Chemical processing environments represent the ultimate test of industrial valve performance, combining aggressive media, extreme thermal profiles, and zero-tolerance safety requirements. With global chemical production projected to reach $6.8 trillion by 2028 and emissions regulations intensifying worldwide, TIANYU engineered globe valves deliver precision flow management certified with zero-bubble sealing integrity. Designed for critical applications from sulfuric acid concentration to caustic soda evaporation systems, these valves maintain fugitive emissions below 50 ppm while reducing total cost of ownership by 40% compared to conventional alternatives.

Key Takeaways

- Globe valves control flow accurately, keeping chemical reactions steady and products good.

- These valves can handle strong and harmful liquids, stopping leaks and protecting tools.

- Globe valves are important for systems with high pressure and heat, making them safer and work better.

- Their tough design helps make exact changes in batch processes, improving quality and cutting waste.

- Picking the right materials and knowing pressure limits help globe valves last longer and work well.

I. Precision Flow Control Architecture

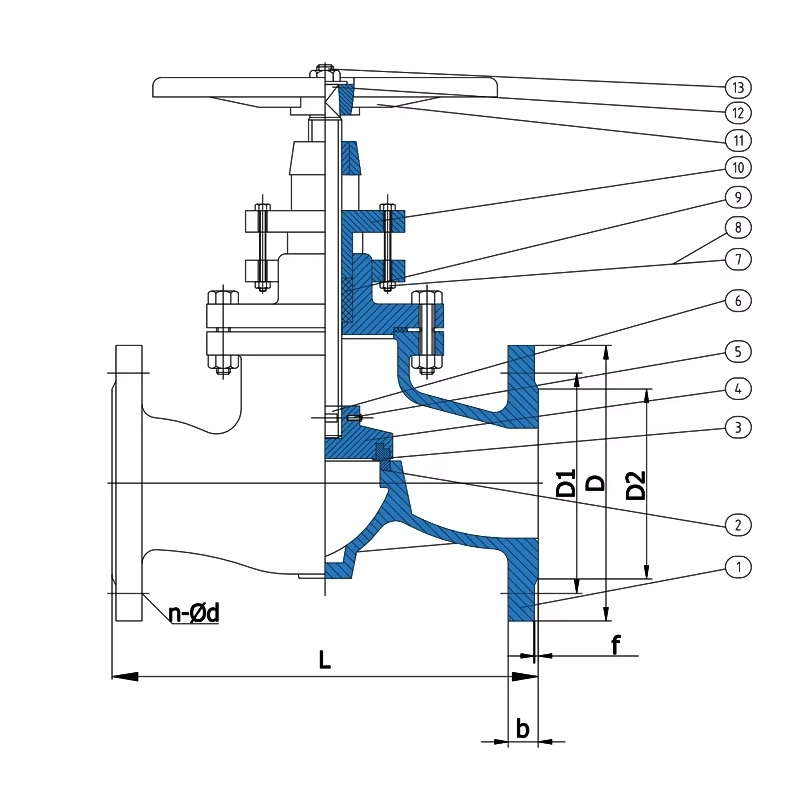

Parabolic Plug Technology

The proprietary parabolic plug geometry establishes logarithmic flow characteristics essential for stoichiometric processes. This delivers ±0.8% control accuracy at 10:1 turndown ratios, enabling exact pH adjustment in reactor feed systems. The multi-stage pressure reduction design dissipates 92% of cavitation energy, eliminating vapor bubble implosion that damages trim components in high-pressure drop applications. For abrasive services like phosphoric acid sludge handling, the optimized 35° seat angle prevents particulate accumulation while maintaining ANSI Class VI shutoff.

