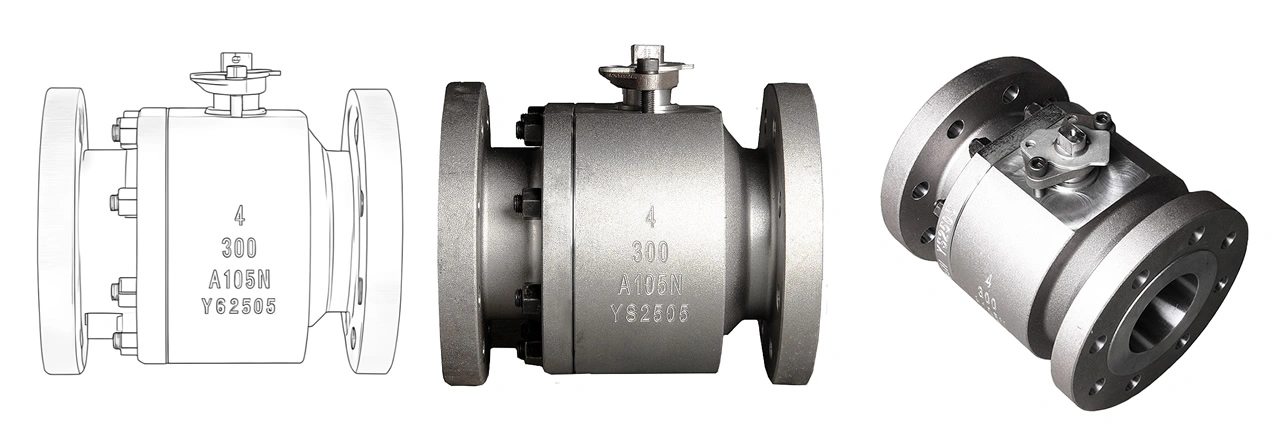

In the industrial fluid control landscape, forged steel

ball valves stand as a robust, reliable solution for high-pressure, high-temperature, and harsh media applications—combining structural integrity, corrosion resistance, and long-term performance. TIANYU’s A105 Forged Steel 3PC

Floating Ball Valve, engineered to comply with API 608 (Steel Ball Valves), ASME B16.34 (Valves for Pressure Piping), and CE PED 2014/68/EU standards, is tailored for critical service in oil & gas, petrochemical, power generation, and general industrial sectors.

Crafted from A105 forged carbon steel—an industry workhorse renowned for its exceptional tensile strength, impact toughness, and thermal stability—the valve features a three-piece (3PC) body design, floating ball configuration, and versatile sealing options (PTFE/EPDM/metal) to accommodate media ranging from natural gas and crude oil to steam and mild corrosives. The 3PC structure enables on-line maintenance without removing the valve from the pipeline, while the floating ball design relies on media pressure to achieve bubble-tight sealing—ensuring leak-free operation even under fluctuating pressure conditions.

