The full bore flow path is one of the core advantages of this valve. Compared to reduced-bore valves, its flow path diameter matches the pipeline, eliminating obvious “bottlenecks” during media flow and reducing local resistance loss by over 90%. For the DN50 specification, under the same media flow rate, its pressure loss is only 1/5 of that of reduced-bore valves, significantly reducing energy consumption of pump equipment. It is particularly suitable for long-distance transportation of oil and natural gas or large-flow water circulation systems (e.g., cooling water pipelines in thermal power plants).

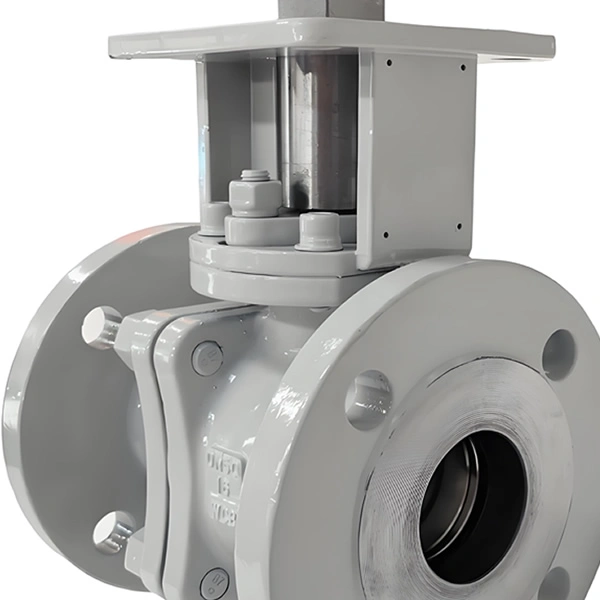

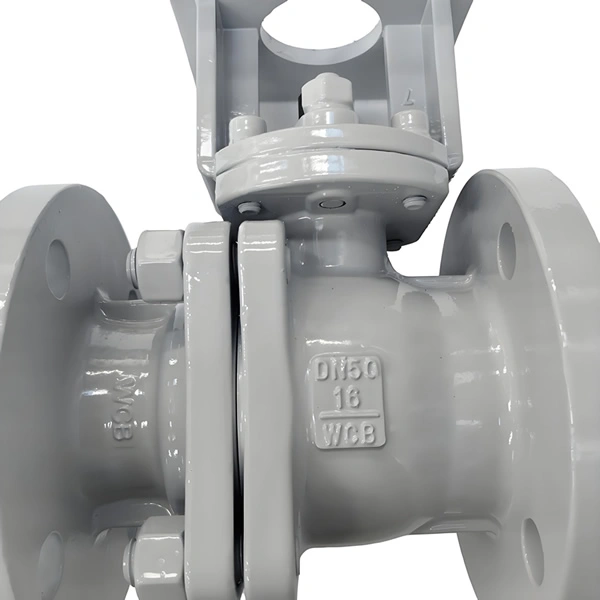

The combination of the floating ball design and diverse valve seat materials endows the valve with excellent sealing reliability. When the valve is closed, media pressure pushes the ball toward the outlet-side valve seat, forming a tight fit—the higher the pressure, the more significant the sealing effect. Even under the rated PN16 pressure, it can achieve “zero leakage.” The wall thickness design of the WCB cast steel valve body complies with ASME B16.34 standards, withstanding 1.5 times the nominal pressure (24bar for PN16) in shell tests without deformation or leakage, ensuring structural safety under high-pressure conditions.

Diverse operation modes enable adaptation to different scenarios: Manual operation (with locking) is suitable for small pipelines or systems requiring infrequent adjustment, with an operating force ≤30N (for DN50), allowing easy opening/closing by a single person; Worm gear transmission reduces operating force through a reduction mechanism, suitable for large-diameter valves (e.g., DN300 and above) or those under higher pressure; Pneumatic/electric actuators can be linked with PLC systems to 实现 remote switching or flow adjustment, with a response time ≤5 seconds, meeting control requirements of automated production lines.

The valve can work stably within a temperature range of -20℃ to 200℃, covering most industrial normal-temperature scenarios (e.g., urban water supply, lubricating oil pipelines). For high-temperature needs, metal-sealed valve seats can be selected, extending the temperature upper limit to 880℃ (with corresponding material matching). Additionally, the impact resistance and fatigue resistance of WCB cast steel allow it to adapt to pulsating media pressure (e.g., reciprocating pump outlet pipelines), with a service life of over 100,000 opening/closing cycles.

Raw materials for core components such as the valve body and ball undergo strict incoming inspection, including chemical composition analysis (spectral detection) and mechanical property testing (tensile and impact tests), with complete material certificates (e.g., melting number, heat treatment records) provided. WCB cast steel undergoes normalizing treatment (holding at 850-900℃ followed by air cooling) to eliminate casting internal stress, preventing deformation due to stress release after processing. The ball surface is precision-ground using a centerless grinder, with roughness controlled below Ra0.8μm to ensure fitting accuracy with the valve seat.

The two-piece valve body is precision-machined using CNC lathes and machining centers, with key dimensions (e.g., flatness of flange sealing faces, tolerances of valve seat installation grooves) controlled within ±0.02mm. The flange sealing face is processed into an RF (raised face) structure using a dedicated milling machine, with sealing waterline depth and spacing conforming to ASME B16.5 standards to ensure effective contact with gaskets. The valve body joint face is connected by a combination of positioning pins and bolts, ensuring that the coaxiality error of the flow path center after assembly is ≤0.1mm/m to avoid ball jamming.

- Shell pressure test: Clean water (or kerosene) is filled into the valve body, applying 1.5 times the nominal pressure (24bar for PN16), holding for 30 minutes. No leakage or structural deformation is confirmed through pressure decay method (allowable pressure drop ≤0.5bar/h) and visual inspection;

- Sealing performance test: 1.1 times the nominal pressure (17.6bar) is applied to the inlet and outlet sides respectively, holding for 15 minutes. Zero leakage is ensured using the bubble method (≤1 bubble per minute);

- Operational performance test: Under no-pressure conditions, the valve is manually/electrically operated to complete 5 full open-close cycles, recording operating force and stroke time to ensure no jamming, no loosening, and accurate limiting (full open/close position deviation ≤1°).

The valve body surface is sandblasted to Sa2.5 grade, then sprayed with two coats of high-performance epoxy anti-rust paint, with a dry film thickness ≥100μm. It passes a salt spray test for ≥500 hours, adapting to humid or outdoor environments. Packaging uses export-grade wooden cases, with the valve wrapped in EPE foam inside and protective covers added to both flanges to prevent scratches on sealing faces during transportation. Product specifications, pressure ratings, weight, and other information are marked on the case for easy storage and on-site acceptance.