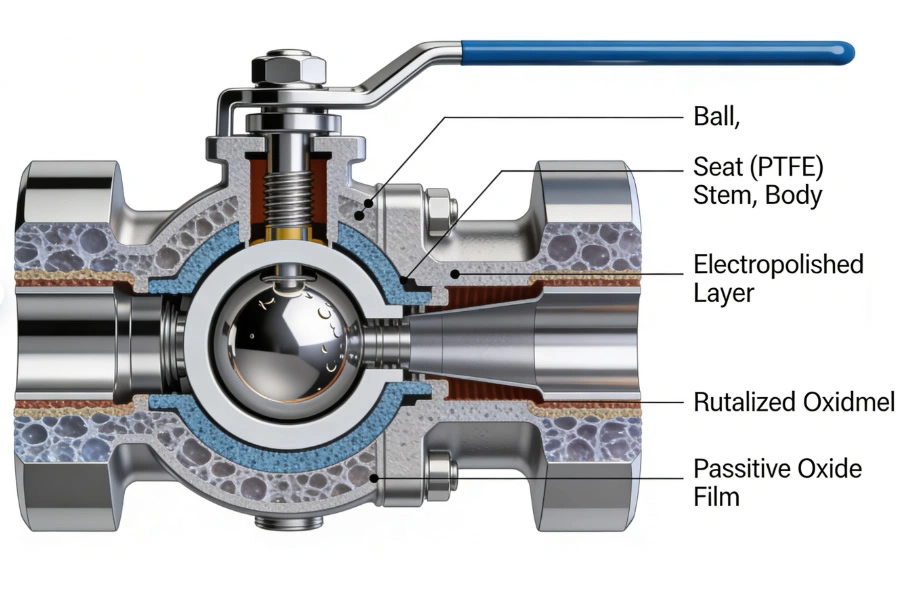

The sealing element is vital for valves, preventing media leakage when closed. Made of durable, corrosion-resistant materials, it withstands pressure, temperature, and corrosion. Its repeated friction during operation makes material choice and manufacturing quality crucial for sealing performance and valve lifespan, regardless of valve type.

Flanged Carbon Steel T-type Strainer, with DN25-DN1000, 10K/20K pressure classes, and 220-350℃ temperature range, suits water, oil, steam. It features basket screen, quick-open cover, low pressure loss, and reliable sealing, applied in petrochemical, power, municipal fields. Customizable in screen mesh and material for specific needs.