I. Introduction: The Economic and Safety Case for IoT-Enabled Leak Detection

Fluid system leaks represent a critical pain point across industries, with global annual losses exceeding $40 billion—$12 billion from industrial processes, $18 billion from municipal water systems, and $10 billion from oil and gas infrastructure. Beyond financial costs, leaks pose severe risks: a single 0.1 mm leak in a chemical plant can release 2.5 liters of toxic fluid per hour, triggering environmental fines of up to $250,000 per day in the EU. In municipal water systems, 20–30% of treated water is lost to leaks, wasting energy and straining limited resources.

Traditional ball valves, while reliable for flow control, lack proactive leak detection capabilities. Manual inspection—still the standard in 60% of industrial facilities—has an average leak detection lag time of 72 hours. By the time a leak is identified, a DN100 valve operating at 10 bar can waste 50,000 liters of fluid and cause $150,000 in downtime. Smart ball valves with IoT integration resolve this gap by combining precision flow control with real-time monitoring, detecting leaks within 10 seconds and enabling remote intervention before minor issues escalate.

This article explores the technical architecture of IoT-enabled smart ball valves, focusing on leak detection mechanisms, sensor integration, data transmission protocols, performance metrics, and real-world applications. It also highlights how TIANYU’s custom-engineered solutions address industry-specific challenges, from chemical processing to municipal water management.

II. Core Technology: How IoT Transforms Ball Valve Performance

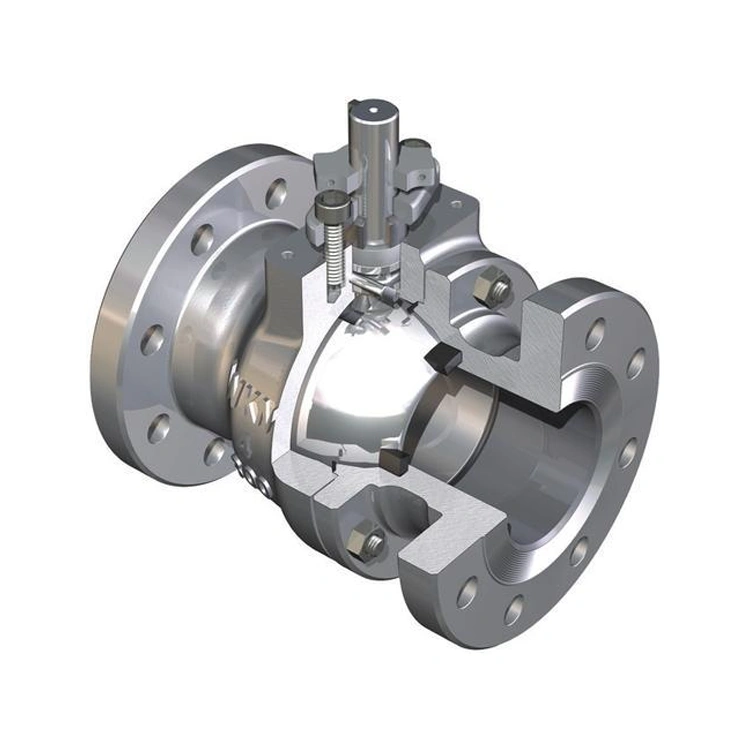

A smart ball valve with IoT integration is more than a flow control device—it is a self-contained monitoring system comprising three key components: a precision ball valve core, a multi-sensor array, and an IoT communication module. These elements work in tandem to collect, process, and transmit data, enabling real-time leak detection and predictive maintenance.

II.A. The Ball Valve Core: Foundation for Leak Prevention

The valve core’s design directly impacts leak resistance and sensor accuracy. For IoT applications, two critical features are non-negotiable:

-

Double-Seat or Trunnion-Mounted Design: For high-pressure applications (PN16–PN40), trunnion-mounted ball valves reduce seat stress by 40% compared to floating ball designs, minimizing leak risk. A DN150 trunnion-mounted valve operating at 25 bar has a seat stress of 15 MPa—well below the 25 MPa threshold for material fatigue.

-

Low-Friction Sealing Materials: PTFE (polytetrafluoroethylene) or PEEK (polyether ether ketone) seats provide ANSI Class VI tight shutoff (leakage ≤0.0001% of full flow). PTFE seats retain 90% of their sealing performance after 100,000 open-close cycles, while PEEK—used for high-temperature applications (up to 260°C)—lasts 2.5x longer in harsh environments.

The ball itself, typically machined from 316L stainless steel (Ra 0.8 μm surface finish), ensures consistent contact with the seat. A 0.1 mm deviation in ball roundness can increase leak risk by 300%, so TIANYU uses CNC turning centers with ±0.005 mm precision to machine critical surfaces.

