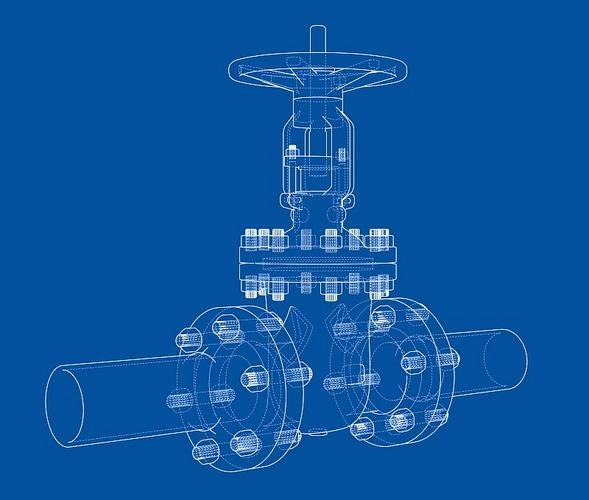

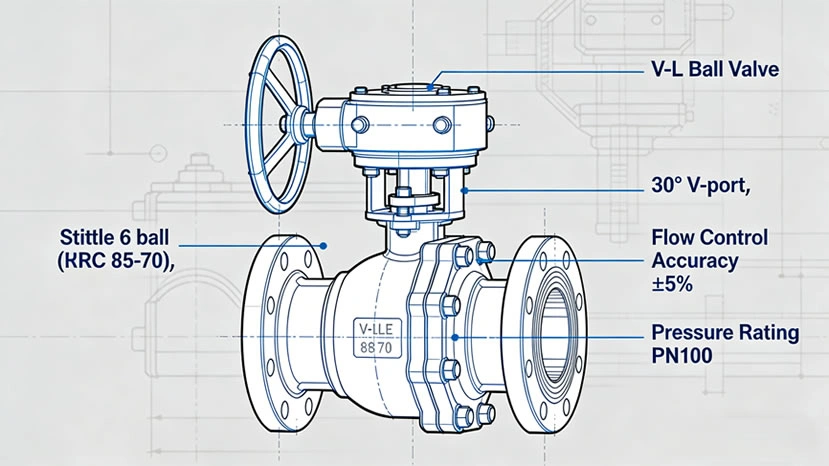

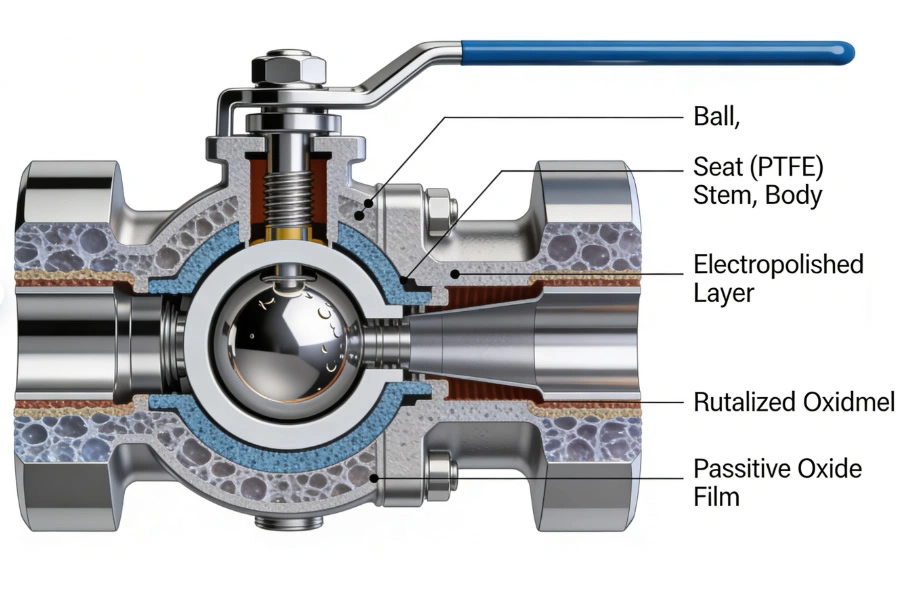

TIANYU zero-leakage direct-buried flat plate gate valves address underground pipeline challenges with anti-settlement structure, three-layer anti-corrosion, and bidirectional sealing. Covering DN50-DN1200, they suit water, gas, and heating buried control, supporting deep customization—ideal for modern urban underground network construction.