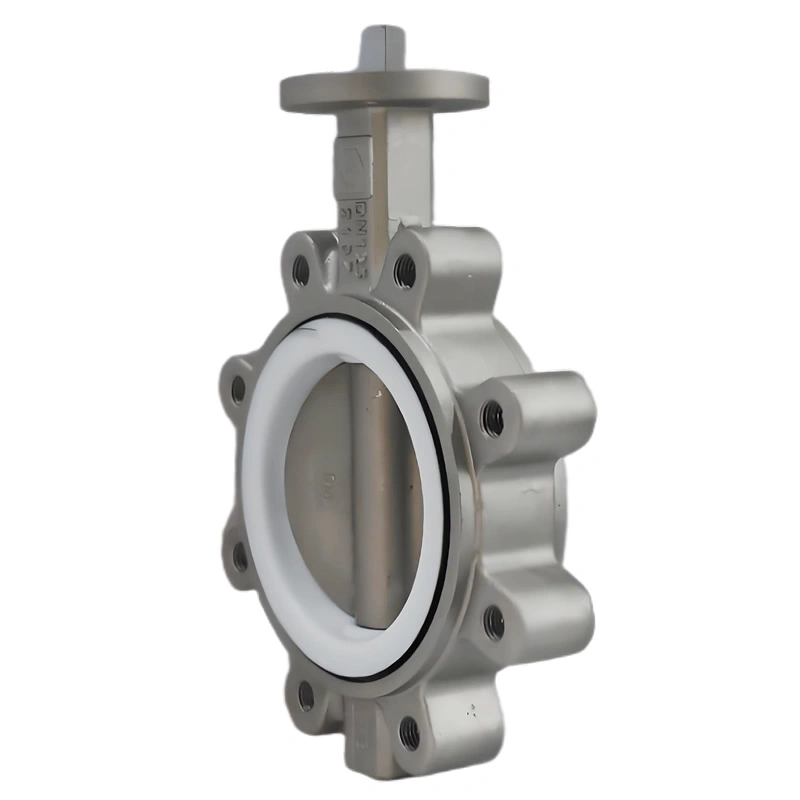

The midline design positions the disc symmetrically within the valve body, ensuring that the disc edges make equal contact with the PTFE seat during closure. This symmetry eliminates uneven wear and provides consistent, bubble-tight sealing (ANSI/FCI Class VI) across the valve’s service life. In chemical dosing systems, for example, this design prevents costly media leakage and ensures precise flow control.

Additionally, the midline disc minimizes flow restriction, with a flow coefficient (Cv) of approximately 350 for a DN125 valve. This efficiency reduces pump energy consumption by up to 15% compared to valves with offset disc designs, making it a cost-effective choice for energy-conscious operations.

CF8M (316 stainless steel) is the material of choice for applications involving chlorides, sulfuric acid, and other corrosive media. In a seawater desalination plant, for instance, a CF8M valve would maintain integrity for over 10 years, whereas a 304 stainless steel valve would corrode within 2–3 years. The alloy’s molybdenum content enhances its resistance to pitting and crevice corrosion, critical for maintaining sealing performance in aggressive environments.

The valve body and disc undergo solution annealing (heat treatment) to restore corrosion resistance after machining, ensuring the material’s full chemical and mechanical properties are retained. This process is particularly important for valves exposed to high-temperature or high-pressure corrosive media, such as in chemical reactors or pharmaceutical sterilization loops.