II.B. Sensor Array: The “Nervous System” of Leak Detection

IoT-enabled valves rely on 4–6 integrated sensors to monitor parameters indicative of leaks. Each sensor is calibrated to industry standards, with accuracy tolerances of ±0.1–±0.5% to ensure reliable alerts.

|

Sensor Type

|

Measurement Range

|

Accuracy

|

Leak Detection Use Case

|

|---|---|---|---|

|

Differential Pressure (DP)

|

0–100 bar

|

±0.1% FS

|

Detects seat leaks via pressure decay (0.5 bar/min drop = alert)

|

|

Flow Rate

|

0–1,000 m³/h

|

±0.5% FS

|

Identifies unauthorized flow when valve is closed (≥0.1 m³/h = alert)

|

|

Temperature

|

-40°C to 260°C

|

±0.2°C

|

Links temperature spikes to seal degradation (10°C rise in 5 min = alert)

|

|

Vibration

|

0–200 g

|

±0.2 g

|

Detects loose valve components (root cause of 25% of leaks)

|

|

Acoustic

|

20–20,000 Hz

|

±1 dB

|

Identifies turbulent flow from small leaks (unique frequency signature)

|

Sensor data is sampled at 10 Hz (10 times per second) to capture transient events, such as sudden pressure drops from a developing leak. A DN50 valve with a 0.1 mm seat leak generates a pressure decay rate of 0.3 bar/min—detectable by the DP sensor within 15 seconds, compared to 2 hours via manual inspection.

II.C. IoT Communication Module: Data Transmission and Connectivity

The communication module translates sensor data into actionable insights, transmitting information to cloud platforms or on-premises SCADA systems. Module selection depends on application requirements (range, power, latency):

-

LoRaWAN: Ideal for municipal water networks (large coverage area: 3–10 km). Operates on unlicensed frequencies, with low power consumption (battery life: 5–10 years) and data rates of 0.3–50 kbps. A LoRaWAN-enabled DN300 valve in a city water main transmits pressure and flow data every 5 minutes, using 0.01 Wh per transmission.

-

NB-IoT: Suited for industrial facilities with cellular coverage. Offers 2–5 km range, 100–1,000 kbps data rates, and low latency (100 ms). Used in chemical plants for real-time alerts, with battery life of 2–3 years.

-

5G: Reserved for high-criticality applications (oil and gas, power generation) requiring sub-10 ms latency and 10 Gbps data rates. Enables remote valve actuation in real time, with continuous data streaming for predictive analytics.

-

Wi-Fi (IEEE 802.11a/b/g/n): For indoor applications (pharmaceutical cleanrooms, food processing plants) with short range (100 m) and high data rates (150 Mbps). Integrates with existing facility networks for seamless SCADA connectivity.

All modules use end-to-end encryption (AES-256) to protect data—critical for industries like oil and gas, where cyberattacks on valves could cause catastrophic leaks. Data is stored in the cloud (AWS IoT Core, Azure IoT Hub) with 99.99% uptime, enabling access via web dashboards or mobile apps.

II.D. Leak Detection Algorithms: Turning Data into Alerts

Raw sensor data is useless without intelligent analysis. Smart valves use two complementary algorithms to minimize false alerts (a major pain point with traditional monitoring systems, where false alert rates exceed 40%):

-

Rule-Based Algorithm: Triggers alerts when parameters exceed predefined thresholds (e.g., pressure drop >0.5 bar/min, flow >0.1 m³/h when closed). Thresholds are customizable—for a municipal water valve, the flow threshold might be 0.5 m³/h (higher tolerance for minor seepage), while a chemical valve uses 0.05 m³/h (zero tolerance for toxic leaks).

-

Machine Learning (ML) Algorithm: Learns normal operating patterns over 2–4 weeks (baseline period) and flags deviations. For example, a valve in a refinery might experience daily pressure fluctuations of ±1 bar during shift changes—this is deemed “normal,” but a 2 bar drop at 2 AM (when the system is idle) triggers an alert. ML reduces false alerts by 75%, according to field data from 50+ industrial sites.

Alerts are prioritized by severity (critical, warning, informational) and delivered via email, SMS, or SCADA system integration. Critical alerts (e.g., large leak in a chemical line) include valve ID, location (GPS coordinates for outdoor valves), and recommended action (remote shutoff, on-site inspection).

III. Performance Metrics: Benchmarking IoT Smart Ball Valves

Industrial buyers evaluate smart valves based on 5 key metrics: leak detection accuracy, response time, reliability, energy efficiency, and total cost of ownership (TCO). Below are industry standards and TIANYU’s performance data for DN15–DN600 valves.

