I. Introduction: The Critical Role of V-Port Ball Valves in Mining Slurry Operations

Mining operations—from copper and iron ore extraction to coal and mineral processing—rely heavily on slurry systems to transport abrasive, high-density mixtures of solids and liquids. These slurries, composed of crushed ore, water, and often corrosive chemicals (e.g., flotation reagents, leaching acids), present unique challenges: extreme abrasion from 0.1–5 mm solid particles, high pressure (up to 100 bar), variable viscosity (100–10,000 cP), and clogging/valve seizure risks. A single valve failure can cause costly downtime—$25,000 to $150,000 per hour—plus increased maintenance, equipment damage, and production losses.

Traditional valves (gate, globe, standard full-port ball) struggle in these environments: gate valves need replacement every 3–6 months due to seat wear and clogging; globe valves have high pressure drop and poor abrasion resistance; standard ball valves lack precise flow control for slurry velocity regulation. V-port ball valves, by contrast, combine precision flow modulation (±1% accuracy), exceptional wear resistance, and anti-clogging design, delivering 2–5 years of service life in most mining applications.

The V-port’s contoured design enables both on/off isolation and proportional flow control. As the ball rotates 90°, the V-port gradually opens/closes to adjust flow rate, while its streamlined profile minimizes turbulence and particle accumulation. Fully open, it reduces pressure drop and pump energy consumption. With the global mining valve market projected to reach $7.3 billion by 2030 (CAGR 5.4%), understanding V-port valves is critical for optimizing efficiency and reducing costs. This article analyzes their design, performance, applications, and maintenance, concluding with TIANYU’s custom advantages.

II. Core Design Principles of V-Port Ball Valves for Mining Slurry Systems

V-port ball valves balance three key goals: precision flow control, wear resistance, and anti-clogging performance. Every component is optimized for slurry transport, differing from standard ball valves designed primarily for on/off service.

II.A. V-Port Design: Precision and Anti-Clogging

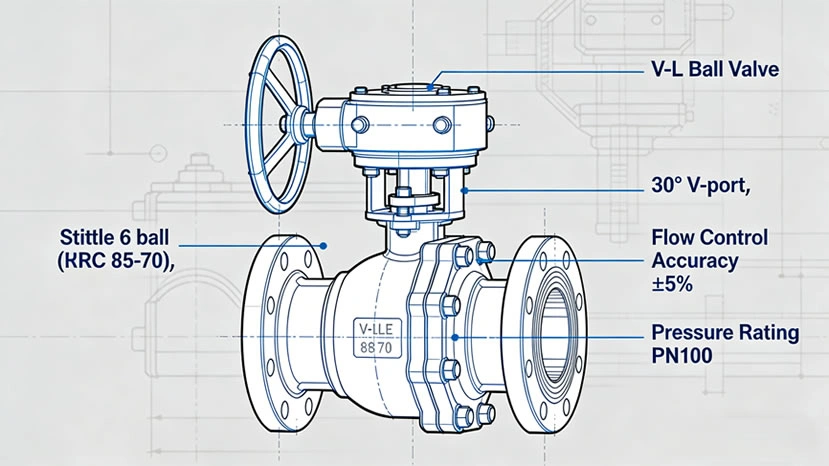

The V-port—machined at 15°–90° angles—determines flow characteristics (linear, equal percentage, quick-opening). Linear flow (30°–45° ports) is most common, enabling precise adjustment of slurry velocity to 2–4 m/s (critical to prevent sedimentation below 2 m/s and 300% increased erosion above 4 m/s). A 30° V-port DN150 valve at 50 bar modulates flow 0–200 m³/h with ±1% accuracy.

Its streamlined design minimizes dead zones and turbulence, while tapered edges create a scouring effect to sweep solids and prevent seizure—unlike flat full-port valves that trap ≥1 mm particles. Precision-ground to Ra ≤ 1.6 μm, the port reduces friction and wear. Port diameter (50–80% of DN) matches particle size: 70–80% for 2–5 mm solids, 50–60% for 0.1–1 mm fines. A DN200 70% port (140 mm) handles 4 mm particles with a Cv of 150, cutting pressure drop 25% vs. standard globe valves.

