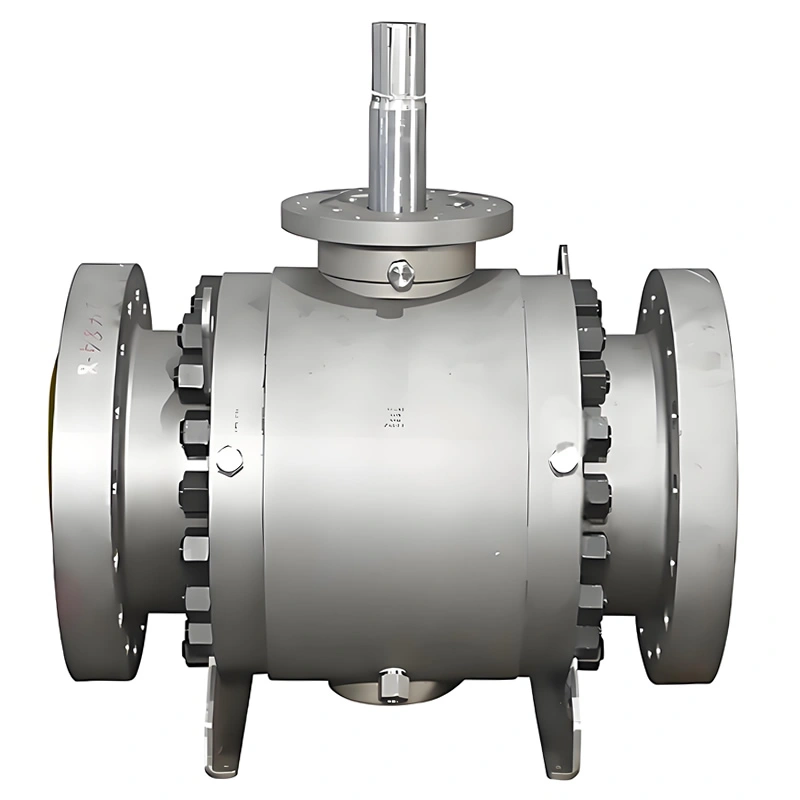

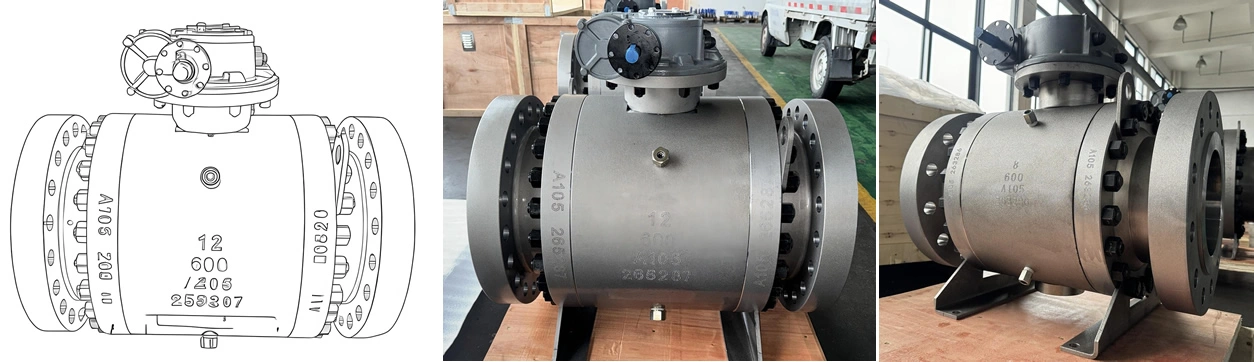

In the high-stakes realm of industrial fluid control—where reliability under extreme pressure, corrosion resistance, and long-term durability are non-negotiable—TIANYU’s Forged Trunnion Mounted 3PC Flange Ball Valve stands as a precision-engineered solution tailored for critical applications. Designed and manufactured in strict compliance with global industry standards including API 6D (Pipeline Valves), API 608 (Steel Ball Valves), and ASME B16.34 (Valves, Flanges, Fittings and Gaskets for Pressure Piping), this valve merges the structural integrity of forged carbon steel A105 and stainless steel F316 with a trunnion-mounted design to deliver uncompromising performance in oil & gas, petrochemical, chemical processing, and power generation sectors.

Crafted via precision forging (eliminating porosity and defects common in cast alternatives), the valve features a three-piece (3PC) body structure, full-port flow design, and PTFE sealing system—ensuring bubble-tight closure, low operational torque, and easy maintenance. Rated for nominal diameters from DN50 (2”) to DN800 (32”) and pressure ranges spanning 50LB (PN6) to 2500LB (PN420), it operates reliably across temperatures from -29℃ to 425℃—covering everything from ambient liquid transfer to high-temperature steam service.

The manual operation, via a robust worm gear handwheel, delivers intuitive, tool-free control without dependency on external power sources—ideal for remote locations or systems where automation is unnecessary. Key safety features including anti-static devices, fire-safe design (API 607), and double block & bleed (DBB) functionality further enhance its suitability for hazardous and critical service. As a trusted product from a leading manufacturer, it balances performance, compliance, and cost-effectiveness, making it a cornerstone of fluid control systems worldwide.