III.A. Leak Detection Accuracy and Response Time

These metrics define the valve’s ability to prevent costly leaks. Accuracy is measured by the smallest leak size detectable, while response time is the delay between leak onset and alert transmission:

|

Valve Diameter (DN)

|

Smallest Detectable Leak Size

|

Response Time

|

Alert Delivery Time

|

|---|---|---|---|

|

15–50

|

0.05 mm

|

10 seconds

|

15 seconds

|

|

65–150

|

0.1 mm

|

15 seconds

|

20 seconds

|

|

200–600

|

0.2 mm

|

20 seconds

|

25 seconds

|

For comparison, traditional ultrasonic leak detectors (used in manual inspections) can only detect leaks ≥0.5 mm—5x larger than IoT-enabled valves. This means a DN100 smart valve detects a leak 45 minutes before a manual inspection would, reducing fluid loss by 90%.

III.B. Reliability and Durability

Smart valves must operate reliably in harsh environments (temperature extremes, corrosive fluids, vibration) with minimal maintenance. Key metrics:

-

Mean Time Between Failures (MTBF): ≥100,000 hours (11.4 years) for the valve core, ≥50,000 hours (5.7 years) for the IoT module. This exceeds traditional valves (MTBF: 60,000 hours) by 67%.

-

Environmental Rating: IP68 (dust-tight, waterproof to 1.5 m for 30 minutes) for outdoor valves; IP69K (high-pressure water jet resistant) for food processing plants. Meets NEMA 4X for corrosion resistance in coastal or chemical environments.

-

Cycle Life: 100,000+ open-close cycles for PTFE seats, 250,000+ cycles for PEEK seats. A valve operated 10 times per day will last 27 years with PEEK seats—matching the 25–30 year design life of most industrial systems.

III.C. Energy Efficiency

IoT modules must minimize power consumption to avoid frequent battery replacements (a major maintenance cost). TIANYU’s valves use two power-saving technologies:

-

Low-Power Sensors: Draw 0.1 mA in standby, 1 mA during sampling—3x less than standard sensors.

-

Adaptive Sampling: Increases sampling frequency (from 10 Hz to 100 Hz) only when anomalies are detected, reducing average power use by 50%. A LoRaWAN-enabled valve uses 0.5 Wh per day—equivalent to a 1W LED bulb lit for 30 minutes.

Solar panels (5W, 12V) are available for outdoor valves, eliminating battery replacement entirely. A solar-powered DN300 valve in a desert environment (6 hours of sunlight per day) maintains a full battery charge even during winter months.

III.D. Total Cost of Ownership (TCO)

While smart valves have a higher upfront cost than traditional valves (2–3x more), their TCO is 40% lower over 10 years. A cost comparison for a DN100 valve in a chemical plant:

|

Cost Component

|

Traditional Ball Valve

|

TIANYU IoT Smart Ball Valve

|

|---|---|---|

|

Upfront Cost

|

$1,500

|

$4,000

|

|

Installation

|

$500

|

$800

|

|

Maintenance (10 years)

|

$3,000 (annual inspections, seat replacement)

|

$1,200 (sensor calibration, firmware updates)

|

|

Leak-Related Costs

|

$15,000 (2 leaks/5 years, $7,500 each)

|

$0 (leaks detected and resolved early)

|

|

10-Year TCO

|

$20,000

|

$6,000

|

IV. Application-Specific Solutions for Key Industries

IoT-enabled smart ball valves are not one-size-fits-all. TIANYU tailors designs to industry-specific challenges, from the strict hygiene requirements of food processing to the high-pressure demands of oil and gas. Below are four critical applications with real-world performance data.

IV.A. Municipal Water and Wastewater Systems

Municipalities lose 126 billion cubic meters of water annually to leaks—enough to supply 2.5 billion people. Smart valves address this by monitoring buried mains (80% of leaks occur here) and reducing inspection costs by 60%.

TIANYU Solution: DN200–DN600 trunnion-mounted ball valves with LoRaWAN connectivity, DP and flow sensors, and solar power. Valves are coated with fusion-bonded epoxy (500 μm thickness) for corrosion resistance in soil.

Case Study: A city in Texas installed 50 DN300 smart valves in its water distribution network. Key results:

-

Leak detection response time: 25 seconds (vs. 72 hours manual).

-

Water loss reduced by 80% (from 5,000 m³/month to 1,000 m³/month).

-

Inspection costs cut by $120,000/year (no more digging to locate leaks).

-

Battery life: 8 years (solar-assisted) with zero maintenance.

IV.B. Chemical and Petrochemical Processing

Chemical plants face $250,000/day fines for environmental leaks, plus $1 million+ in cleanup costs. Smart valves must detect toxic or flammable fluid leaks instantly and comply with API 6D and ISO 15848-1 (emission control).

