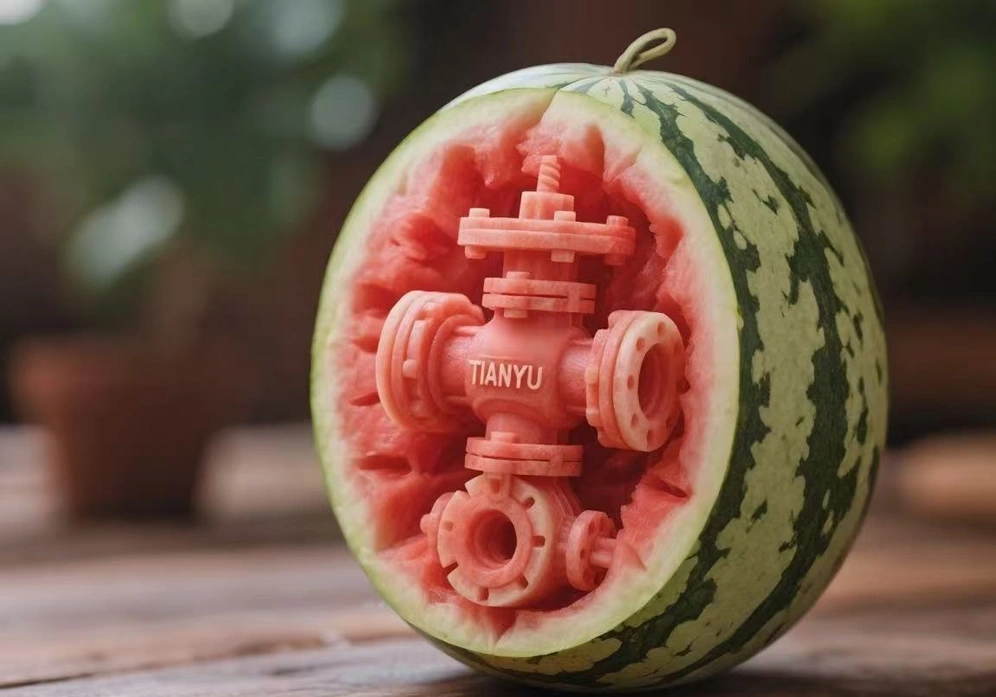

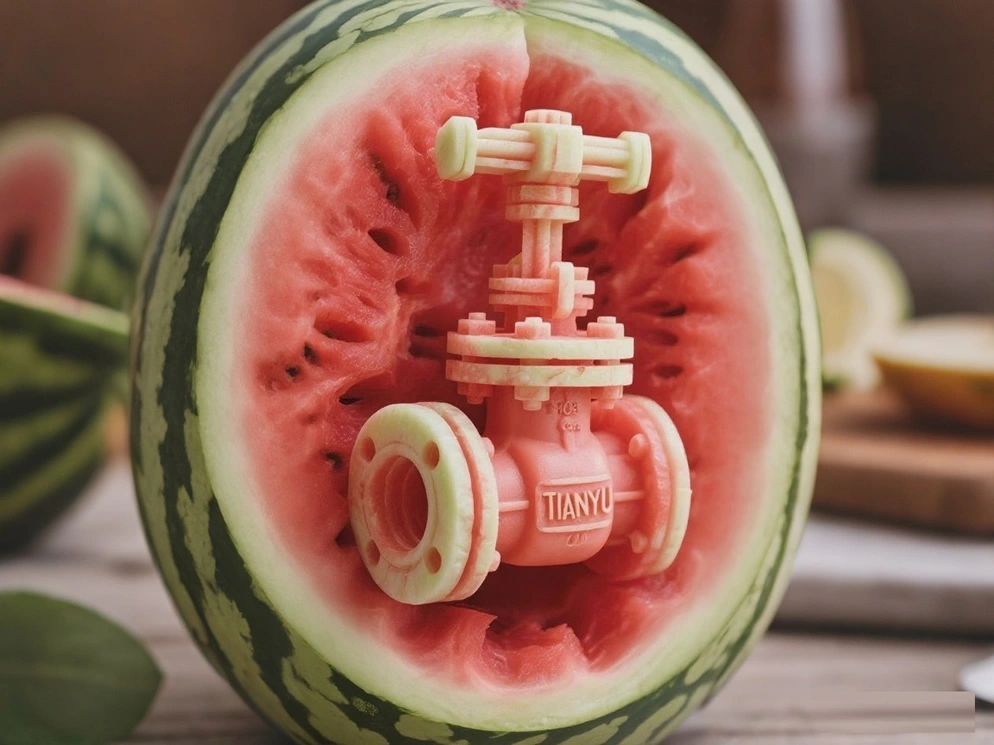

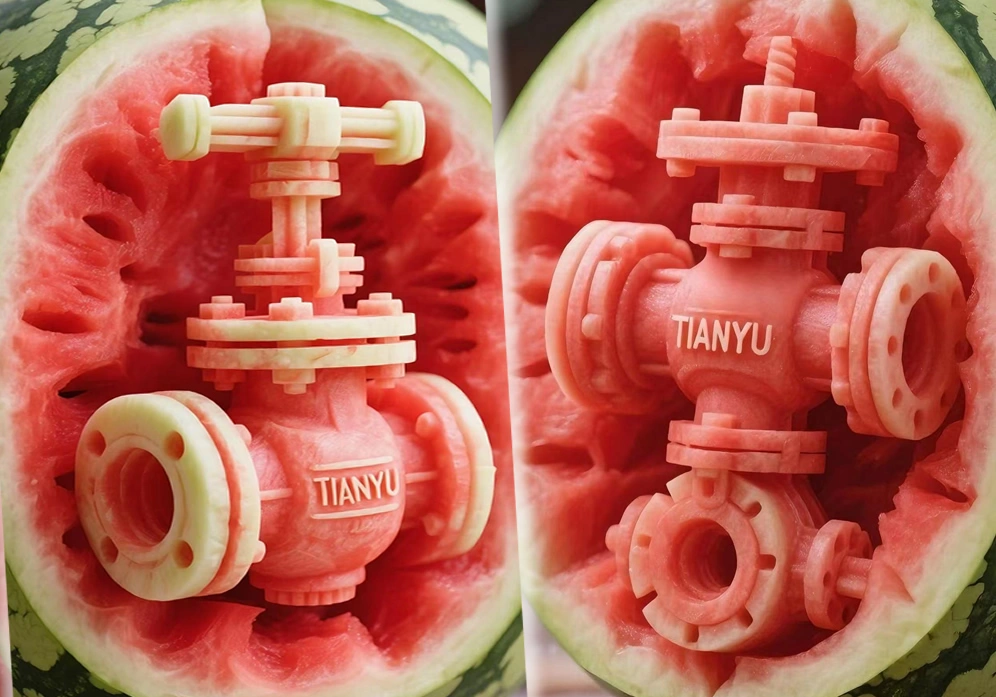

I. Summer Creativity: The Innovative Gene of Valves in Watermelon Carvings

When the scorching summer meets industrial valves, Tianyu writes a new story of the integration of industry and life with a wonderful watermelon – carving creativity. Carving the valve shape precisely on a watermelon is not just a novel visual collision, but also a vivid manifestation of the innovative spirit.

In the field of industrial valves, innovation is rooted in a profound understanding of industry needs. According to industry research, more than 70% of industrial accidents are related to valve failures. China Valve Manufacturers Tianyu is well aware that valves, as the “throat” components of process industries, connect key fields such as energy, chemical engineering, and municipal administration. Each precise control of fluid is crucial to the safe and stable operation of the system. This creativity is just like a microcosm of the innovative ecosystem – breaking conventions, interpreting product value from a unique perspective, and more importantly, indicating the ability to customize solutions for complex working conditions, turning creativity into productive forces.

II. Showing Strength at Exhibitions: Presenting Tianyu to the World

Tianyu has never been absent from the global industrial exhibition stage. From top – notch domestic events to overseas professional exhibitions, Tianyu confidently showcases its independently developed valves. The booths of Tianyu always attract the attention of global customers and peers, and behind this is the intuitive presentation of comprehensive strength.

(I) Brand Influence

With “TIANYU” as the brand identifier, Tianyu continues to make its voice heard at international exhibitions. In the past three years, the exhibition footprint has covered more than 20 countries and regions, communicating face – to – face with more than 500 overseas customers, collecting more than 2000 pieces of market feedback, and constantly calibrating the R & D and service directions. The reputation of “Tianyu Manufacturing” spreads with the exhibitions, and a brand network covering major global industrial regions is gradually built overseas. The annual growth rate of overseas orders reaches 18%.