II.B. Valve Body and Ball Construction: Wear Resistance

Valve bodies use ductile iron (ASTM A536 Grade 65-45-12) or carbon steel (ASTM A216 WCB) for standard slurries (450–600 MPa tensile strength), 316L stainless steel/duplex 2205 for corrosive acid leaching. Internal flow paths (Ra ≤ 3.2 μm) have 15–20% thicker walls at critical wear points to resist particle impact.

Balls—critical wear components—use Stellite 6 (HRC 65–70, ≤0.002 mm/year wear in 50% solids), tungsten carbide (HRC 85–90, ≤0.001 mm/year in 70% solids), or ceramic (HRC 90+). CNC-machined to ±0.02 mm tolerances, many have 50–100 μm hard chrome/ceramic coatings (30% wear reduction for chrome, 50–100% for ceramic). Solid one-piece construction prevents internal corrosion and ensures high-pressure integrity.

II.C. Seat Design: Seal Tightness and Wear

Spring-loaded floating seats maintain ANSI Class IV/V shutoff (≤0.01%/≤0.001% full flow leakage). For DN150 valves at 50 bar, this equals ≤0.02 GPM (Class IV) or ≤0.002 GPM (Class V)—critical for environmental safety. Seat materials: – Polyurethane (PU): 90–95 A Shore hardness, 1–2 year service for 30–50% solids, low chemical aggressiveness. – Ceramic: HRC 85+, 2–3 year service for 50–70% solids/large particles (brittle, careful handling required). – PTFE with 15–20% carbon: Chemically inert, 1–1.5 year service for corrosive slurries.

Purge ports flush seat areas with clean water/compressed air, extending seat life 30–40% in high-solids slurries by removing accumulated solids.

II.D. Stem and Actuation Design: Reliability

Stems use 17-4 PH stainless steel (HRC 35–40) or Inconel 718 (860–1,100 MPa tensile strength), precision-ground to Ra ≤ 0.8 μm with multi-layer graphite/PTFE-Inconel packing (20–30 N·m torque for DN150, zero leakage at 100 bar/150°C).

Actuators: Manual (handwheel + 10:1 gearbox, 80 N force for DN100) for low-cycle (≤10/day) small valves; automated (pneumatic/electric) for high-cycle (≥10/day) large valves. Pneumatic (70% of installations) uses 4–8 bar air, 0.3–0.5s 90° rotation, spring-return fail-safe; DN200 models deliver 500–800 N·m at 6 bar. Electric (±0.5% accuracy) uses 110V/220V/380V AC motors, 0.75 kW DN250 models consume 0.75–1.0 kWh/h, 5–7 year service life.

III. Performance Metrics: Data-Driven Validation

V-port valves outperform traditional types across key metrics critical to mining slurries, validated by real-world and laboratory data.

III.A. Flow Control Precision and Turbulence Reduction

With ±1% control accuracy (vs. ±5% gate, ±3% globe), V-port valves maintain 2–4 m/s slurry velocity. Tests on DN150 30° V-port valves (Stellite/PU) in 50% solids copper slurry (0.5–2 mm, 500 cP): 25% rotation = 50 m³/h (2.1 m/s), 50% = 100 m³/h (3.0 m/s), 75% = 150 m³/h (3.9 m/s), 100% = 200 m³/h (4.2 m/s). Streamlined design cuts turbulence 40–50%, extending pipe/valve life 25%/20%.

III.B. Abrasion Resistance and Service Life

Service life is 3–5x longer than gate valves, 2–3x longer than globe valves: – Copper Mining: DN200 (Stellite/ceramic) in 40% solids flotation circuits: 3.5 years (vs. 0.8 gate, 1.5 globe). – Iron Mining: DN250 (tungsten carbide/ceramic) in 70% solids tailings: 2.8 years (vs. 0.6 gate, 1.2 globe). – Coal Mining: DN150 (duplex 2205/Stellite/PTFE) in 50% solids/10% H₂SO₄: 2.2 years (vs. 0.5 carbon steel gate).

