The sealing element is vital for valves, preventing media leakage when closed. Made of durable, corrosion-resistant materials, it withstands pressure, temperature, and corrosion. Its repeated friction during operation makes material choice and manufacturing quality crucial for sealing performance and valve lifespan, regardless of valve type.

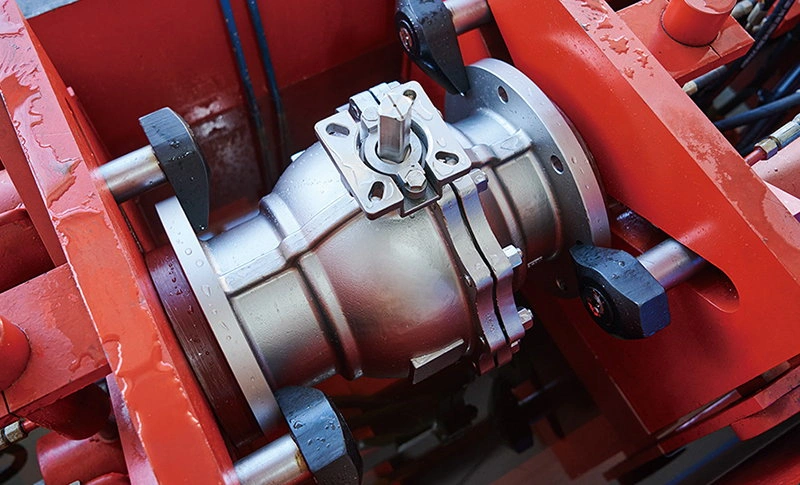

ASME Pressure Balanced Inverted Hard Seal Manual Plug Valve for General Industrial Water and Fluid Control Applications TIANYU American standard pressure balanced inverted hard seal manual plug valve, sized 1/4in-2-1/2in, excels in low/medium/high-pressure systems. Its inverted design ensures lightweight operation, hard seal guarantees leak resistance, and it handles water and general fluids across temperatures.it suits water management and industrial pipelines. Customization (sizes, materials) is available to meet specific needs.