The three-piece body configuration is a defining advantage for industrial operators, addressing the core pain point of downtime in critical processes:

- In-Line Disassembly: Unlike one-piece or two-piece valves, which require complete removal from the pipeline for maintenance, the TIANYU 3PC valve can be disassembled by unbolting its three segments (two end caps + one middle body). This allows technicians to access the ball, seat, and stem without disconnecting adjacent piping—reducing maintenance time by 70% compared to one-piece valves. For example, in a petrochemical refinery’s DN300 600LB process line, replacing worn seats takes 2 hours (vs. 8 hours for a one-piece valve), avoiding $80k+ in lost production.

- Uniform Seal Compression: The bolted body segments enable controlled torque application (per ASME B18.2.1), ensuring uniform compression of the seat seals. This eliminates uneven wear and extends seal life by 2–3×, critical for high-cycle applications (e.g., gas pipeline shut-off valves).

- Structural Rigidity: The split-body design enhances rigidity for large-diameter, high-pressure valves (DN600 1500LB), preventing body deformation under extreme pressure loads.

The trunnion-mounted design solves a key limitation of floating-ball valves: in high-pressure systems, floating balls transfer pressure forces to the seats, increasing operational torque and accelerating seat wear. TIANYU’s fixed-ball design delivers:

- Pressure Force Distribution: The ball is supported by upper and lower trunnions, which transfer fluid pressure forces to robust PTFE-impregnated bronze bearings. This eliminates seat deformation, even in 1500LB (PN250) service, maintaining consistent sealing over 10,000+ cycles.

- Low Operational Torque: Trunnion support reduces friction between the ball and seats by 40–50% compared to floating-ball valves. A DN600 600LB worm gear model requires only 200 N·m of torque—enabling manual operation without specialized tools.

- Bidirectional Reliability: The fixed-ball design ensures symmetric sealing in both flow directions, eliminating installation direction constraints. This simplifies pipeline layout for oil & gas midstream transmission, where flow direction may reverse during maintenance.

For industries handling flammable media (oil, gas, chemicals), fire safety is mandatory. The valve’s fire-safe system is engineered to API 607 7th Edition standards:

- Dual-Seal Design: During normal operation, the reinforced PTFE/PPL primary seal delivers ANSI/FCI Class VI bubble-tight leakage. In a fire event (750℃ exposure), the PTFE melts, and the expanded graphite secondary seal swells to fill gaps, while the 316 stainless steel seat ring forms a metal-to-metal backup seal.

- Post-Fire Performance: After 30 minutes of API 607 fire testing, the valve maintains leakage below 0.1×DN mm³/min—preventing flammable media escape and secondary explosions. This compliance is mandatory for offshore platforms, refineries, and chemical plants operating under OSHA or ATEX regulations.

- Anti-Static Protection: A conductive spring connects the ball, stem, and body to dissipate static charges (common in gas flow), eliminating spark risks that could ignite flammable vapors.

The valve’s carbon steel and stainless steel variants are tailored to diverse application needs:

- Carbon Steel (A105N/WCB): Cost-effective for non-corrosive media (water, crude oil, natural gas) in 150LB–1500LB service. A105N forged carbon steel offers superior tensile strength (485–655MPa) for high-pressure upstream oil wellheads, while WCB cast carbon steel is ideal for midstream pipeline valves.

- Stainless Steel (F316/CF8M): Corrosion-resistant for harsh media (seawater, acids, chlorides) in coastal/offshore or chemical processing applications. F316’s molybdenum content resists pitting corrosion, making it suitable for seawater cooling systems or sour gas service (with NACE MR0175 compliance).

- Material Compatibility: Both variants work with a range of seal materials (PTFE, PPL, PTFE+carbon fiber) to match media characteristics—e.g., PPL for high-temperature hydrocarbons, PTFE+glass fiber for abrasive fluids.