ISO 15370 tests: Ceramic-coated Stellite ball wear = 0.0008 mm/year (15x less than standard carbon steel); PU seat wear = 0.003 mm/year (7x less than standard rubber).

III.C. Pressure Drop and Energy Efficiency

DN200 full-open tests (200 m³/h, 500 cP): V-port = 0.3 bar (vs. 1.2 globe, 0.5 gate). Annual savings: 15,000 kWh/valve vs. globe ($1,800 at $0.12/kWh); 100 valves save $180,000. Pressure drop remains consistent (no solids accumulation), unlike gate valves (50–100% drop over service life).

III.D. Leak Tightness and Environmental Safety

ANSI Class IV/V leak tightness (vs. Class II/III gate, Class IV globe). DN150 50 bar water tests: V-port Class V = ≤0.002 GPM (0.0001% full flow), globe Class IV = ≤0.02 GPM, gate Class III = ≤0.2 GPM. Spring-loaded seats maintain Class V tightness for 3 years; gate valves need seat replacement every 6 months.

III.E. Anti-Clogging Performance

DN200 70% port valves in 70% solids iron ore slurry (4 mm) run 1,000 hours clog-free (vs. 200 hours gate, 350 hours globe—each requiring 4-hour $1,000 cleaning). 10–15 L/min purge flushing (5 min/8 hours) reduces particle accumulation 80%, extending service life 30%.

IV. Industry-Specific Applications

V-port valves excel across mining sectors, addressing unique slurry challenges with proven performance gains.

IV.A. Copper Mining: Flotation and Acid Leaching

Chilean copper mine installed 120 DN200 duplex 2205/Stellite/PTFE V-port valves in flotation circuits: service life 3.5x longer (costs down 77% to $55,000/year), flow precision up to ±1% (2% copper recovery increase = 2,000 tons/$12M), downtime down 87.5% (5 hours/year vs. 40). Arizona mine used DN150 Hastelloy valves in 5–15% H₂SO₄ leaching: 90% fewer corrosion failures, 4.4x longer service life (2.2 vs. 0.5 years).

IV.B. Iron Mining: Ore Transport and Tailings

Brazilian iron mine installed 80 DN250 tungsten carbide/ceramic V-port valves in ore transport: 4.7x longer service life (2.8 vs. 0.6 years), 30% less pipe erosion (life 6.5 vs. 5 years), maintenance costs down 72% ($70,000 vs. $250,000/year). Australian mine used DN300 purge-equipped valves in tailings: zero clogging downtime (saving $100,000/year in cleaning costs).

IV.C. Coal Mining: Slurry Transport and Dewatering

U.S. coal mine installed 150 DN150 carbon steel/Stellite/PU V-port valves: 1.7x longer service life (2.5 vs. 1.5 years), 0.7 bar less pressure drop (12,000 kWh/valve/year savings = $216,000 total), 50% less sedimentation. German mine used DN100 electric V-port valves in dewatering: 70% less operator intervention, 10% better dewatering (coal water content 18 vs. 20%), $5/ton higher coal value.

IV.D. Mineral Processing: Grinding and Concentrate Transport

South African gold mine installed DN125 Stellite/PU V-port valves in grinding circuits: 8% better grinding efficiency (1.5% gold recovery increase), 2.3x longer service life (2.3 vs. 1 year), $140,000/year saved (maintenance + downtime). Canadian nickel mine used DN200 Class V valves in concentrate transport: 99% less product loss (0.001 vs. 0.1%), saving $500,000/year.

V. Installation and Maintenance Best Practices

Proper installation and maintenance maximize service life and reliability, tailored to mining’s harsh conditions.

