In industries where hygiene, purity, and product integrity are non-negotiable—such as food & beverage, pharmaceutical, and dairy—TIANYU’s Forged Stainless Steel Hygienic Flange Ball Valve stands as a precision-engineered flow control solution. Designed to meet the strictest global hygiene standards (3A, FDA 21 CFR 177.2600, ISO 2852) and industrial performance criteria (ASME B16.34, CE PED 2014/68/EU), this valve merges the structural strength of forged 304/316L stainless steel with a Hygiene – optimized design to eliminate media detention,prevent contamination, and ensure seamless on-off control.

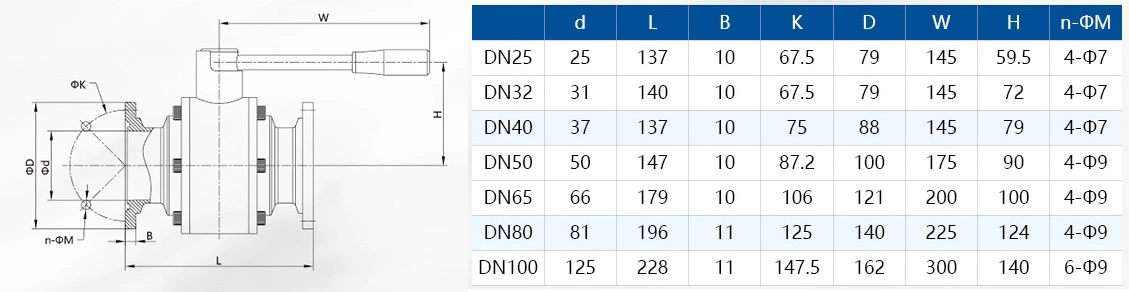

Crafted via precision forging (instead of casting, which risks porosity and contamination), the valve features a full-port, one-piece ball, PTFE (food-grade) soft seal, and flange connections compliant with ASME B16.5 (or DIN 11851 for European markets). The manual operation—via a ergonomic, lockable handwheel—delivers intuitive control without the need for external power, making it ideal for small to mid-scale hygiene-critical systems. Rated for nominal diameters from DN15 (1/2”) to DN100 (4”) and pressure ranges from PN10 (1.0MPa) to PN16 (1.6MPa), it operates reliably across temperatures from -20℃ to 150℃—covering most ambient and moderately heated hygienic processes (e.g., pasteurization, sterile filling).

What sets this valve apart is its commitment to “hygienic design principles”: smooth internal surfaces (Ra ≤0.8μm), no dead legs or crevices, and material compatibility with food-grade, pharmaceutical, and cosmetic media. Every component is selected to resist corrosion from acidic/alkaline process fluids (e.g., citrus juices, sanitizing agents) while maintaining non-toxic, non-reactive contact—critical for compliance with GMP (Good Manufacturing Practices) and HACCP (Hazard Analysis and Critical Control Points) protocols. As a trusted solution for hygiene-critical industries, it balances performance, durability, and regulatory compliance to minimize operational risks and ensure product safety.

Hygiene and corrosion resistance drive every material choice, with all wetted components meeting FDA and 3A standards for food/pharmaceutical contact:

- Valve Body & Bonnet: Forged Stainless Steel 304 (ASTM A182 F304) as standard; optional 316L (ASTM A182 F316L) for enhanced corrosion resistance. Forging eliminates internal defects (porosity, shrinkage) common in cast bodies, ensuring a dense, smooth structure. Chemical composition: 304 (Cr: 18–20%, Ni: 8–12%, C ≤0.08%); 316L (Cr: 16–18%, Ni: 10–14%, Mo: 2–3%, C ≤0.03%). Both alloys offer tensile strength ≥485MPa, yield strength ≥205MPa, and excellent resistance to chlorides, organic acids, and sanitizing agents (e.g., peracetic acid, chlorine dioxide).

- Ball: One-piece forged 304/316L stainless steel, full-port design. The ball’s surface is precision-polished to Ra ≤0.6μm to prevent media adhesion and facilitate thorough cleaning (CIP/SIP compatible). No welds or seams eliminate potential contamination points.

- Seat: Food-grade PTFE (Polytetrafluoroethylene, ASTM D4894) with FDA 21 CFR 177.1550 certification. PTFE is non-toxic, non-reactive, and resistant to most chemicals (acids, bases, solvents) and temperatures up to 150℃. Optional EPDM (ethylene propylene diene monomer) seats for high-temperature applications (up to 120℃) or FDA-compliant silicone for ultra-low temperature service (-40℃ to 120℃).

