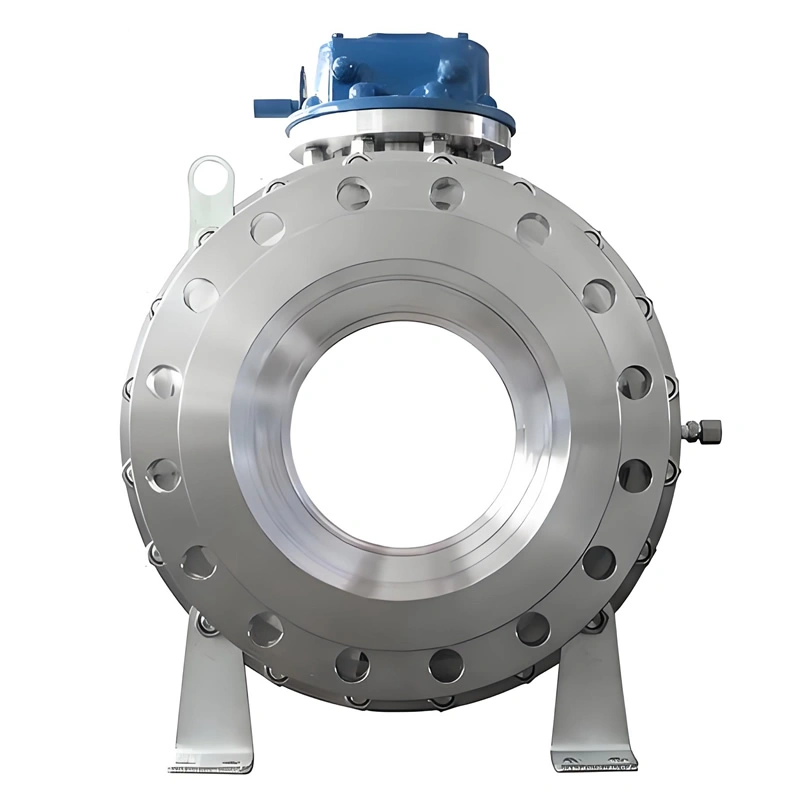

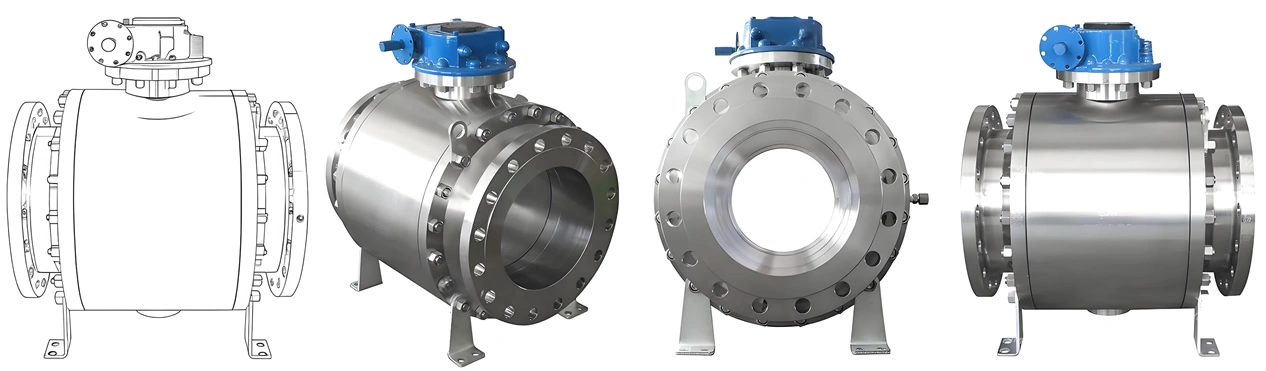

The three-piece body configuration is a defining advantage for industrial operators: unlike one-piece or two-piece valves, which require removal from the pipeline for internal service, the TIANYU 3PC valve can be disassembled by unbolting its three segments. This allows technicians to access the ball, seat, and stem without disconnecting adjacent piping—reducing maintenance downtime by up to 70% in critical processes (e.g., petrochemical reactor feed lines, where unplanned shutdowns cost $10k+ per hour).

The bolted segments also enable easy replacement of worn components (e.g., seals, ball) without replacing the entire valve, lowering long-term maintenance costs. For facilities with limited space (e.g., offshore platforms), this design eliminates the need for heavy lifting equipment to remove large-diameter valves.

The trunnion-mounted (fixed-ball) design addresses a key limitation of floating-ball valves: in high-pressure systems (Class 300+), floating balls transfer pressure forces to the seats, increasing operational torque and accelerating seat wear. TIANYU’s trunnion design supports the ball via upper and lower shafts, directing pressure forces to robust bearings instead of the seals.