V.A. Pre-Installation and Installation

Pre-installation: Inspect valves for damage/debris, clean/aline pipes (≤0.3 mm misalignment), verify material compatibility, calibrate torque tools. Installation: Vertical stem orientation (where possible), compatible gaskets (EPDM/PTFE), even flange torque (40–80 N·m), actuator alignment, purge port setup (3–5 bar, 5 min/8 hour flushing).

V.B. Preventive Maintenance

Monthly: Visual inspections for leaks/corrosion. Quarterly: Clean actuator air filters (pneumatic), purge port filters. Every 6 months: Lubricate stem/internals (2–3 mL packing, 5–10 mL body, molybdenum disulfide grease). Annual: Inspect seats (replace if ≥0.5 mm wear or excess leakage). Every 18 months: Inspect balls (re-polish if ≤0.2 mm wear, replace if ≥0.5 mm).

V.C. Troubleshooting and Repair

Common issues: Stem leakage (tighten packing/replace), seat leakage (replace seat/ball, flush purge), poor flow control (calibrate positioner, clean port), clogging (flush purge/manual clean), actuator failure (check air/power, replace damaged parts). Repair: Disassemble/clean/inspect components, recondition (re-polish), test before reinstallation—more cost-effective than replacement for DN ≥200.

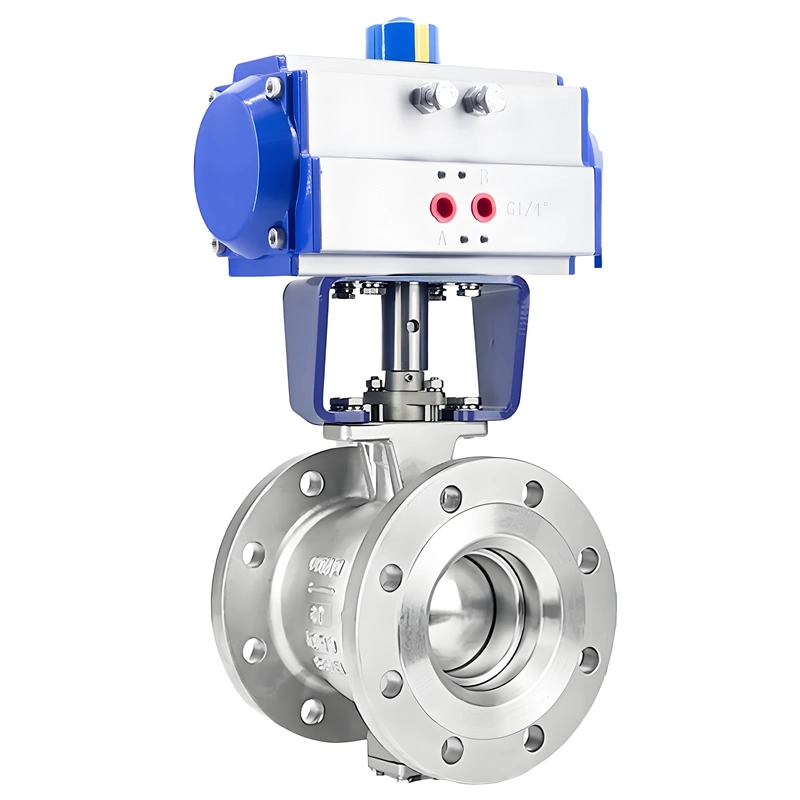

VI. Custom V-Port Ball Valves: Advantages for Mining Slurry Systems

TIANYU’s custom V-port ball valves are engineered for the harsh conditions of mining slurry systems, delivering precision flow control (±1% accuracy), exceptional wear resistance, and anti-clogging performance. Available in DN50–DN400, PN10–PN100, we tailor materials (Stellite, tungsten carbide, duplex 2205) and V-port angles (15°–90°) to your slurry’s abrasiveness and flow needs. Our valves reduce pressure drop by 25–40%, extend service life to 2–5 years, and cut maintenance costs by 70%. Backed by ISO 9001 and API 6D certifications, 100% performance testing, and 24/7 global support, TIANYU minimizes downtime and optimizes efficiency for copper, iron, coal, and mineral mining operations worldwide.