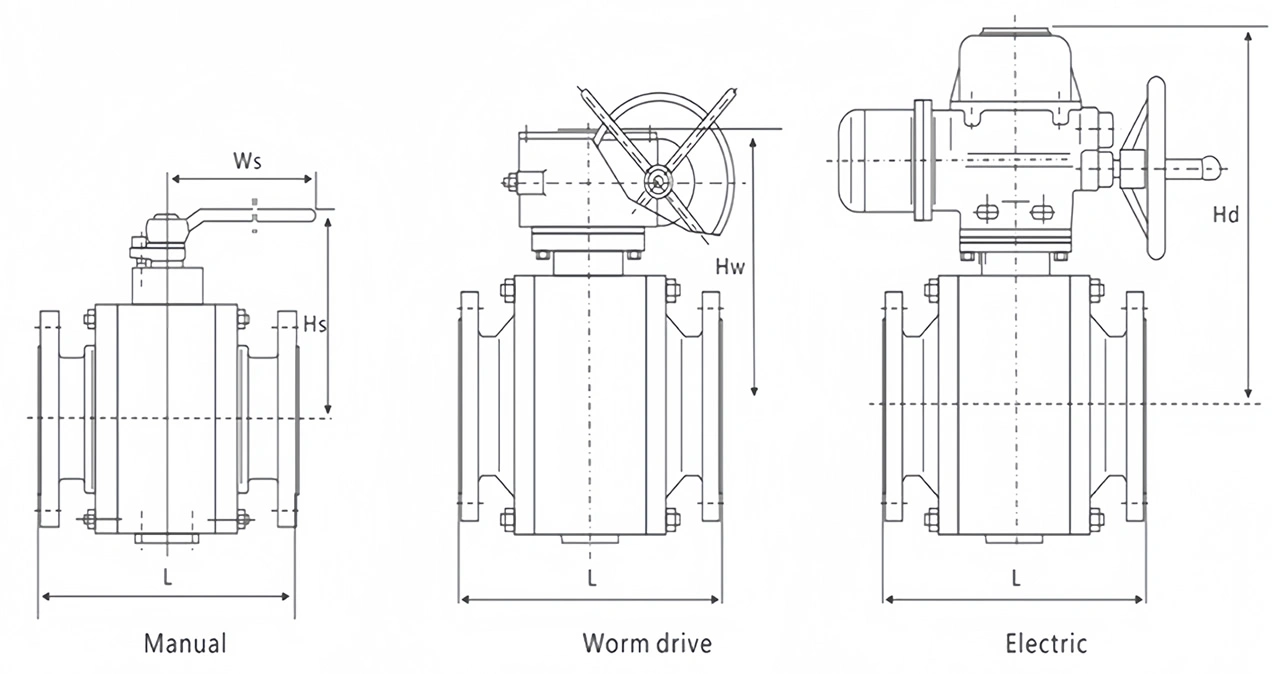

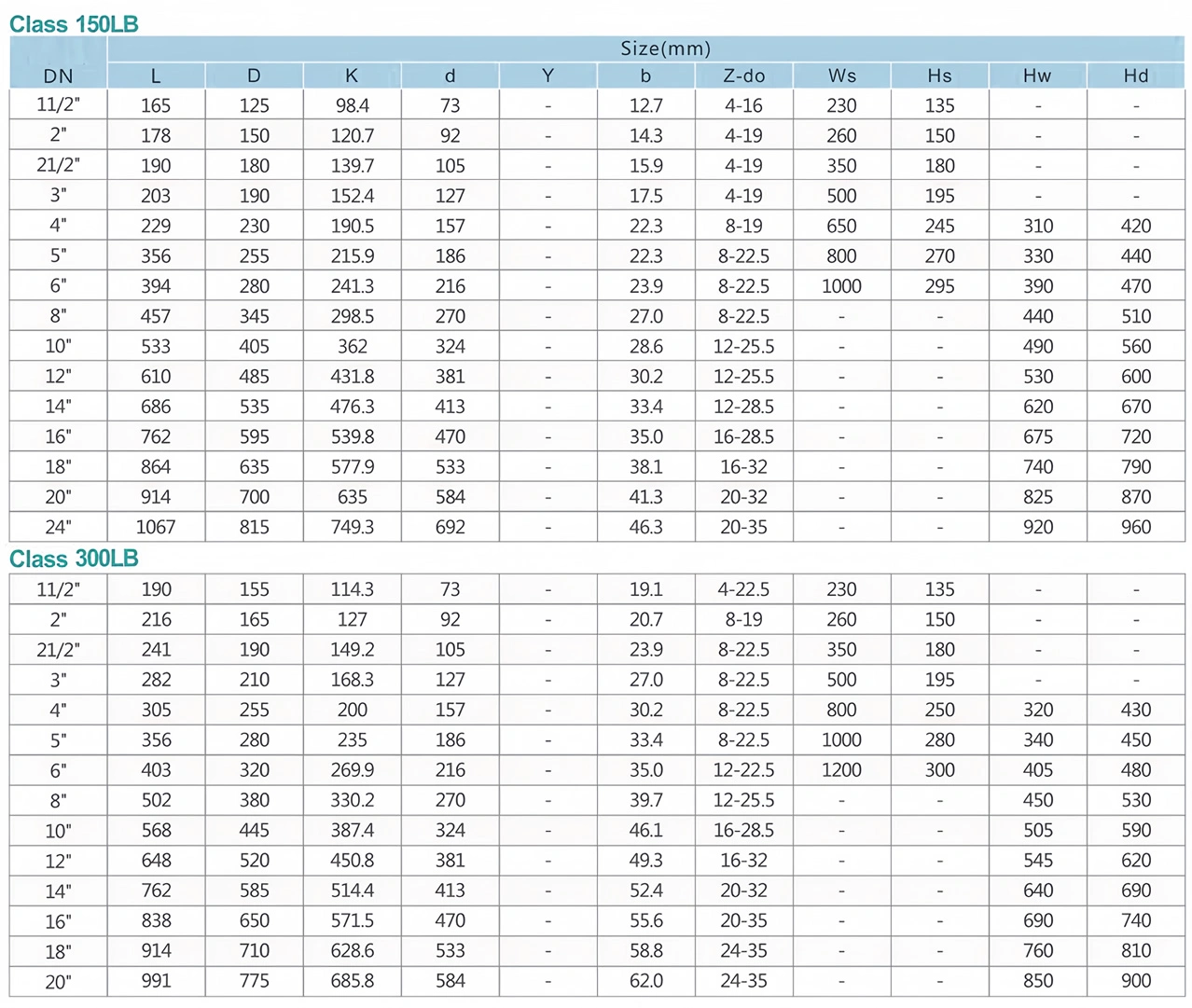

Rated for nominal diameters from DN15 to DN200 and pressure classes from PN10 to PN40 (Class 150 to 300), the valve operates reliably across temperatures from -29℃ to 425℃—covering ambient fluid transfer, high-temperature steam service, and low-temperature process applications. Available in manual, pneumatic, or electric actuation, it delivers flexible control options for diverse system requirements, from small-scale industrial pipelines to large-scale oil & gas transmission lines. As a trusted product from a leading manufacturer, it balances durability, compliance, and cost-effectiveness to minimize downtime and lifecycle costs for critical flow control systems.

Every component is selected to withstand harsh industrial conditions, with material compatibility tailored to pressure, temperature, and media requirements: