III. Feature Description

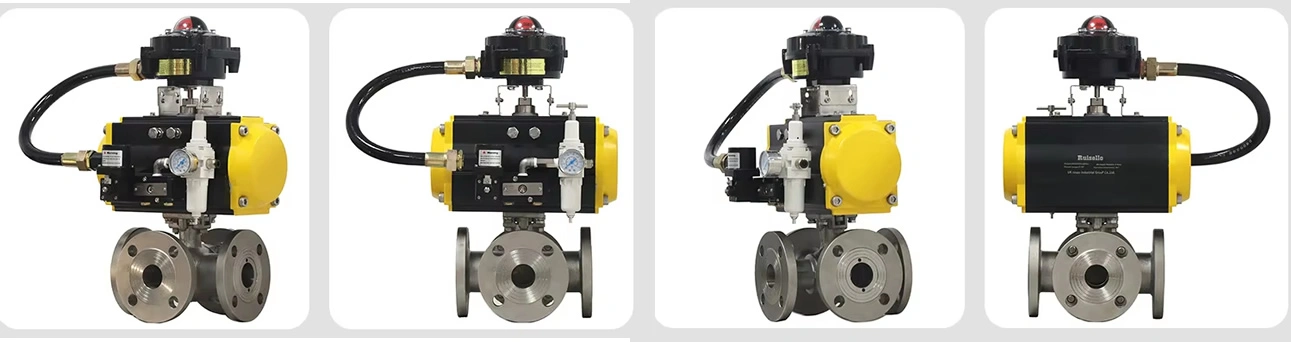

A. 4-Way Cross Design for Multi-Path Flow Control

The valve’s 4-way cross port configuration enables simultaneous management of two independent flow paths, eliminating the need for multiple 2-way or 3-way valves in complex systems. For example, in a chemical batch process, it can direct raw material from tank A to reactor B while diverting waste from reactor C to drain D—all with a single valve rotation. The precision-machined internal flow channels minimize pressure drop (Cv value 120~180 for DN80), ensuring efficient fluid transfer even when handling viscous media or slurries. This design simplifies pipeline layouts, reduces potential leak points, and lowers installation costs by up to 40% compared to multi-valve setups.

B. F316L Stainless Steel Corrosion Resistance

F316L stainless steel is the material of choice for applications involving aggressive media. Its molybdenum content enhances resistance to pitting and crevice corrosion in chloride-rich environments (e.g., seawater, brine, or chlorinated chemicals), outperforming 304 stainless steel in offshore or chemical processing settings. The low carbon content (≤0.03%) prevents sensitization during welding, avoiding intergranular corrosion—a critical feature for valves in high-purity systems like pharmaceutical manufacturing. The smooth, electropolished internal surfaces (Ra ≤0.8μm) prevent media adhesion and bacterial growth, meeting sanitary standards for food and beverage applications.

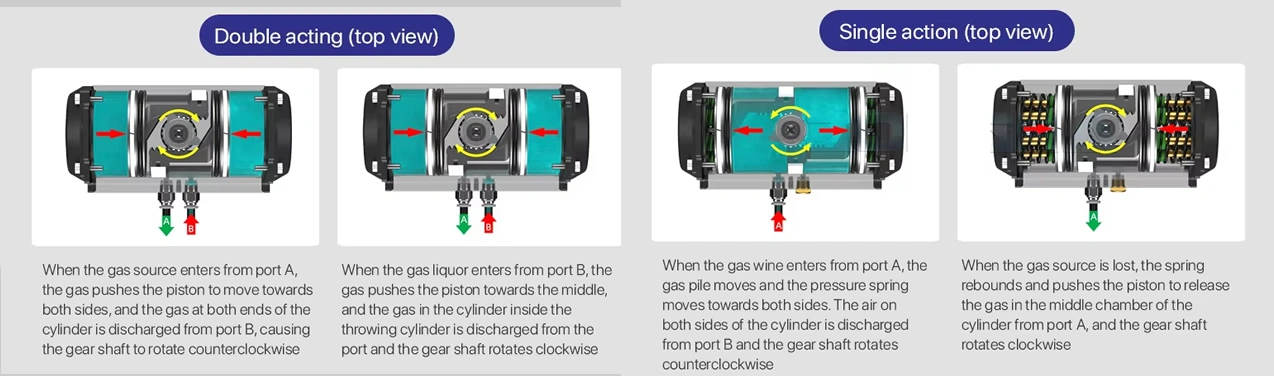

C. Pneumatic Actuation for Rapid, Automated Control

The pneumatic actuator enables fast, reliable flow switching, with 90° rotation completed in 5-10 seconds—essential for time-sensitive processes (e.g., emergency shutdowns in chemical plants). Double-acting actuators use air pressure for both opening and closing, ensuring consistent performance in high-cycle applications. Spring-return models provide fail-safe operation: if air supply is lost, the spring returns the valve to a pre-set position (open/closed), preventing hazardous media release. Optional positioners allow modulating control, adjusting flow rates proportionally to 4-20mA signals—ideal for precise mixing of chemicals or temperature regulation in industrial heating systems.

