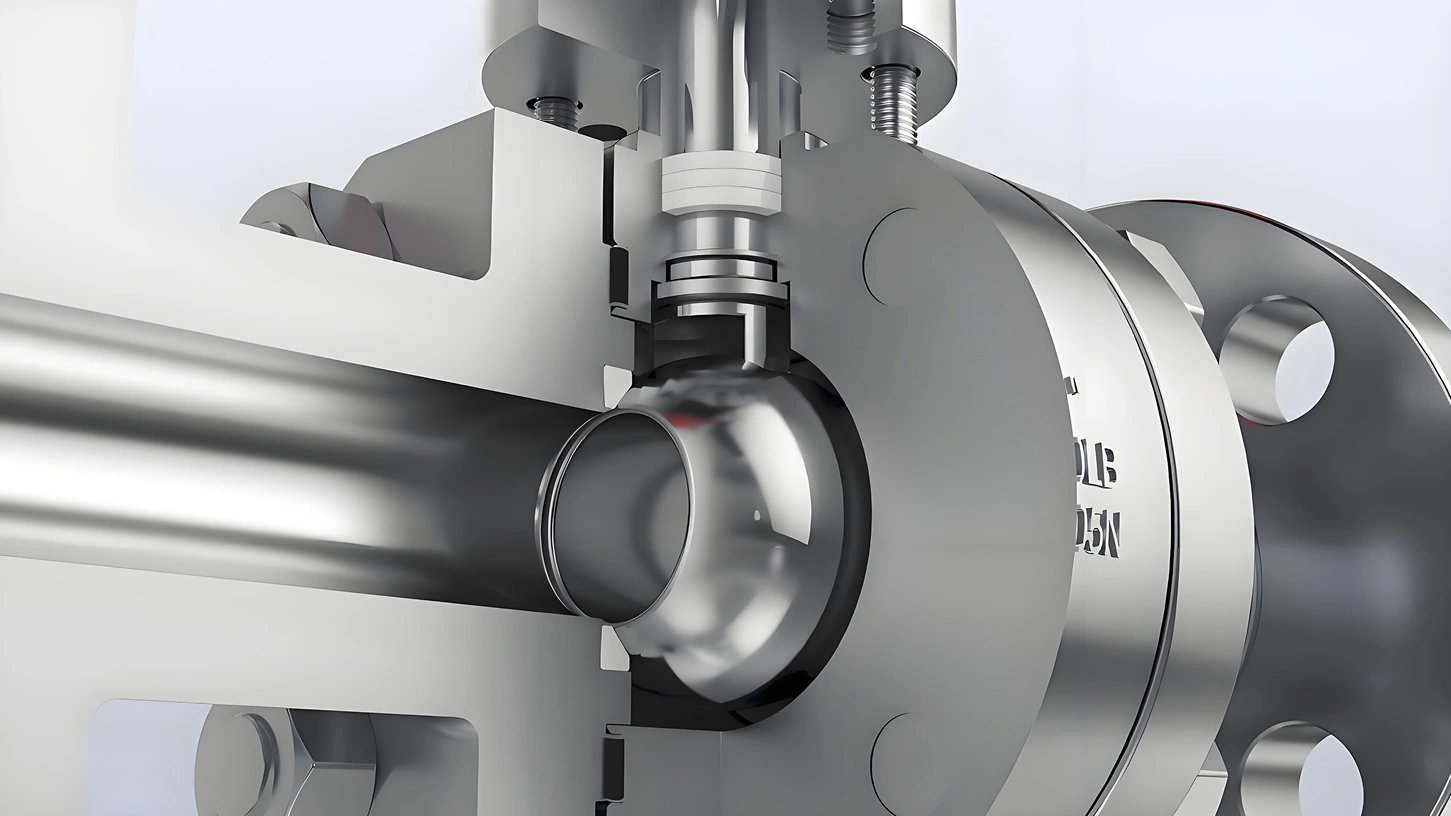

The sealing element is vital for valves, preventing media leakage when closed. Made of durable, corrosion-resistant materials, it withstands pressure, temperature, and corrosion. Its repeated friction during operation makes material choice and manufacturing quality crucial for sealing performance and valve lifespan, regardless of valve type.

