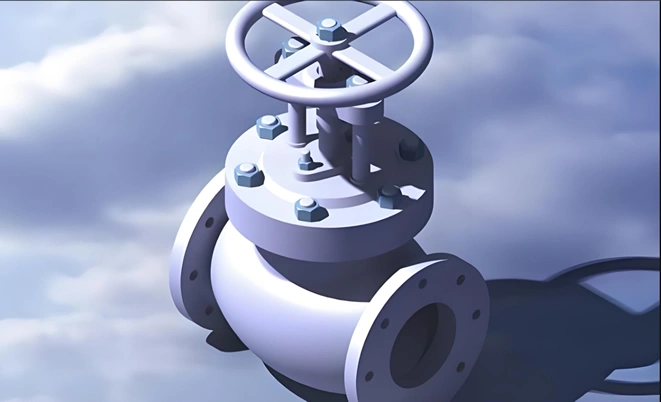

TIANYU API 6D DN300 CLASS300 trunnion mounted ball valve is a premium fluid control solution engineered for critical oil and gas, petrochemical, and industrial applications, blending CF8/CF8M stainless steel corrosion resistance with NACE MR0175 sour service compliance and API 6D pipeline valve standards. Its trunnion mounted design delivers unrivaled bi-directional sealing and low operating torque