The sealing element is vital for valves, preventing media leakage when closed. Made of durable, corrosion-resistant materials, it withstands pressure, temperature, and corrosion. Its repeated friction during operation makes material choice and manufacturing quality crucial for sealing performance and valve lifespan, regardless of valve type.

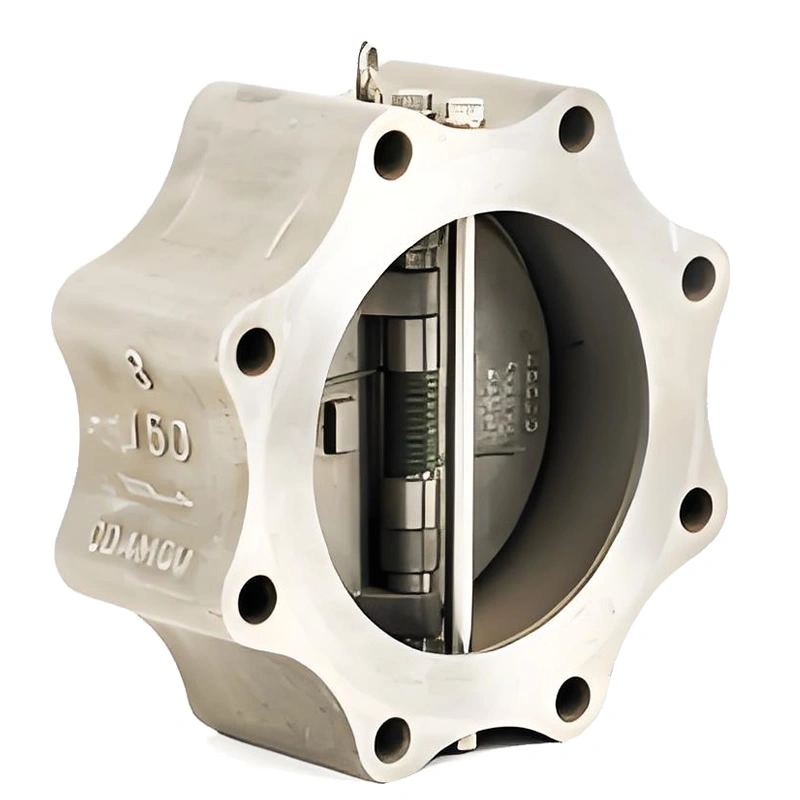

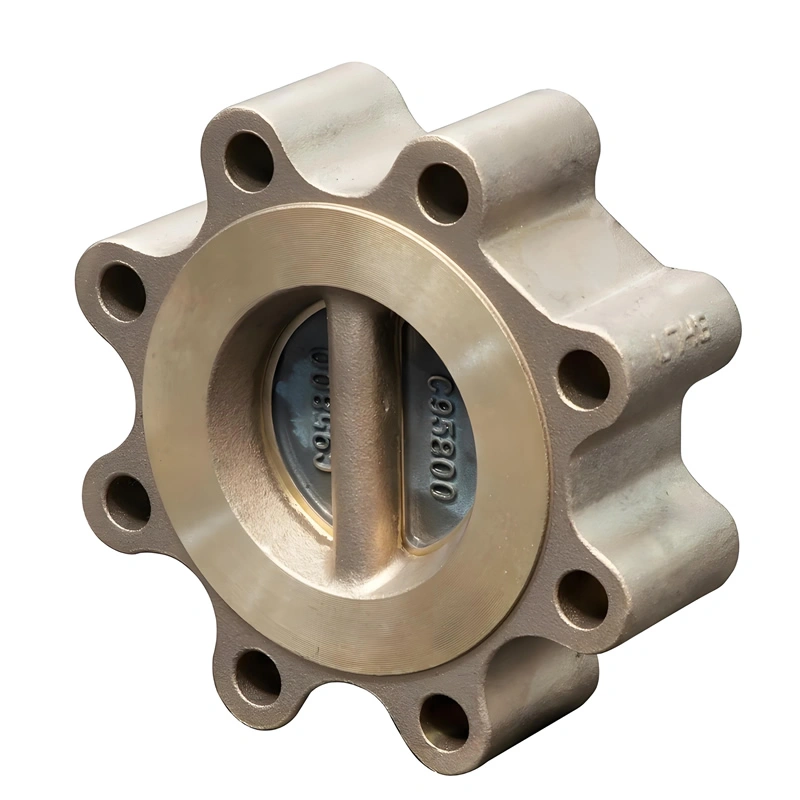

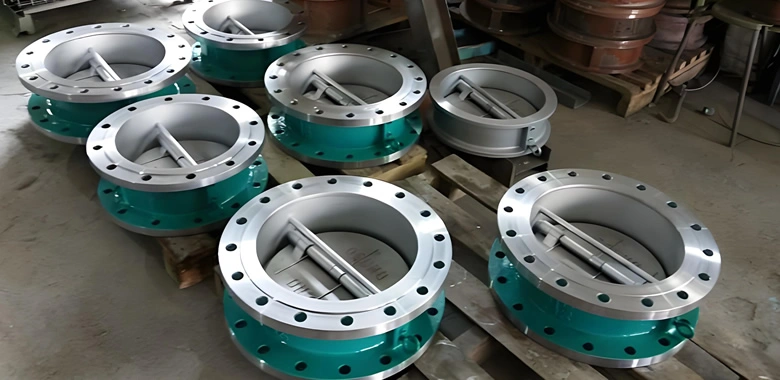

TIANYU 4” Class 300 A105 dual-disc wafer check valve delivers low flow resistance, rapid closure, and hard-seal reliability for industrial medium-to-high pressure applications. Compliant with API/ASME standards, it combines A105 durability, dual-disc efficiency, and wafer connection convenience—ideal for oil, gas, chemical, and power sectors.Customize with 304/316 stainless steel for corrosion resistance, Stellite 21/Inconel for extreme wear/corrosion, pressure ratings (150LB–600LB), or flanged/butt-weld connections. Tailor to your media (corrosive/abrasive), temperature, and installation needs for optimal performance.