In the petrochemical industry, valves are used to control fluid flow, pressure, and prevent accidents. They are capable of enduring high temperatures and pressures in refinery environments, ensuring safe and smooth operation of processes.

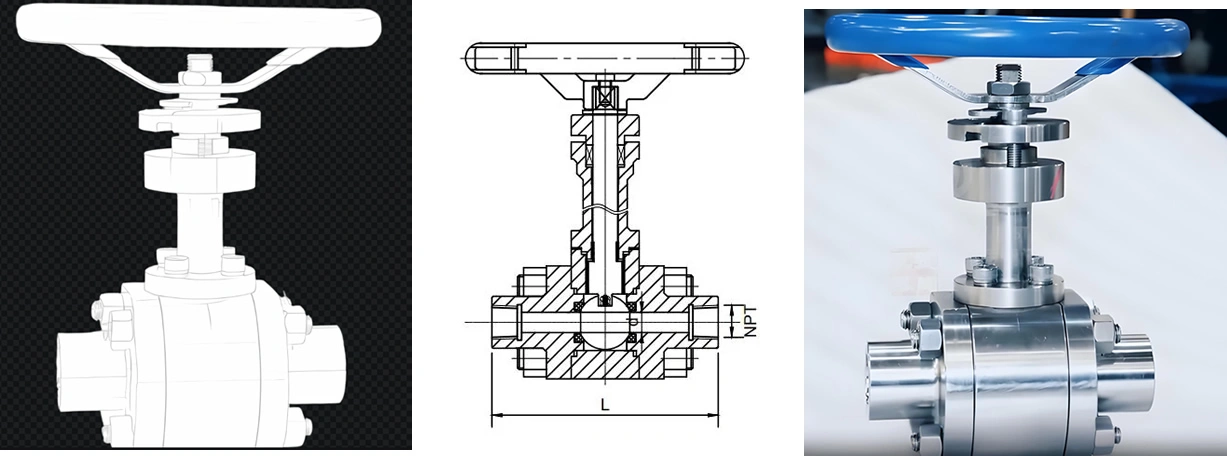

TIANYU’s API 608-certified A105 forged steel 3PC ball valve delivers robust, reliable flow control for oil & gas, petrochemical, and industrial sectors. Forged A105 construction, floating ball design, and flexible sealing ensure durability, tight sealing, and adaptability to -29℃–425℃ temperatures. Customize it: opt for F316 (corrosion resistance), RTJ flanges (high pressure), Stellite overlay (abrasion), or electric actuation (remote control). Tailored to your media and system needs, it balances safety, compliance, and cost-effectiveness—your trusted critical-service valve solution.