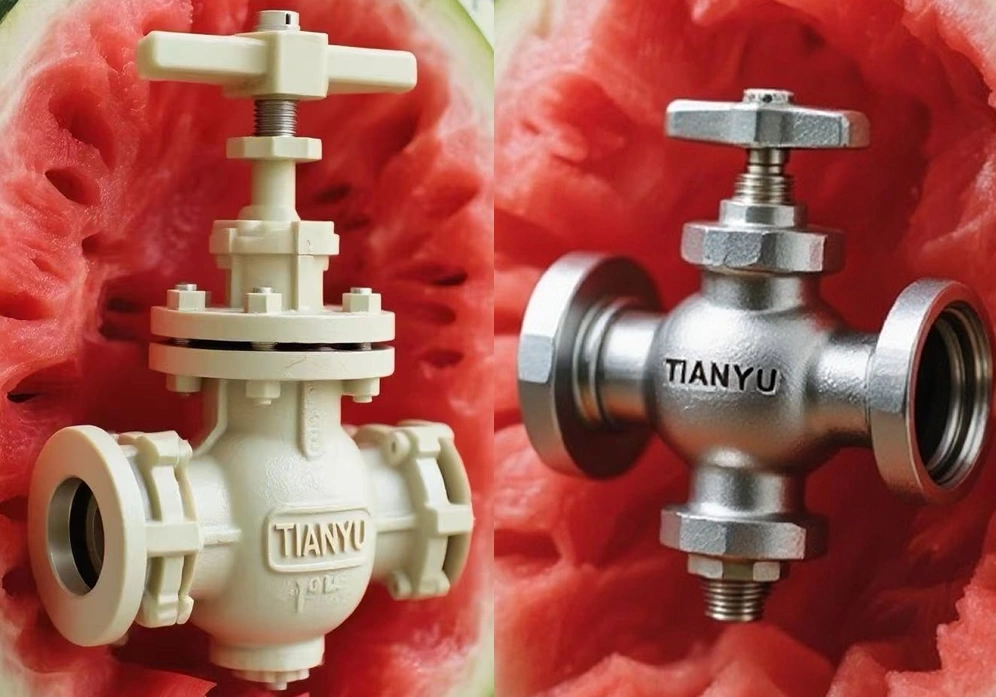

(II) Product Display Window

Exhibitions are the best display windows for Tianyu’s technologies and products. For the high – performance gate valves developed for the petrochemical field, through tests, under the working conditions of 100bar pressure and 400℃ high temperature, the sealing leakage is ≤ 1 drop per minute, and the anti – erosion life exceeds 100,000 cycles. The simulation of extreme working conditions at exhibitions allows customers to directly feel the reliability and advanced nature, laying a solid foundation of trust for business cooperation, and the order conversion rate reaches more than 35%.

III. Factory Strength: The “Hard – core” Backing of Industrial Valves

Walking into Tianyu’s production factory, the atmosphere of Industry 4.0 is overwhelming, which is the “hard – core” backing for the high – quality production of valves.

(I) Intelligent Production Layout

Tianyu has introduced an intelligent manufacturing system to realize full – process digital management and control. For incoming raw materials, 12 items of inspection such as spectral analysis and mechanical property testing are carried out, and the unqualified rate is controlled within 0.5%. The intelligent processing center processes valve bodies and stems with an error of ≤ ± 0.01mm, ensuring precision and consistency. The MES system dispatches in real – time, shortening the delivery cycle of conventional products to 15 days, and compressing the production cycle of customized products by 30%, flexibly responding to order demands.

(II) Stringent Quality System

Quality is the lifeline of Tianyu. A multi – dimensional inspection system has been established. The finished valves undergo pressure testing (1.5 times the working pressure), sealing testing (leakage ≤ 1/3 of the national standard), and life testing (simulating working conditions for more than 10,000 cycles). In the past five years, the defective rate of ex – factory valves is ≤ 0.3%, widely recognized in industries such as petroleum, natural gas, and electric power, and the repeat purchase rate of customers exceeds 60%.

(III) Talent and Technology Reserve

The factory gathers more than 200 R & D and manufacturing talents, including more than 50 senior engineers. It has established joint R & D centers with universities and research institutions, investing more than 50 million yuan in R & D in the past three years and obtaining more than 30 patents. In the research and development of high – performance sealing materials, with the help of university laboratories, a sealing component suitable for the temperature range of – 196℃ to 600℃ has been developed, filling the industry gap and enhancing core competitiveness.

