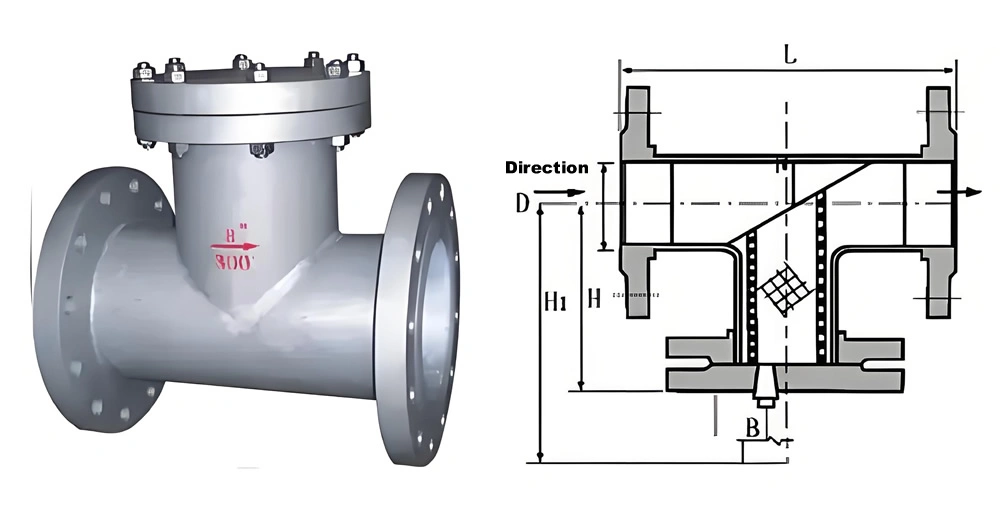

TIANYU Steel Fabricated T-Type Strainer (DN15-DN1000, 150lb-900lb) with butt-welded ends suits water, oil, steam. Features 304 screen, low pressure loss, easy maintenance. Applies to petrochemical, power, municipal fields. Customizable in material and screen mesh for specific needs.