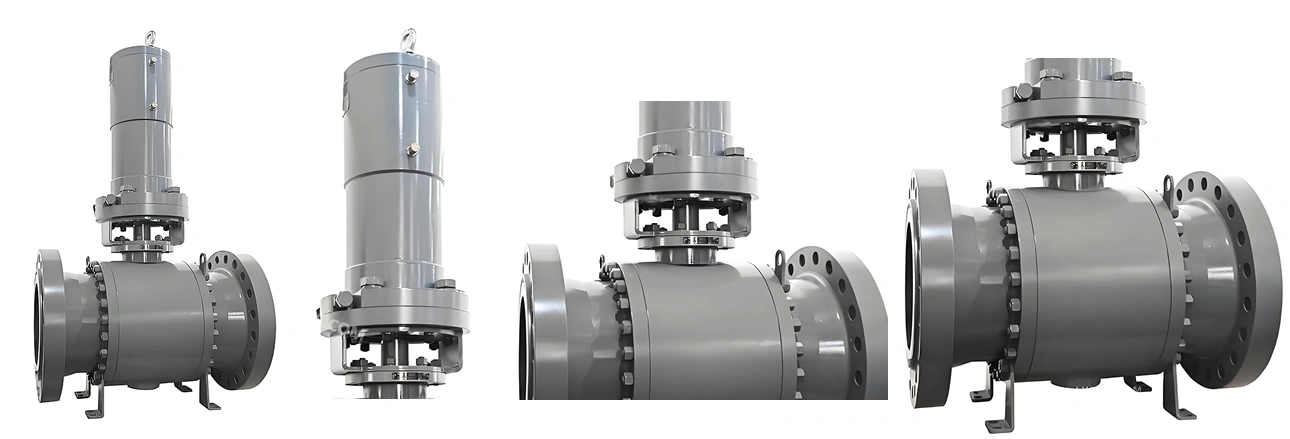

The valve supports manual, pneumatic, and electric actuation to align with diverse process control requirements:

- Manual/Worm Gear: Ideal for low-cycle, remote applications (e.g., pipeline isolation valves) where power is unavailable. The worm gear operator’s self-locking design prevents accidental valve movement due to vibration.

- Pneumatic (Double-Acting/Spring-Return): Fast-acting (3–5 seconds) for automated process lines (e.g., petrochemical reactor feed valves). Spring-return models provide fail-safe operation (auto-close/auto-open) on air supply loss—critical for emergency shutdown systems (ESD).

- Electric: Remote-controllable for large-scale facilities (e.g., refineries, power plants) with SCADA/DCS integration. The IP67-rated actuator withstands harsh industrial environments (dust, moisture), while the 4–20mA positioner enables precise position monitoring.

Flange connections (ASME B16.5/ASME B16.47) deliver practical advantages for industrial pipelines:

- Leak-Tight Sealing: Bolted flanges distribute clamping force evenly across spiral-wound gaskets, ensuring integrity under pressure/temperature fluctuations. RTJ flanges (optional for 900LB+) use metal ring gaskets for ultra-high-pressure service, eliminating fugitive emissions.

- Standard Compatibility: Compliance with ASME B16.5 ensures compatibility with existing pipeline flanges, reducing retrofitting costs. For example, a DN300 300LB valve can replace an aging valve without modifying pipeline flanges.

- Easy Installation: Flange alignment is simplified via precision-machined bolt holes, reducing installation time by 30% compared to welded valves. This is critical for offshore platforms or tight-space industrial facilities.

Quality control begins with rigorous validation of raw materials to ensure compliance with ASTM/API standards:

- Carbon Steel Verification: A105N billets and WCB castings undergo spectral analysis (XRF) to confirm chemical composition (C: 0.25–0.35% for A105N) and ultrasonic testing (UT) to detect internal defects (porosity, cracks). Mechanical testing (tensile strength, impact resistance) ensures compliance with ASTM A105/A216, documented in Material Test Reports (MTRs).

- Stainless Steel Validation: F316/CF8M bar stock is tested for chromium, nickel, and molybdenum content (16–18% Cr, 2–3% Mo for F316) via XRF spectroscopy. Salt spray testing (ASTM B117) confirms corrosion resistance (≥1000 hours without pitting).