IV. Manufacturing Process: The “Ingenuity” Code for Carving Industrial Valves

The excellent quality of Tianyu valves comes from the meticulous research of the manufacturing process, and each process hides the “ingenuity” code.

(I) Casting Process

The valve bodies are cast using lost – foam or precision casting, with a casting waste rate of ≤ 2%. The pouring temperature (± 5℃) and speed (± 0.5m/s) are controlled to ensure the internal compactness of the valve body. For complex valve bodies, the mold is optimized through simulation, and the dimensional accuracy error is ≤ ± 0.5mm, laying a foundation for processing.

(II) Processing Technology

The key components rely on high – precision CNC equipment, and multiple processes such as milling, boring, and turning cooperate. After grinding and lapping the valve seat sealing surface, the surface roughness Ra ≤ 0.8μm. Plasma surfacing of nickel – based alloy is adopted, and the thickness error of the surfacing layer is ≤ ± 0.1mm, ensuring the wear resistance and corrosion resistance of the sealing surface, and the sealing life exceeds 5 years.

(III) Assembly Process

The assembly is managed with precision. Workers control the installation position and torque of parts according to the process (error ≤ ± 5%). The intelligent test bench simulates working conditions and records data such as opening/closing torque and leakage. The performance compliance rate of ex – factory valves is 100%, and they operate stably and efficiently in actual use.

V. Product Advantages: A “Sharp Tool” for Solving Industrial Pain Points

In the fierce market competition, Tianyu’s products become a “sharp tool” for solving industry pain points with their advantages.

(I) Customized Adaptation

Tianyu provides customized valve solutions for customers. For special media, extreme working conditions, and special space requirements, through the application of special materials (such as Hastelloy and Monel), structural optimization (reducing flow resistance by 15%), and integration of intelligent modules, it can accurately adapt to scenarios. In the past two years, more than 100 customized projects have been completed, covering fields such as chemical engineering and nuclear power, solving the “incompatibility” problem of conventional products.

(II) High Efficiency and Energy Saving

Emphasis is placed on energy saving. The flow channel design is optimized, and a new hydraulic model is adopted. After the optimization of the flow channel structure of the eccentric semi – ball valve, the flow resistance coefficient is reduced by 20%. Compared with traditional valves, the energy consumption is reduced by 10% – 20%. After being applied by a petrochemical enterprise, the annual energy cost savings exceed one million yuan, contributing to the “dual – carbon” goal.

(III) Intelligent Interconnection

Intelligent technology is integrated. Some valves are equipped with intelligent positioners and sensors, which can collect data such as opening, temperature, and pressure in real – time and upload them to the platform through the Internet of Things. Customers can remotely monitor, give early warnings of faults, and control remotely, improving the intelligent management and control level of the system. After the application of intelligent valves, the equipment failure response time is shortened to within 1 hour, and the operation and maintenance cost is reduced by 25%.

VI. Customized Services: Tailoring for Industrial Needs

The complexity of industrial scenarios determines the individuality of valve needs. Tianyu uses a complete system to “tailor – make” for customers.

(I) In – depth Demand Mining

Pre – sales engineers go deep into the site, communicate with customers’ technical and operating personnel, and through on – site surveys and working condition simulations (with an accuracy of 90%), extract customized demands, providing a clear direction for design, and the demand understanding deviation rate is ≤ 5%.

(II) Customized Design and R & D

The R & D team customizes the design according to the demands, using 3D modeling and fluid simulation for verification. During the design process, communication is maintained, and the response time for scheme adjustment is ≤ 24 hours, ensuring that the results meet functional, technical, and economic demands, and the design scheme approval rate exceeds 95%.

(III) Full – process Service Guarantee

Full – process services are provided from production to after – sales. The production progress is fed back in real – time and subject to supervision; professional personnel are dispatched for installation guidance, and the installation defect rate is ≤ 1%; a rapid response mechanism is established for after – sales, with a 2 – hour response and 24 – hour on – site arrival, solving customers’ worries and building a deep – cooperation relationship.

The watermelon carving in the hot summer is a romantic expression of the innovative spirit. In the field of industrial valves, Tianyu showcases strength at exhibitions, builds quality in factories, creates high – quality products with processes, breaks pain points with products, and empowers development with services. In the future, Tianyu will uphold innovation, move towards higher quality, intelligence, and customization, provide more valuable solutions for global industrial customers, and make the “Tianyu Manufacturing” flag more and more brilliant.