The sealing element is vital for valves, preventing media leakage when closed. Made of durable, corrosion-resistant materials, it withstands pressure, temperature, and corrosion. Its repeated friction during operation makes material choice and manufacturing quality crucial for sealing performance and valve lifespan, regardless of valve type.

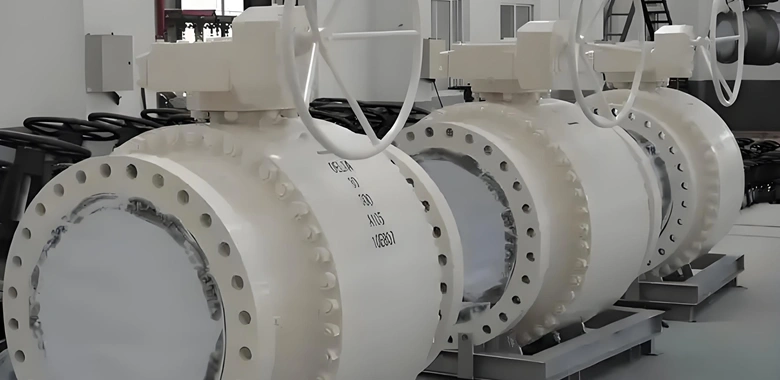

TIANYU DN100 PN16 CF8 Electric Actuator Motorized Ball Valve delivers automated precision, CF8 corrosion resistance, full-port efficiency, and ANSI Class VI sealing. Compliant with API 6D/ASME standards, it serves chemical, energy, water, and petrochemical sectors reliably.Customize with 316L stainless steel for harsh corrosion, extended temperature (-40℃~250℃) with metal seals, explosion-proof actuator (ATEX), 4-20mA modulating control, or flange standards (GOST, JIS). Tailor to your media, pressure, and automation needs.