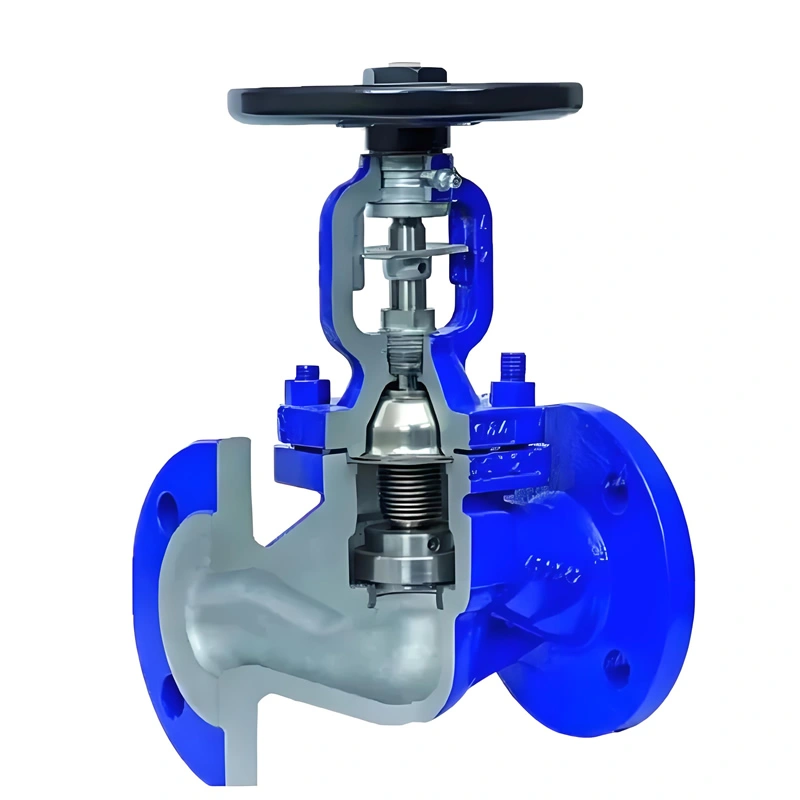

Multi-Barrier Stem Sealing System

-

Primary Metal Bellows: Welded 316L stainless steel construction rated for 2,500+ cycles, providing absolute isolation from corrosive media

-

Secondary Live-Loaded Packing: Flexible graphite/Kalrez composite rings with automatic compression adjustment, certified to API 622 fire-safe standards

-

Emergency Backseat: Pressure-activated metal-to-metal seal enabling safe maintenance under full operating conditions

Table: Performance Envelope Specifications

| Parameter | Standard Range | Extended Capabilities |

|---|---|---|

| Pressure Rating | ASME 150–2500 | Hypercompressible to 10,000 psi |

| Temperature Range | -196°C to +650°C | +800°C refractory configurations |

| Fugitive Emissions | ANSI VI (Bubble-Tight) | ISO 15848-1 Class A ≤50 ppm |

| Flow Capacity (Cv) | 5–480 | 800+ for high-volume reactors |

| Cycle Life | 100,000 operations | 250,000+ in clean service |

II. Corrosion Engineering Excellence

Application-Specific Metallurgy

-

Chloride Environments: Hastelloy C276 bodies with PREN >75 withstand 10,000 ppm Cl⁻ concentrations without stress corrosion cracking

-

Hydrogen Fluoride Service: Cold-worked Monel 400 trim (200+ HB hardness) prevents hydrogen embrittlement in anhydrous HF applications

-

Phosphoric Acid Slurries: Zirconium-clad internals with crevice corrosion immunity maintain <0.001 in/year wear rates in 54% P₂O₅ service

Surface Enhancement Technologies

-

Robotic Plasma Overlays: Precision deposition of 2.8-mm Hastelloy G30 layers maintaining corrosion resistance integrity with <3% dilution

-

Electroless Ni-PTFE Coatings: 120 μm composite layers with 12% PTFE infusion achieving Ra 0.4 μm finish to prevent polymer adhesion

-

Vapor-Deposited Silicon Carbide: 1,800 Vickers hardness surface treatment for erosion resistance in >30% solids slurries

III. Chemical Process Application Engineering

Sulfuric Acid Concentration Systems

Operating Challenge: Differential corrosion rates below 40°C (hydrated acid) and above 200°C (dehydrating acid)

Engineering Solution: Tantalum-lined bodies with boron-doped graphite packing

Performance Validation: 0.001 in/year corrosion rate at 180°C enabling 60-month service intervals

