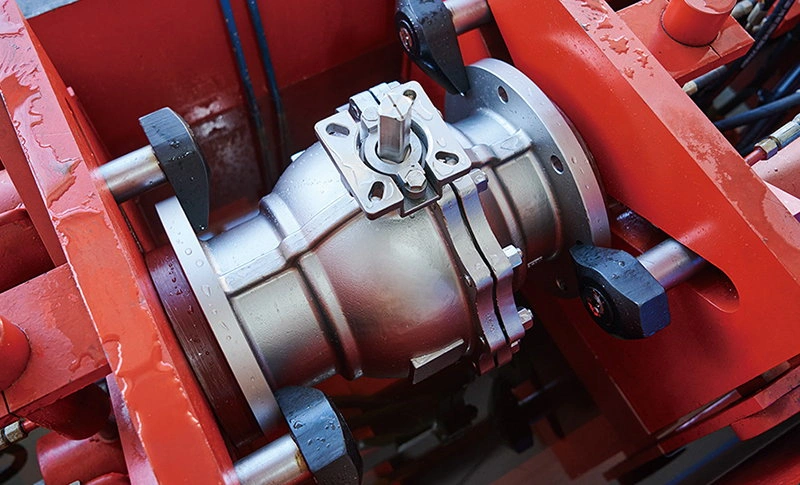

The Globe Valves Manufacturer provided by Tianyu mainly include straight pattern globe valve, Y pattern globe valve, both bolted bonnet and pressure seal bonnet type are available , which are designed and manufactured according to DIN and ASME, The globe valve is suitable for several media including water, steam, oil, gas, petrol products, nitric acid, acetic acid, etc.

The globe valve, also called stop valve, relies on the pressure of the stem, making the sealing surface between disc and seat closely fitted to prevent the circulation of the medium. As the short opening and closing stroke of stem, globe valve has a reliable cut-off function. Due to the change of the valve seat opening is proportional to the stroke of the valve flap, it is suitable for the flow regulation and frequent operation.

Design features:

Disc: Single disc by defaultand double disc is applied for larger pressure difference or bigger size, the flow diretcion can be from lower inlet to higher out let, and from higher inlet to lower outlet is normally used for refinery to ensure the protetc stem seal from leakage.

Flat disc, conical disc, and plug loose type disc can be made upon request.

Seat: Welded seat and integral seat.

Body – Bonnet Connetcion: Bolted bonnet (BB) is normally applied on CL150 – CL900, body bonnet seal is defaulted by gasket and RTJ ring. Pressure seal bonnet (PSB) is applied on CL1500 – CL2500 with pressure seal ring for body bonnet seal.

Packing: By default graphite packing is used, PTFE packing can be used on corrosive media. API 622 fugitive emission packing will be used upon request.

Back seat: Renewable back seat is applied on carbon steel and low alloy steel valve, body back seat is applied for stainless steel valve.

Actuation: Hand wheel and gear box are normally designed for cast gate valve based on different size and pressure rating; Eletcric, pneumatic or Chain wheel operation can be provided upon request.

Product Range:

Size: 2 Inch – 24 Inch (DN50 – DN600).

Pressure Rating: Class 150 LB – 2500 LB (PN16 – PN420).

Material: Carbon steel, Stainless steel, Alloy steel, including WCB, GS-C25, LCB, LCC, LC1, LC3, CF8, CF8M, CF3, CF3M, WC6, C5, C9, C12, 4A, 5A, MONEL, ALLOY20, C95800

Connetcion End: BW, RTJ, Flanged.

Operation: Handwheel, Gearbox, Eletcric, Pneumatic.

Design & Manufacture Standard: ASME B16.34, BS 1873, DIN 3356, Bolted bonnet, pressure bonnet, bellow seal bonnet, high/low temperature extended bonnet and ISO 15848 fugitive emission designed valves are available upon different request of services.

Test Standard: API 598, EN 12266.