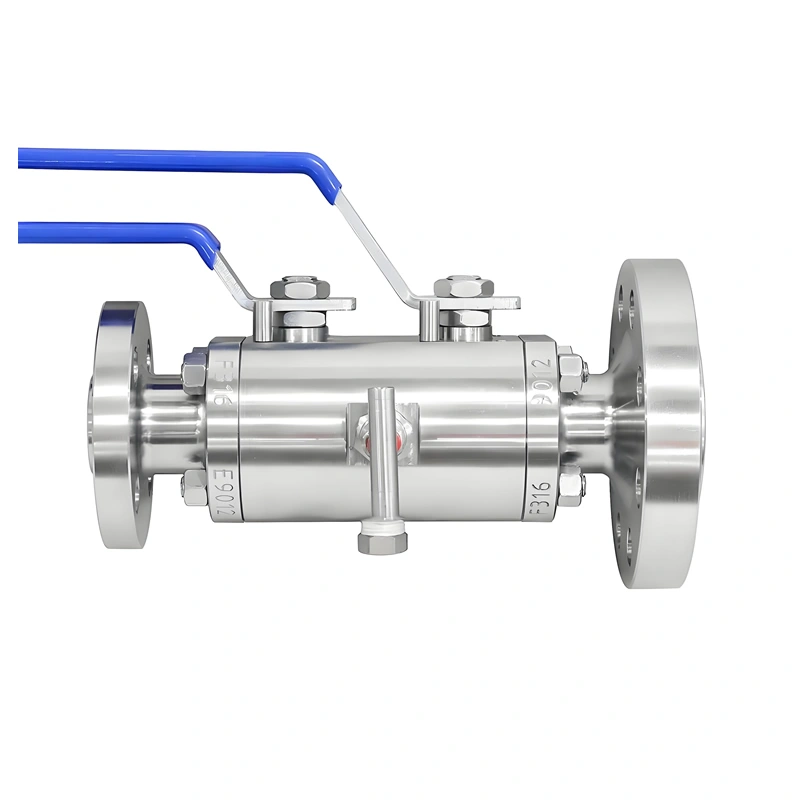

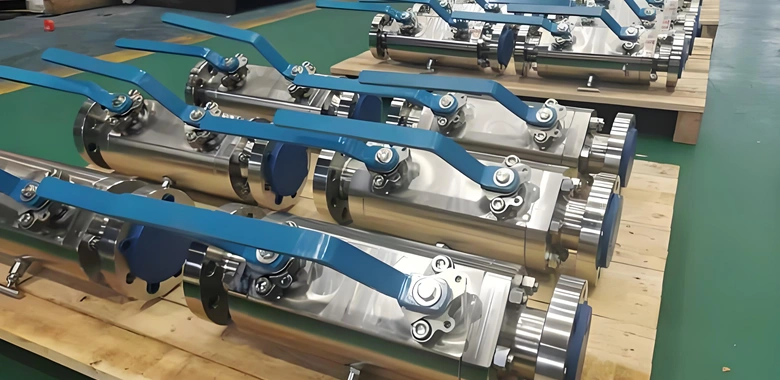

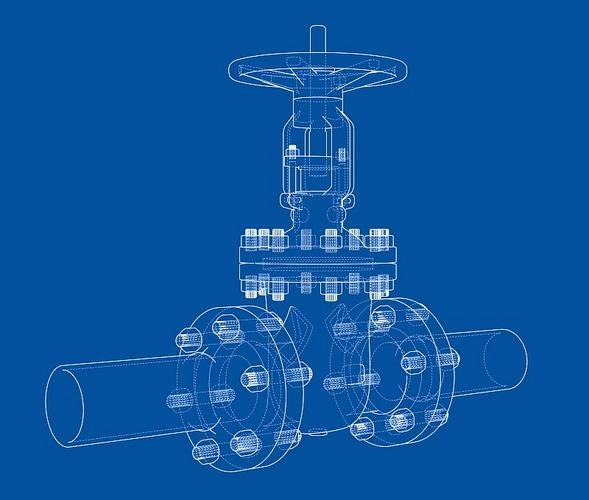

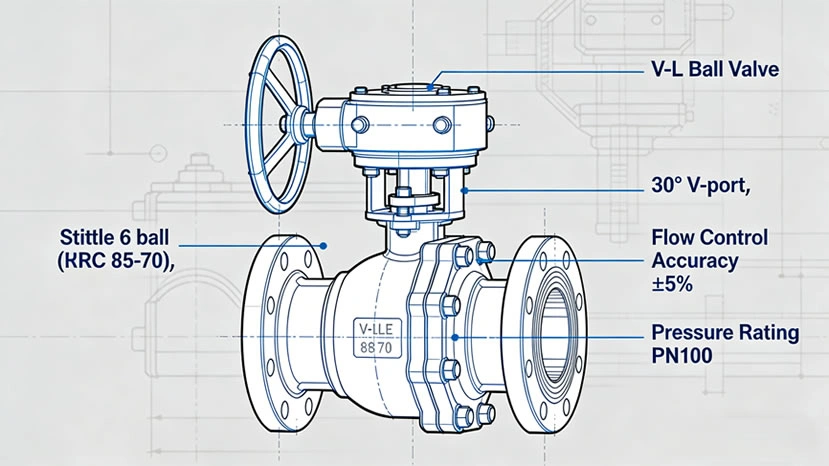

The TIANYU DN50 300LB DBB double block and bleed ball valve delivers uncompromising safety and reliability for critical fluid isolation applications, combining F316 stainless steel’s corrosion resistance with PEEK’s bubble-tight sealing performance. Its DBB design eliminates the need for multiple valves, reducing system complexity and leak points, while the fire-safe construction enhances protection in high-risk environments. Certified to API, ASME, and CE standards, and backed by ISO 9001 quality assurance, it excels in oil and gas, chemical processing, and pharmaceutical industries, ensuring efficient maintenance, regulatory compliance, and long-term operational value.