D. Bubble-Tight Sealing with PTFE/Metal Seats

PTFE seats offer chemical inertness and low friction, conforming to the ball’s surface to create a tight seal across the valve’s temperature range. This ensures zero leakage for gases, liquids, and semi-solids, critical for handling hazardous or high-value media (e.g., pharmaceutical ingredients). For high-temperature applications (up to 300℃) or abrasive slurries, stellite-coated metal seats provide wear resistance and thermal stability, maintaining sealing integrity even after prolonged exposure to extreme conditions. The seats are mechanically retained to prevent displacement under high flow velocities, a key feature in turbulent pipeline systems.

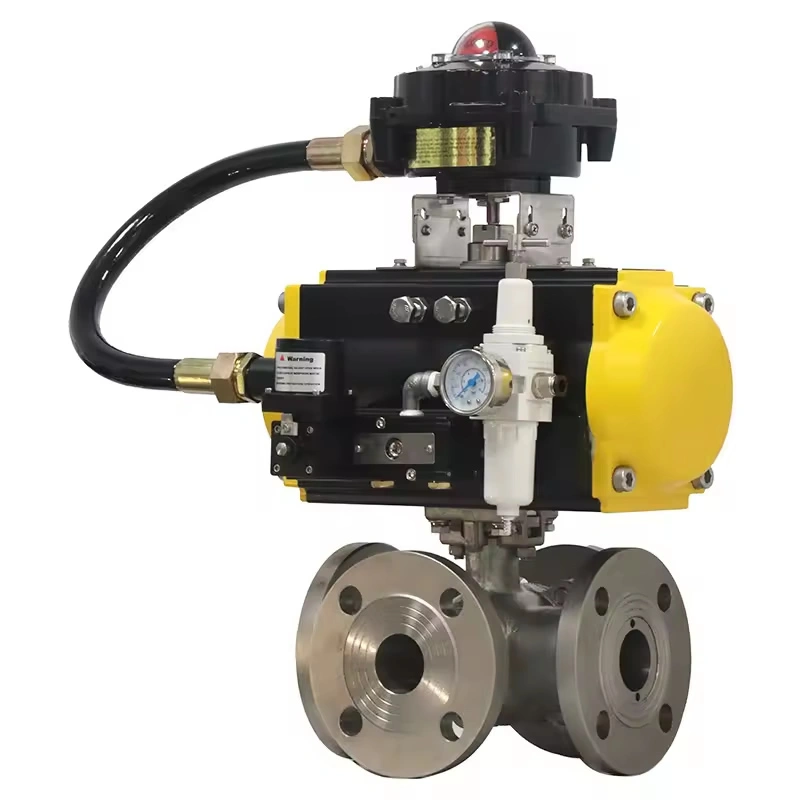

E. Flange Connection for Secure Integration

Flange connections (ASME B16.5) ensure compatibility with standard industrial pipelines, distributing pressure evenly across the sealing surface to prevent leakage. The raised face (RF) flange design enhances gasket contact, making it suitable for systems with pressure fluctuations (e.g., pump discharge lines). Flange mounting simplifies installation and maintenance—technicians can remove the valve without cutting into pipelines, reducing downtime during inspections or repairs. For high-vibration environments (e.g., offshore platforms), optional lockwashers secure flange bolts, preventing loosening over time.

IV. Manufacturing Processes

A. F316L Casting & Material Validation

- Investment Casting: Valve bodies and balls are precision-cast using the investment casting process, which produces complex shapes with tight tolerances (±0.05mm). This ensures uniform wall thickness and eliminates porosity, critical for pressure integrity.

- Material Testing: Cast components undergo spectral analysis to verify F316L composition (Cr, Ni, Mo content) and tensile strength testing (≥485MPa) to confirm mechanical properties.

B. Precision Machining

- Port & Flow Channel Machining: CNC milling centers shape the 4-way ports and internal flow channels, with surface grinding to achieve Ra ≤1.6μm—reducing turbulence and pressure drop.

- Ball Fabrication: The 4-way ball is CNC-turned and drilled to create cross-shaped flow paths, then lapped to Ra ≤0.8μm for uniform contact with seats.

- Flange & Stem Machining: Flange faces are machined to ASME B16.5 specs, with bolt holes drilled to precise positions. Stems are ground to fit packing chambers, ensuring smooth rotation without leakage.

C. Actuator Assembly & Calibration

- Actuator Integration: Pneumatic actuators are mounted to the valve via ISO 5211 pads, with drive shafts connected to the valve stem via spline couplings—ensuring precise 90° rotation alignment.

- Calibration: Actuators are tested for response time (5-10 seconds for 90° rotation) and position accuracy (±1°). Spring-return models are validated for fail-safe functionality during air loss.

D. Sealing System & Final Assembly

- Seat Installation: PTFE or metal seats are press-fitted into seat pockets, with retaining rings to prevent displacement. Seats are lapped against the ball to ensure bubble-tight contact.

- Packing Assembly: Graphite-impregnated PTFE packing is installed around the stem, compressed by a packing gland to balance leak resistance and actuator torque requirements.

E. Quality Testing

- Hydrostatic Test: The valve body is pressurized to 1.5×PN16 (2.4MPa) with water for 30 minutes, with no visible leakage or deformation.

- Gas Leak Test: Under 1.1×PN16 (1.76MPa) nitrogen pressure, leakage is measured to confirm ANSI/FCI Class V compliance.

- Cycle Test: 10,000+ open-close cycles are performed with pneumatic actuation to verify durability, with each flow configuration checked for proper sealing.