Every component is selected to withstand harsh industrial conditions, with material compatibility tailored to pressure, temperature, and media requirements:

- Valve Body, Bonnet & End Flanges: Forged Carbon Steel A105 (ASTM A105) as standard—an industry workhorse with chemical composition (C: 0.25–0.35%, Mn: 0.60–1.05%, P/S ≤0.035%) delivering tensile strength ≥485MPa, yield strength ≥240MPa, and impact toughness ≥27J at -20℃. Optional forged stainless steel F316 (ASTM A182 F316) for enhanced corrosion resistance in chloride-rich environments (e.g., seawater, chemical processing).

- Ball: Forged Stainless Steel F304/F316 (ASTM A182), with full-port design to minimize pressure drop. The ball surface is precision-lapped to Ra ≤0.4μm for uniform sealing contact, and optional ENP (Electroless Nickel Plating) is available for extreme wear resistance in abrasive media (e.g., slurries, sand-laden oil).

- Stem: Forged Stainless Steel F304/F316 (ASTM A276), featuring an anti-blowout design to prevent ejection under high pressure. The stem undergoes solution annealing and polishing (Ra ≤0.4μm) to reduce friction with packing, ensuring smooth operation and minimizing fugitive emissions.

- Seat: Dual-seat design with A105/F316 metal base and PTFE (Polytetrafluoroethylene) insert—complying with FDA 21 CFR 177.1550 for chemical inertness. PTFE delivers ANSI/FCI Class VI bubble-tight sealing, while optional Viton or graphite seats accommodate high-temperature (up to 425℃) or fire-safe service. Seat springs (Inconel X-750 or F304) provide constant preload for self-compensating sealing as wear occurs.

- Trunnion & Bearings: F304/F316 stainless steel trunnions supported by PTFE-impregnated bronze bearings—reducing operational torque and ensuring smooth ball rotation even after prolonged inactivity.

- Packing & Gaskets: Multi-layer graphite packing with PTFE inner ring (complying with ISO 15848-1 Class AH for low fugitive emissions). Bonnet gaskets are spiral-wound graphite with F304/F316 metal reinforcement, ensuring tight sealing under thermal cycling and pressure fluctuations.

- Fasteners: A193 B7 carbon steel bolts (for A105 bodies) or A193 B8M stainless steel bolts (for F316 bodies) with A194 2H/8 nuts—providing uniform clamping force and corrosion resistance.

- Port Size (DN/NPS): DN50 (2”) to DN800 (32”), full-port design (bore diameter equal to nominal pipe size) to optimize flow efficiency. Cv values range from 120 (DN50) to 15,000 (DN800), minimizing pressure drop and energy consumption in high-flow applications.

- Pressure Rating: 50LB (PN6), 150LB (PN20), 300LB (PN50), 600LB (PN100), 900LB (PN160), 1500LB (PN250), 2500LB (PN420)—aligned with ASME B16.34 pressure-temperature ratings. At 20℃, 2500LB models withstand 42MPa, making them suitable for high-pressure oil & gas transmission.

- Temperature Range: -29℃ to 425℃ (standard PTFE seats); -46℃ to 538℃ (graphite seats for fire-safe service). Low-temperature variants (A350 LF2 material) extend service to -196℃ for cryogenic applications (e.g., LNG transfer).

- End Connections: Flange (ASME B16.5 for DN50-DN600, ASME B16.47 for DN650-DN800) with Raised Face (RF) or Ring Type Joint (RTJ) sealing surfaces. Optional butt-weld (BW) ends (ASME B16.25) for permanent, leak-tight pipeline integration.

- Face-to-Face Dimensions: Compliant with API 6D and ASME B16.10, ensuring interchangeability with valves from other manufacturers—simplifying replacement and retrofitting in existing systems.

- Sealing Performance: ANSI/FCI 70-2 Class VI (PTFE seats) for liquid media, with leakage rate ≤0.1×DN mm³/min. Metal-seat variants (graphite) achieve Class IV sealing, suitable for high-temperature and fire-safe service.

- Operation Type: Manual, via worm gear operator with cast iron handwheel (diameter 150mm–600mm, scaled to valve size). The worm gear design reduces operational torque by 5–8×, enabling single-person operation of large-diameter valves (e.g., DN800 2500LB). A lockable handwheel prevents unauthorized operation—critical for safety in hazardous environments.

- Operating Torque: 50N·m (DN50, 50LB) to 1500N·m (DN800, 2500LB)—optimized by the trunnion-mounted design, which transfers media pressure loads to the trunnions (not the seats).

- Safety Features:

- Anti-static Device: Stainless steel spring creates a conductive path between ball, stem, and body—dissipating static electricity to prevent sparking in flammable media.

- Fire-Safe Design: Complies with API 607 (7th edition) and BS 6755—graphite backup seals expand during fire to maintain sealing integrity if PTFE seats degrade.

- Double Block & Bleed (DBB): Isolates the valve cavity in fully open/closed positions, allowing trapped media to be bled—preventing overpressure and enabling safe maintenance.

- Anti-Blowout Stem: Shoulder design engages with the bonnet to prevent stem ejection under extreme pressure—meeting API 6D safety requirements.

- Design & Performance Standards: API 6D, API 608, ASME B16.34, ASME B16.5, ASME B16.47, ISO 14313 (Pipeline Ball Valves), API 598 (Valve Inspection and Testing).

- Safety & Quality Certifications: CE (PED 2014/68/EU), ISO 9001:2015 (Quality Management System), NACE MR0175 (for sour service), EN10204 3.1/3.2 (Material Test Certificates).

- Environmental Compliance: ISO 15848-1 Class AH (fugitive emissions), RoHS (Restriction of Hazardous Substances), REACH (EU Chemical Regulations).