Caustic Soda Evaporators

Operating Challenge: Stress corrosion cracking at vapor-liquid interfaces from chloride contamination

Engineering Solution: Duplex steel UNS S31803 valves with stress-relieved trim and optimized phase balance

Performance Validation: Zero SCC after 100,000 thermal cycles in membrane cell operations

Acrylonitrile Reactor Control

Operating Challenge: Polymerization on trim surfaces causing flow restriction

Engineering Solution: Electropolished 316L trim (5Ra finish) with steam-jacketed bonnets

Performance Validation: 300% extended service life (12+ months) versus standard valves

IV. Emissions Control Technology

Sealing System Validation

-

Helium mass spectrometry testing at 1.5x design pressure confirming ≤10⁻⁹ mbar·L/s leak rates

-

Accelerated life testing of 5,000 full-stroke operations with thermal cycling (-196°C ↔ 450°C)

-

Seismic verification through 5g vibration across 5–150 Hz frequency spectrum

Intelligent Monitoring Systems

-

Acoustic emission arrays with 2 MHz ultrasonic sensors detecting bubble formation within 50 milliseconds

-

Laser-based VOC analyzers providing 0.1 ppm detection sensitivity integrated with plant DCS

-

Cloud-based prognostic algorithms processing 47 operational parameters to predict seal failure 3,200 hours in advance

V. Operational Economics Analysis

Total Cost of Ownership Comparison

| Cost Category | Conventional Valve | TIANYU Solution | 10-Year Savings |

|---|---|---|---|

| Seal Replacements | 9 @ $24,000/event | 1 event | $192,000 |

| Energy Consumption | 487 MWh | 312 MWh | $19,250 |

| Production Downtime | 34 days @ $112k/day | 7 days | $3,024,000 |

| Emission Compliance | $38,700/year | $2,100/year | $366,000 |

| Total Impact | $3,601,250 |

Maintenance Efficiency Advantages

-

Cartridge-style packing systems reducing stem seal replacement from 16 hours to 3.5 hours

-

Modular trim retrofit kits decreasing overhaul time by 68% through elimination of alignment procedures

-

Control stability maintaining <0.25%/year calibration drift versus 1.2% industry average

VI. Industry-Specific Performance Validation

HF Alkylation Unit Case Study

Application: Anhydrous hydrogen fluoride control valves

Challenge: Hydrogen embrittlement and uniform corrosion

Solution: Monel 400 trim with cold-worked hardness >200 HB

Results:

-

0.0005 in/year corrosion rate after 36 months operation

-

Zero fugitive emissions through full bellows containment

-

Elimination of quarterly maintenance shutdowns

Chlor-Alkali Membrane Cell Application

Application: 32% NaOH control at 90°C

Challenge: Chloride-induced stress corrosion cracking

Solution: Duplex steel construction with controlled 40-45% ferrite phase

Results:

-

100,000+ cycles without SCC initiation

-

60% reduction in valve maintenance costs

-

Compliance with EPA Method 21 emission standards

VII. Digital Integration Platform

Smart Valve Capabilities

-

Real-time torque monitoring with 0.1 N·m resolution detecting seal degradation

-

Fiber Bragg grating thermal sensors mapping seat temperature gradients within 1°C accuracy

-

Wireless HART connectivity for integration with plant asset management systems

Performance Analytics Dashboard

-

Leak probability algorithms with 93.5% prediction accuracy

-

Digital valve passports storing full manufacturing history and maintenance records

-

Automated emissions reporting for EPA Subpart VV compliance

Redefining Chemical Process Safety

TIANYU globe valves establish new benchmarks for chemical process safety and operational efficiency. With third-party validated zero-bubble performance, corrosion engineering exceeding NACE MR0175 requirements, and predictive maintenance capabilities, these valves transform emission control from regulatory compliance to competitive advantage. As the chemical industry advances toward bio-based feedstocks and electrified processes, TIANYU’s materials science expertise positions these valves as essential components for sustainable manufacturing.