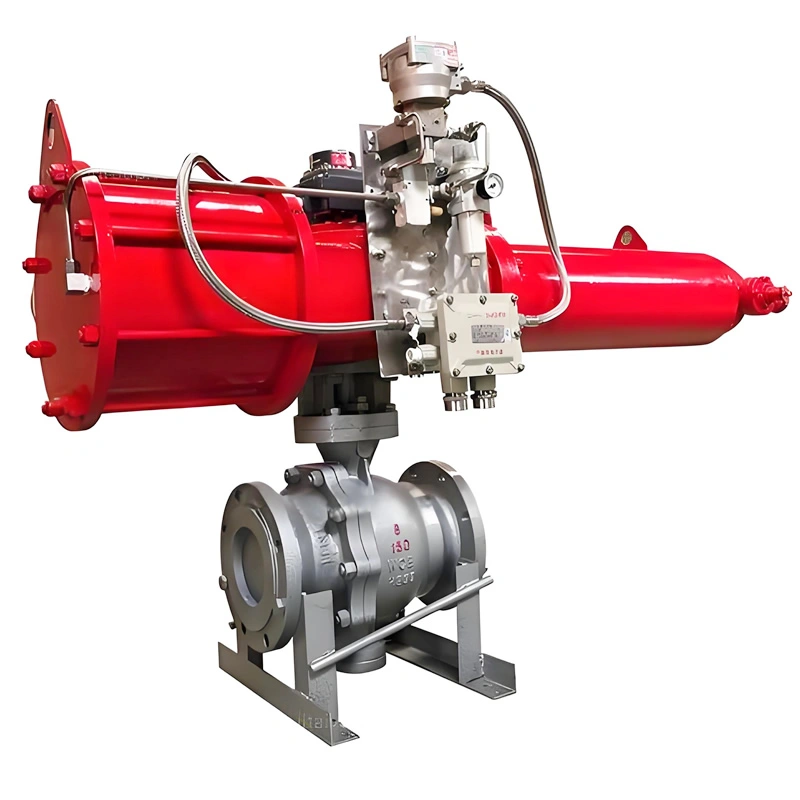

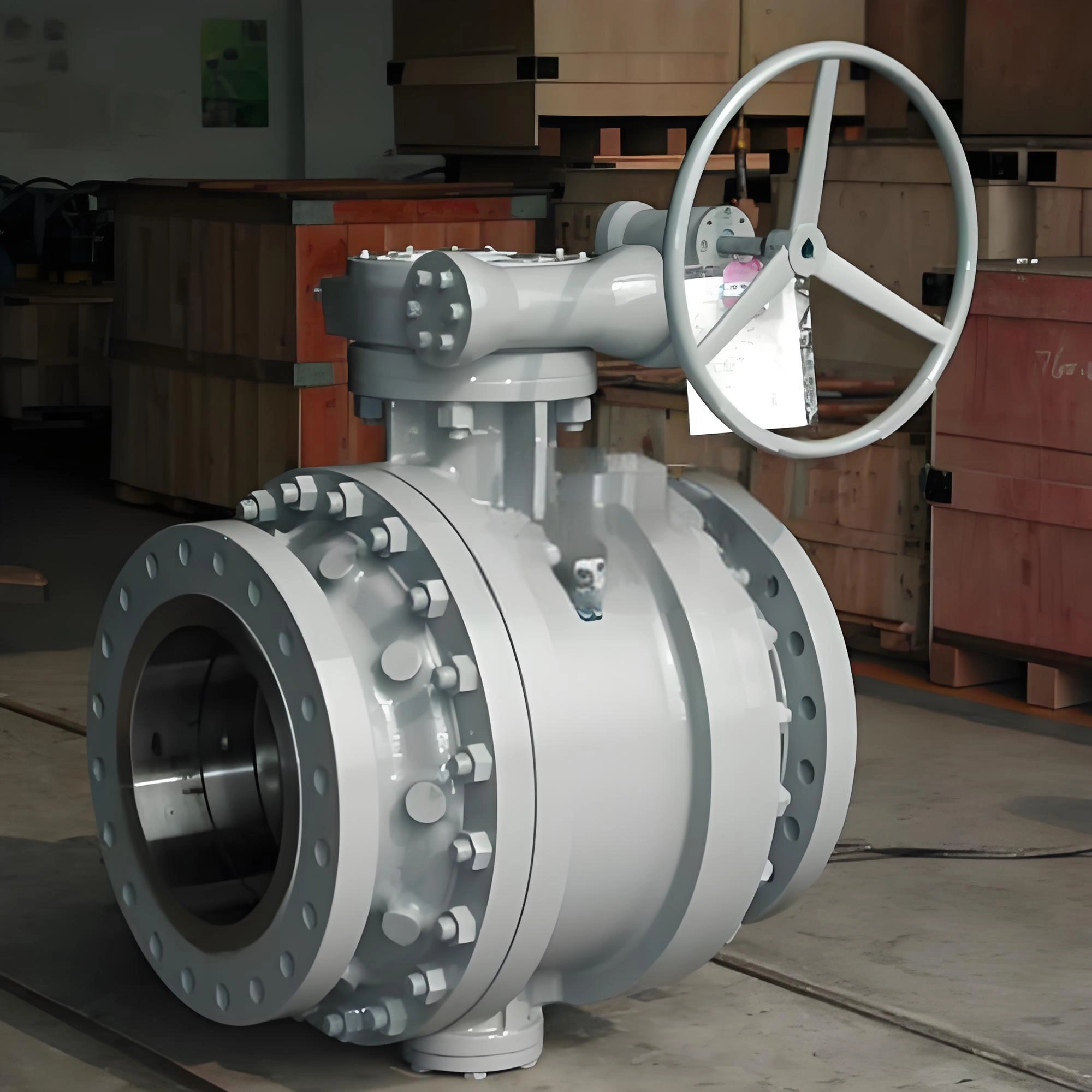

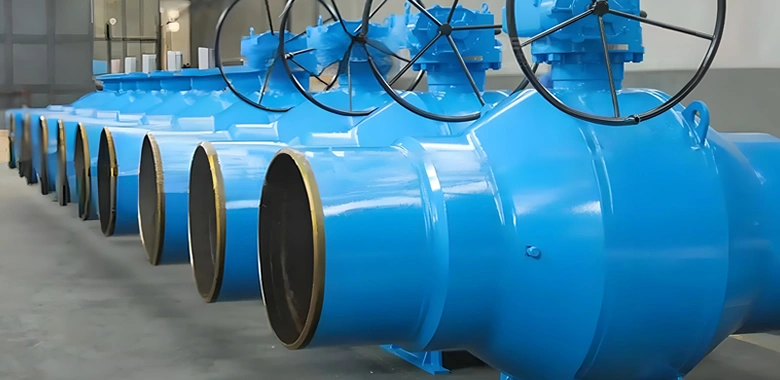

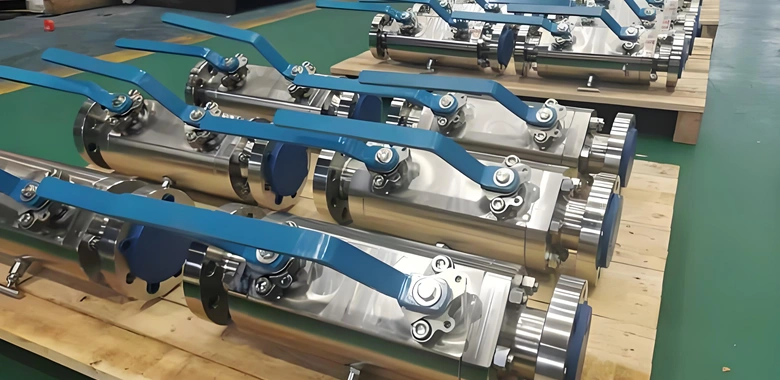

Customize this TIANYU valve to your operational needs: opt for 2205 duplex steel for extreme offshore corrosion, Inconel alloy for high-temperature (500℃+) service, or titanium for chemical resistance. Upgrade to 2500LB pressure for ultra-high-duty wellheads, select Viton seals for oil-rich media, or add ATEX/IECEx certification for explosive zones. Integrate smart electric actuators with IoT connectivity for remote monitoring, or choose reduced-port design for space constraints. These tweaks optimize performance, extend service life, and cut long-term costs—delivering a valve tailored to your unique workflow.