This structure reduces operational torque by 40–50% compared to floating-ball valves, enabling easier manual operation or smaller (lower-cost) actuators for automated models. In Class 600 DN300 applications (e.g., offshore oil wellheads), it maintains consistent sealing integrity over 10,000+ cycles—twice the service life of comparable floating-ball valves.

For industries handling flammable media (oil, gas, chemicals), fire safety is non-negotiable. The TIANYU valve’s fire-safe system complies with API 607 7th Edition: during a 30-minute fire test (exposure to 750℃), the primary PTFE seal melts, but the expanded graphite secondary seal swells to fill gaps, while the metal-to-metal seat ring provides a backup barrier. Post-test leakage remains below API 607 limits, preventing flammable media escape and secondary explosions.

This feature is mandatory for many oil & gas and petrochemical applications (e.g., refinery distillation lines) and aligns with global safety regulations (e.g., OSHA in the U.S., ATEX in the EU).

SS316/SS304 materials deliver dual benefits: corrosion resistance and hygienic compatibility. SS316’s molybdenum content resists chloride-induced pitting (critical for coastal/offshore applications or seawater cooling systems), while its non-porous surface prevents media contamination—making it suitable for food & pharmaceutical facilities (compliant with FDA 21 CFR 177.2600).

In a coastal chemical plant test, SS316 valves showed no corrosion after 5 years of seawater service, while carbon steel valves failed within 18 months. For high-purity applications (e.g., pharmaceutical API manufacturing), the polished SS316 ball/stem eliminates dead spaces where bacteria or contaminants could accumulate.

Quality control begins with rigorous raw material validation:

- Stainless Steel Verification: SS316/SS304 bar stock undergoes spectral analysis (XRF) to confirm chemical composition (e.g., 16–18% Cr, 2–3% Mo for SS316) and ultrasonic testing (UT) to detect internal defects (porosity, cracks). Material Test Reports (MTRs) are generated for every batch.

- Seal Material Testing: Reinforced PTFE is tested for hardness (Shore D 55–65) and thermal stability; expanded graphite is evaluated for expansion rate (≥200% at 750℃) to ensure API 607 compliance.

- Fastener Validation: ASTM A193 B8M bolts undergo tensile strength testing (≥550MPa) to confirm load capacity.

- 3PC Body Machining: SS316/SS304 bar stock is cut into three segments (two end caps, one middle body) and machined via 5-axis CNC centers. Flange faces are precision-machined to ASME B16.5 flatness (≤0.05mm/m) and surface finish (Ra ≤3.2μm) for proper gasket seating. The middle body’s trunnion bearing bores are honed to ±0.02mm tolerance to ensure ball alignment.

- Ball & Trunnion Processing: The SS316 ball is turned, then ground with a spherical grinder to achieve a surface finish of Ra ≤0.2μm (critical for bubble-tight sealing). Trunnions are machined integrally with the ball, then heat-treated and polished to reduce bearing friction.

- Seat Ring Manufacturing: SS316 seat rings are machined, then fitted with reinforced PTFE and expanded graphite layers via compression molding.

Assembly is performed in a Class 10,000 cleanroom to prevent contamination:

- Trunnion & Ball Installation: The ball (with integral trunnions) is inserted into the middle body, and bearings (PTFE-impregnated bronze) are pressed into the trunnion bores.

- Seal & Body Assembly: Seat rings are installed in the end caps, then the three body segments are bolted together with controlled torque (per ASME B18.2.1) to ensure uniform seal compression.

- Actuator Mounting: Manual/worm gear actuators are attached via ISO 5211 flanges, with laser alignment to ensure stem-trunnion coaxiality (runout ≤0.05mm). Automated actuators (pneumatic/electric) are calibrated to 4–20mA signals, with limit switches set to trigger at fully open/closed positions.

Every valve undergoes multi-stage testing:

- Hydrostatic Testing: Per API 598—shell test (1.5× rated pressure, 30 minutes) for body integrity; seat test (1.1× rated pressure, 15 minutes) for leak-tightness (≤1 bubble/minute for Class VI).

- Fire Testing: Random samples undergo API 607 testing (30-minute 750℃ exposure + post-fire leakage assessment).

- Operational Testing: 100 open-close cycles to verify torque consistency and actuation speed (3–5 seconds for pneumatic models).

- Non-Destructive Testing (NDT): Liquid penetrant testing (PT) for flange welds; magnetic particle testing (MPI) for trunnions.

| Pressure |

150LB |

300LB |

600LB |

900LB |

1500LB |

2500LB |

|

| Strength Testing |

3.0 |

7.5 |

15.4 |

23.0 |

37.5 |

63.0 |

Mpa |

| Seal Testing |

2.2 |

5.5 |

11.2 |

16.9 |

27.5 |

46.2 |

| Air Testing |

0.6 |

0.6 |

0.6 |

0.6 |

0.6 |

0.6 |

Post-test, each valve receives a unique serial number, and documentation (MTRs, test reports, certifications) is packaged with the unit.