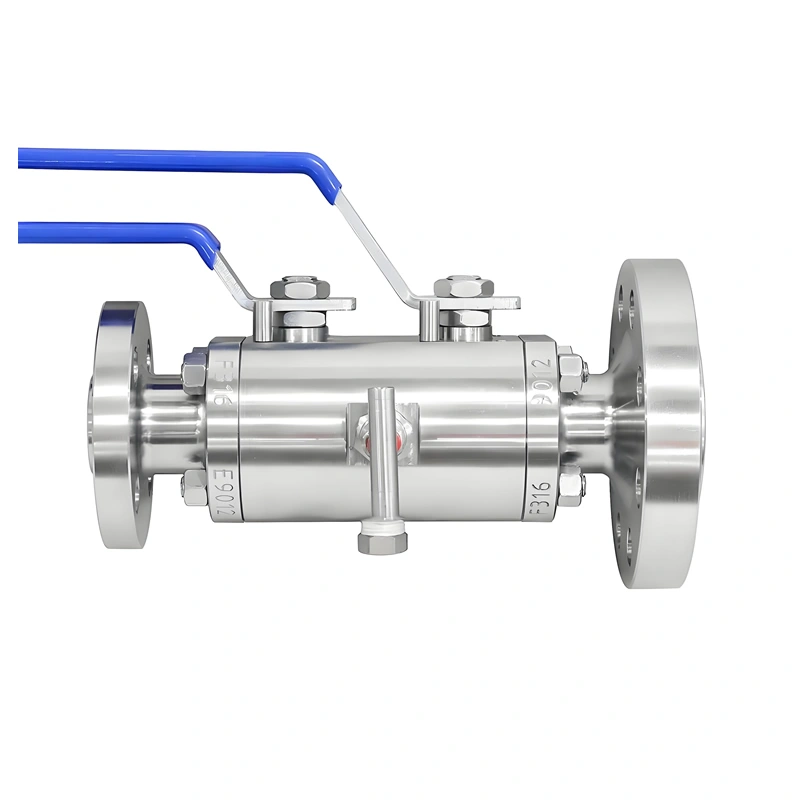

TIANYU Stainless/Duplex Steel Flanged DBB Ball Valve (DN15-DN300, Class 150-2500) delivers industry-leading safety, corrosion resistance, and compliance for oil, gas, chemical, marine, and sanitary applications. Its DBB design, premium materials (F304/F316/F51), and versatile actuation ensure reliable performance in high-pressure, corrosive, and hazardous environments—backed by API 6D/608, ASME B16.34, and global certifications.

To meet unique operational needs, the valve offers flexible customization options:

- Material Customization: 316L (low-carbon for welding), Hastelloy C276 (extreme corrosion), LCB (low-temperature carbon steel, -46℃), or WC6 (high-temperature alloy, 540℃) for specialized media/temperatures.

- Pressure/Temperature Extension: Class 4500/PN760 for ultra-high-pressure wellheads; metal seals with extended temperature range (-196℃~540℃) for LNG or steam applications.

- Drive Customization: Smart electric actuators with IoT connectivity (Modbus TCP/IP) for remote monitoring; explosion-proof pneumatic actuators (ATEX Zone 0) for highly flammable environments.

- Connection Customization: NPT/SW for small instrumentation lines; custom flange standards (JIS B2220, DIN 2543) for regional compatibility.

- Seal Customization: Food-grade EPDM (FDA 21 CFR 177.2600) for dairy/beverage; perfluoroelastomer (FFKM) for high-temperature chemicals (320℃).

- Certification Customization: SIL 3 for safety-instrumented systems (SIS); 3A/EHEDG for pharmaceutical/sanitary applications; NACE MR0175 for sour service.

By tailoring the valve to your specific media, pressure, and compliance needs, TIANYU ensures optimal performance, safety, and cost-effectiveness—making it a long-term investment for your industrial flow control requirements.