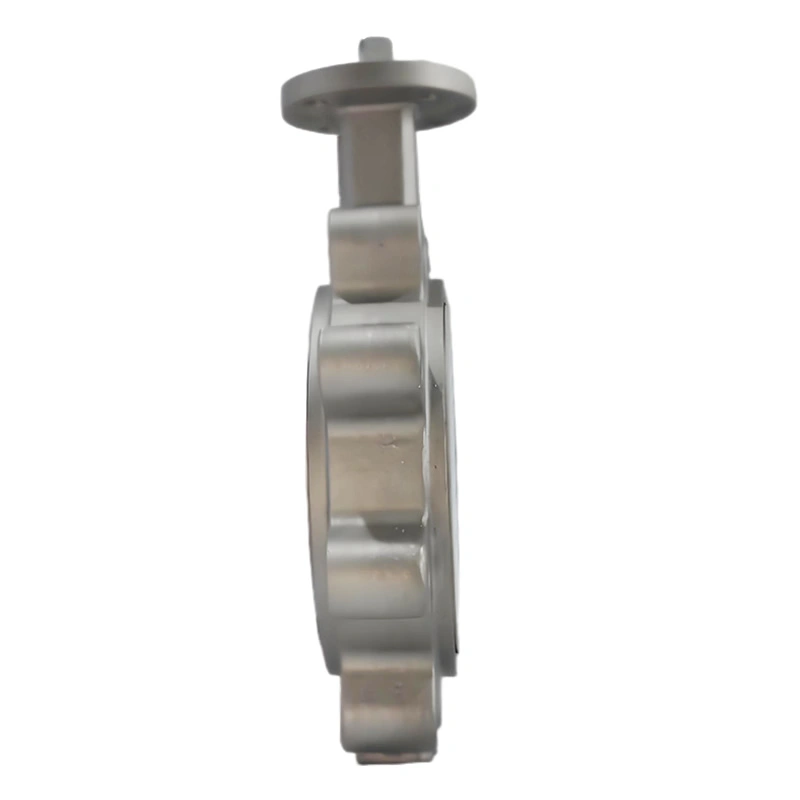

Lug-type flanges offer distinct advantages over wafer or wafer-style flanges:

- Bolt-Through Installation: Lug flanges are drilled to allow bolts to pass through the valve and into the pipeline flanges, simplifying alignment and reducing installation time. This is especially beneficial in confined spaces or when retrofitting into existing pipelines.

- Isolation Capability: Lug valves can be installed with blind flanges on one side, enabling easy isolation for maintenance without disrupting the entire pipeline system. In a pharmaceutical batch processing line, this feature allows for quick valve replacement or inspection, minimizing downtime.

- Compatibility: Lug flanges conform to ASME B16.5, ensuring compatibility with standard pipeline flanges from other manufacturers. This interchangeability reduces inventory costs and streamlines procurement for multi-vendor projects.

PTFE’s chemical resistance is unparalleled, making it suitable for handling nearly all industrial chemicals, including strong acids (e.g., hydrochloric acid), alkalis (e.g., sodium hydroxide), and organic solvents (e.g., acetone). In a chemical plant’s acid waste treatment system, a PTFE-lined valve would resist degradation, whereas an unlined valve would corrode within weeks.

The PTFE lining also maintains its properties at temperatures up to 180℃, making it suitable for hot chemical processing or sanitary applications involving steam sterilization. Unlike rubber seals, PTFE does not degrade or swell in contact with aggressive media, ensuring long-term sealing reliability.

The soft-sealed design, with PTFE contacting the disc, achieves ANSI/FCI Class VI leakage performance—meaning “zero leakage” for practical purposes. This is critical for applications where media containment is essential, such as in pharmaceutical manufacturing (to prevent product contamination) or hazardous chemical handling (to avoid environmental spills).

Even under cyclic operation and temperature fluctuations, the PTFE seal retains its elasticity and sealing integrity. In a water treatment plant’s disinfection loop, for example, the valve maintains leak-tight performance after 10,000+ cycles, demonstrating its durability in demanding conditions.

- CF8M Verification: Raw material billets undergo spectral analysis to confirm chemical composition (Cr: 16–18%, Ni: 10–12%, Mo: 2–3%) and ultrasonic testing to detect internal defects. Mechanical testing (tensile, impact) ensures compliance with ASTM A351 standards.

- PTFE Lining Material Testing: PTFE sheets are tested for density, tensile strength, and chemical resistance to ensure they meet FDA and industrial-grade requirements.

- Casting: The valve body and disc are produced via investment casting for CF8M stainless steel, ensuring dimensional accuracy and a smooth surface finish. Castings are solution-annealed to restore corrosion resistance.

- Machining: CNC turning and milling centers shape the body, disc, and lug flanges. Flange faces are machined to flatness tolerance ≤0.05mm/m and surface finish Ra ≤3.2μm for proper gasket seating. The disc’s sealing edge is precision-ground to ensure uniform contact with the PTFE lining.

- Preparing the Substrate: The valve body and seat surfaces are sandblasted to create a rough texture, enhancing PTFE adhesion.

- Lining Application: PTFE is applied via spray coating or press-fitting, depending on the valve size and complexity. For a DN125 valve, the lining thickness is typically 2–3mm, with a tolerance of ±0.2mm to ensure uniform coverage.

- Curing: The lined valve is heated in an oven to cure the PTFE, ensuring it bonds securely to the stainless steel substrate.

- Component Assembly: The disc, stem, and sealing components are assembled into the valve body. The stem is torqued to ensure proper disc alignment and sealing pressure.

- Hydrostatic Testing: The valve undergoes shell and seat tests at 1.5× and 1.1× rated pressure, respectively, with no leakage allowed.

- Operational Testing: The valve is cycled 100 times to verify smooth operation, torque consistency, and seal integrity. Leakage is measured using a bubble counter to confirm ANSI/FCI Class VI performance.