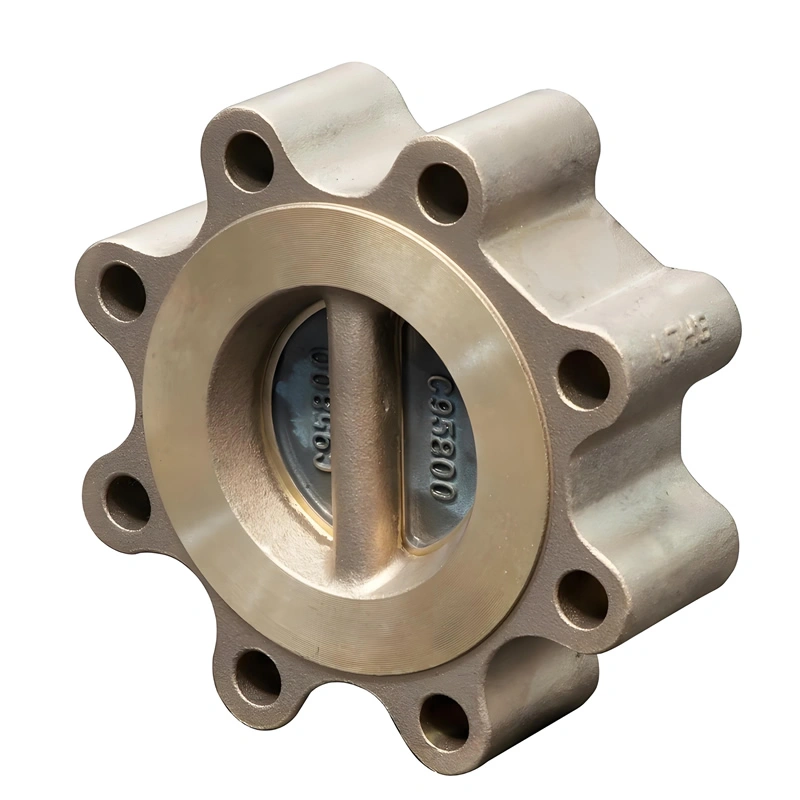

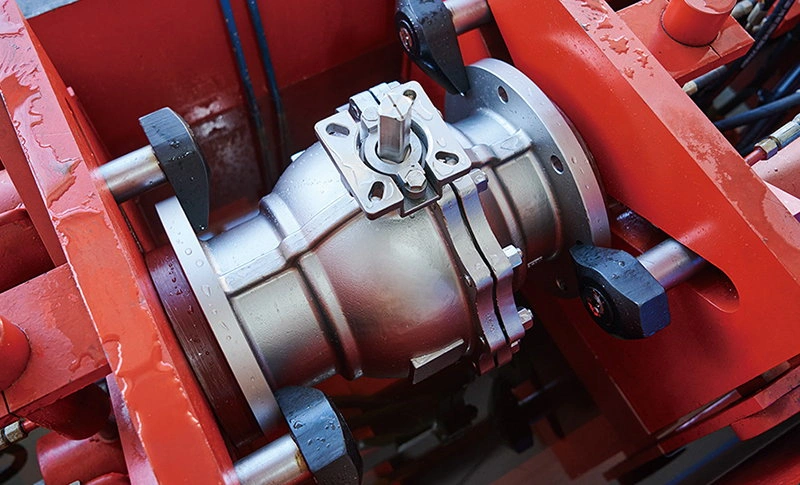

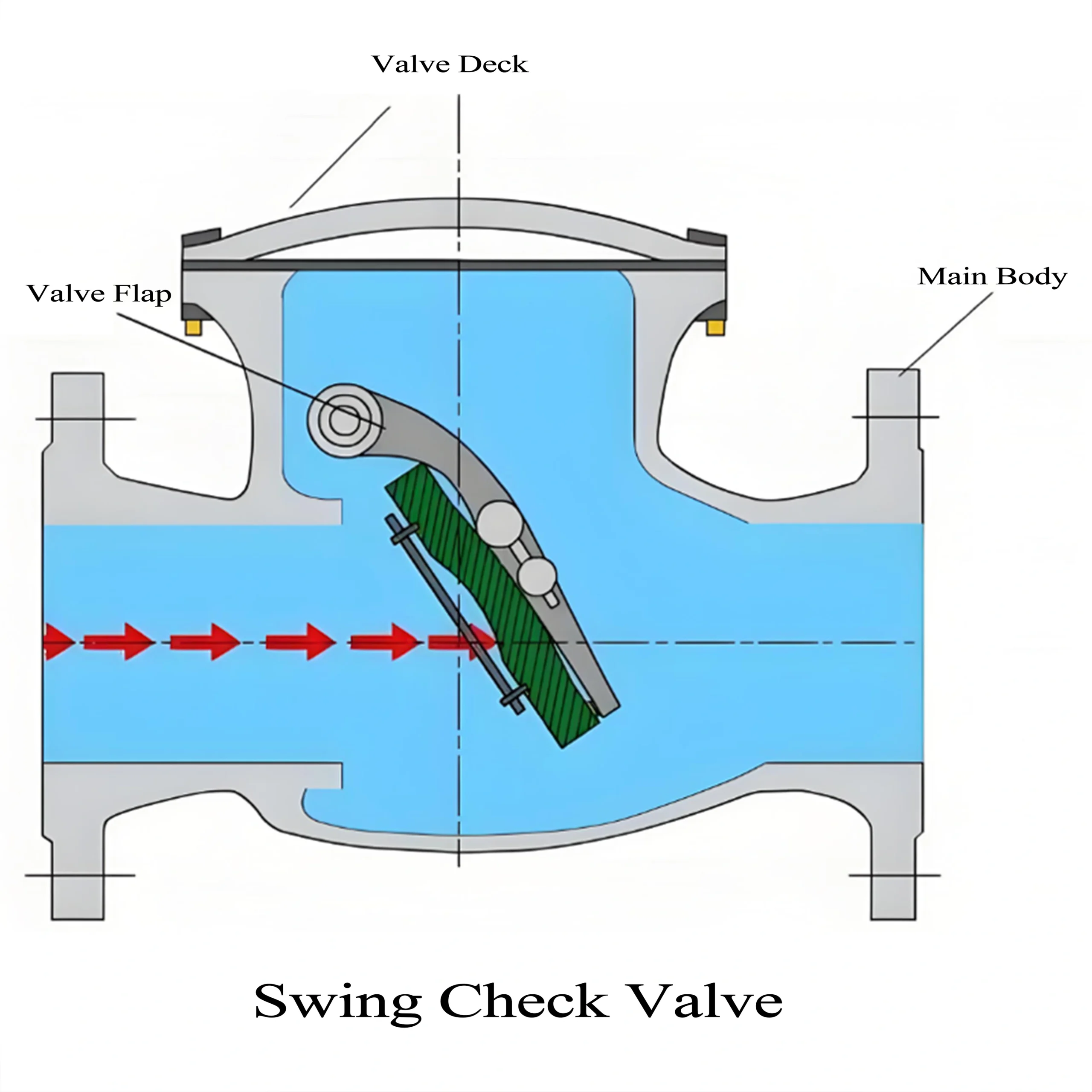

DN15-DN200, PN16-PN40 Stainless Steel Energy Saving Silenced Flanged Check Valve for Drainage Pipes Well Sealed and Durable ensures reliable non-return flow for water, oil, gas. It features corrosion resistance, energy-saving low pressure drop, rapid water hammer prevention, and dual-seal options (metal/PTFE). Compliant with GB/T 12235, API 598, it suits water treatment, oil/gas, and chemical sectors. Customizable in seal type, flange standard, and anti-static/fire-safe features to meet specific application needs.