- Stem: Forged 304/316L stainless steel, anti-blowout design. The stem is polished to Ra ≤0.4μm to minimize friction with packing and prevent media entrapment. A keyway connection to the ball ensures secure torque transmission during operation.

- Packing: Food-grade PTFE-impregnated graphite packing, compliant with FDA standards. The multi-layer packing assembly provides leak-tight sealing (ANSI/FCI Class VI) while maintaining hygienic integrity—no contamination from packing materials.

- Flange & Fasteners: 304/316L stainless steel flanges (ASME B16.5 or DIN 11851) with raised face (RF) or flat face (FF) for hygienic gasket seating. Fasteners are 316L stainless steel bolts (ASTM A193 B8M) and nuts (ASTM A194 8M) to resist corrosion in washdown environments.

- Port Size (DN/NPS): DN15 (1/2”) to DN100 (4”), full-port design (bore diameter equal to nominal pipe size). This ensures unobstructed flow, minimizes pressure drop (Cv values from 15 for DN15 to 180 for DN100), and facilitates effective cleaning (CIP/SIP) by allowing full circulation of cleaning fluids.

- Pressure Rating: PN10 (1.0MPa) to PN16 (1.6MPa), aligned with ASME B16.34 pressure-temperature ratings for stainless steel valves. At 20℃, PN10 models handle 1.0MPa; PN16 models withstand 1.6MPa—suitable for low to medium-pressure hygienic systems (e.g., beverage filling lines, pharmaceutical transfer loops).

- Temperature Range: -20℃ to 150℃ (PTFE seats); -40℃ to 120℃ (silicone seats); 0℃ to 120℃ (EPDM seats). This covers most hygienic processes: cold storage (dairy), ambient filling (bottled water), and heated pasteurization (juices, sauces).

- End Connections: Hygienic flange (ASME B16.5 Class 150/300 or DIN 11851 Type A/B), designed for compatibility with standard hygienic pipelines. Flange faces are polished to Ra ≤1.6μm to ensure tight gasket sealing and prevent media leakage. Optional tri-clamp connections (DIN 32676) for quick-disconnect hygiene requirements.

- Face-to-Face Dimensions: Compliant with ISO 2852 (sanitary ball valves) and ASME B16.10, ensuring interchangeability with valves from other hygienic equipment manufacturers—simplifying replacement and retrofitting.

- Sealing Performance: ANSI/FCI 70-2 Class VI bubble-tight sealing (≤0.1×DN mm³/min for liquid media). The PTFE seat conforms to the polished ball surface, eliminating leakage of sterile or food-grade media—critical for preventing contamination and product loss.

- Operation Type: Manual, with a cast stainless steel handwheel (diameter 80mm–200mm, scaled to valve size). The handwheel features an anti-slip, grooved design for secure grip in wet/washdown environments. A lockable option (with padlock hole) prevents unauthorized operation—essential for GMP compliance.

- Operating Torque: 15N·m (DN15, PN10) to 120N·m (DN100, PN16). The full-port ball and low-friction PTFE seat minimize torque, enabling easy manual operation even for large-diameter valves (DN100).

- Hygiene Compliance:

- Surface Finish: Internal wetted surfaces (body cavity, ball, seat) polished to Ra ≤0.8μm; external surfaces polished to Ra ≤1.6μm to resist dirt buildup and facilitate washdown.

- CIP/SIP Compatible: Designed for Clean-in-Place (CIP) and Sterilize-in-Place (SIP) processes. No dead legs (≤2× pipe diameter), smooth flow paths, and no crevices to trap media—ensuring complete cleaning and sterilization.

- Material Compliance: All wetted components meet FDA 21 CFR 177.2600 (food contact), 3A 18-03 (dairy hygiene), and ISO 10993 (biocompatibility for pharmaceuticals).

- Hygiene Certifications: 3A Sanitary Standards, FDA 21 CFR 177.2600, ISO 2852 (sanitary ball valves), GMP (Good Manufacturing Practices).

- Industrial Standards: ASME B16.34 (valve dimensions/pressure-temperature), ASME B16.5 (flanges), ISO 5208 (leakage classification), CE PED 2014/68/EU (pressure equipment).

- Quality & Environmental Certifications: ISO 9001 (quality management), ISO 14001 (environmental management), RoHS (restriction of hazardous substances).