- Seal Material Testing: Reinforced PTFE is tested for hardness (Shore D 55–65) and thermal stability (220℃ for 1000 hours); expanded graphite is evaluated for expansion rate (≥200% at 750℃) to ensure API 607 compliance.

- Fastener Validation: ASTM A193 B7/B8M bolts undergo tensile strength testing (≥827MPa for B7) and thread verification (ASME B1.1) to ensure load capacity.

- 3PC Body Machining:

- Carbon steel/stainless steel bar stock is cut into three segments (end caps, middle body) via CNC sawing.

- 5-axis CNC machining centers precision-machine flange faces to ASME B16.5 flatness (≤0.05mm/m) and surface finish (Ra ≤3.2μm). Trunnion bearing bores are honed to ±0.02mm tolerance to ensure ball alignment.

- Body segments undergo shot blasting (SA 2.5) to remove scale and surface impurities, then coated with epoxy paint (carbon steel models) or passivated (stainless steel models) for corrosion protection.

- Ball & Trunnion Processing:

- Solid F316/A105N ball blanks are turned via CNC lathes, then ground with spherical grinders to achieve a surface finish of Ra ≤0.2μm—critical for bubble-tight sealing.

- Trunnions are machined integrally with the ball, then heat-treated (carburizing for carbon steel, solution annealing for stainless steel) and polished to reduce bearing friction.

- Seat Ring Manufacturing:

- 316 stainless steel seat rings are machined, then fitted with reinforced PTFE/PPL and expanded graphite layers via compression molding. The seat ring’s outer diameter is precision-machined to ensure interference fit with the body’s seat pocket.

Assembly is performed in a Class 10,000 cleanroom to prevent contamination of sealing surfaces:

- Trunnion & Ball Installation: The ball (with integral trunnions) is inserted into the middle body, and PTFE-impregnated bronze bearings are pressed into the trunnion bores. Bearings are lubricated with high-temperature grease (resistant to 200℃) for long-term smooth operation.

- Seal & Body Assembly: Seat rings are installed in the end caps, then the three body segments are bolted together with torque-controlled wrenches (per ASME B18.2.1) to ensure uniform seal compression.

- Stem & Packing Installation: The 316 stainless steel stem is inserted into the body, and graphite-impregnated PTFE packing is installed in layers (5–7 layers) with controlled compression (10–15%) to balance sealing and torque.

- Actuator Mounting: Manual/worm gear actuators are attached via ISO 5211 flanges, with laser alignment to ensure stem-trunnion coaxiality (runout ≤0.05mm). Pneumatic/electric actuators are calibrated to 4–20mA signals, with limit switches set to trigger at fully open/closed positions.

Every valve undergoes multi-stage testing to meet API/ASME standards and industrial safety requirements:

- Hydrostatic Testing (API 598):

- Shell test: 1.5× rated pressure (e.g., 22.5MPa for 600LB) for 30 minutes, with no leakage, sweating, or deformation.

- Seat test: 1.1× rated pressure (e.g., 16.5MPa for 600LB) for 15 minutes, with leakage measured via bubble counting (≤1 bubble/minute for Class VI).

- Fire Testing (API 607): Random samples undergo 30-minute exposure to 750℃ propane flames, followed by a seat test to confirm post-fire leakage compliance.

- Operational Testing: 100 open-close cycles to verify torque consistency, actuation speed (3–5 seconds for pneumatic models), and position accuracy.

- Non-Destructive Testing (NDT):

- Liquid penetrant testing (PT) for flange welds and body segments to detect surface cracks.

- Magnetic particle testing (MPI) for trunnions and stem to ensure structural integrity.

- Ultrasonic testing (UT) for forged components (A105N) to detect internal defects.

- Fugitive Emissions Testing (ISO 15848-1): The stem and body-bonnet joint are tested for methane emissions, meeting Class BH standards (≤100 ppmv).

Post-test, each valve receives a unique serial number, and documentation (MTRs, test reports, certifications) is packaged with the unit for traceability.