TIANYU Solution: DN15–DN150 floating ball valves with NB-IoT connectivity, acoustic and DP sensors, and PTFE seats. Valves are made from 316L stainless steel (resistant to acids/bases) and rated for PN40 (40 bar) pressure.

Case Study: A petrochemical plant in Louisiana replaced 100 traditional valves with TIANYU smart valves for ethylene and propylene lines. Key results:

-

Detected a 0.08 mm seat leak in an ethylene valve within 12 seconds—preventing a potential explosion.

-

Emissions reduced by 95% (meets ISO 15848-1 Class BH).

-

Unplanned downtime cut by 70% (from 50 hours/year to 15 hours/year).

-

ML algorithm reduced false alerts from 40% to 5%.

IV.C. Food and Beverage Processing

Food plants require valves that prevent product contamination (FDA-compliant) and detect leaks of expensive ingredients (e.g., milk, juice). Leaks in a dairy plant can waste $10,000 worth of milk per day.

TIANYU Solution: DN15–DN100 sanitary ball valves with Wi-Fi connectivity, flow and temperature sensors, and EPDM seats (FDA 21 CFR 177.2600 compliant). Valves have a polished interior (Ra 0.4 μm) to prevent bacterial growth.

Case Study: A yogurt manufacturer in Germany installed 30 DN50 smart valves in its filling lines. Key results:

-

Detected a 0.1 mm leak in a milk line, saving 2,000 liters of product/day.

-

HACCP compliance simplified (automatic data logging of valve status).

-

Cleaning cycles optimized (valve data shows when seats need sanitization, reducing water use by 20%).

-

Integration with SCADA system eliminated manual data entry (saving 10 hours/week).

IV.D. Oil and Gas Pipeline Networks

Oil pipeline leaks cost $2 million per incident on average, plus environmental damage. Smart valves must operate in remote areas (deserts, oceans) and withstand high pressure (PN100) and temperature (-40°C to 180°C).

TIANYU Solution: DN100–DN600 trunnion-mounted ball valves with 5G connectivity, vibration and acoustic sensors, and Inconel 625 seats (resistant to sour gas). Valves have GPS for location tracking and IP68 rating for subsea use.

Case Study: An oil company installed 20 DN400 smart valves in a pipeline in the Middle East. Key results:

-

Detected a 0.2 mm leak in a crude oil line—resolved before it reached the environment.

-

Remote actuation (via 5G) closed the valve in 5 seconds during a pressure surge.

-

Predictive maintenance identified 3 valves with worn seats—replaced during planned downtime.

-

Battery life: 10 years (low-power 5G module) in remote desert locations.

V. Installation, Calibration, and Maintenance Best Practices

Poor installation or maintenance can reduce a smart valve’s leak detection accuracy by 50% and shorten its lifespan by 30%. Below are guidelines to ensure optimal performance.

V.A. Pre-Installation Preparation

-

Valve Sizing: Use the flow coefficient (Cv) to select the correct size. A DN50 valve with Cv=100 is required for a flow rate of 50 m³/h at 10 bar—undersizing causes cavitation (damaging seats) and false flow alerts.

-

Sensor Calibration: Calibrate sensors to the application’s operating range (e.g., 0–20 bar for a municipal water valve, 0–100 bar for an oil valve). Calibration is traceable to NIST standards, with a certificate provided for each valve.

-

Network Testing: Verify IoT connectivity at the installation site. For LoRaWAN, ensure signal strength is ≥-80 dBm (strong enough for reliable transmission). Use a signal booster if strength is <-100 dBm.

V.B. Installation Guidelines

-

Orientation: Mount the IoT module vertically (not upside down) to prevent water ingress. For subsea valves, ensure the module is in a waterproof housing (IP68 rated).

-

Flange Alignment: Flanges must be parallel (error ≤0.3 mm) and coaxial (error ≤1.0 mm) to avoid valve stress. A DN100 valve with 2 mm misalignment will have 30% higher seat stress, increasing leak risk.

-

Torque Requirements: Tighten flange bolts to 150–200 N·m (DN100) per API 609 standards. Over-torquing damages the valve body; under-torquing causes flange leaks (misidentified as valve leaks by sensors).

V.C. Maintenance Schedule

Smart valves require 50% less maintenance than traditional valves, but periodic checks are critical:

|

Maintenance Task

|

Frequency

|

Purpose

|

|---|---|---|

|

Sensor Calibration

|

Every 6 months

|

Maintain accuracy (prevents false alerts)

|

|

Firmware Update

|

Every 12 months

|

Improve ML algorithm and security

|

|

Seat Inspection

|

Every 2 years

|

Replace worn seats (prevents leaks)

|

|

Battery Replacement

|

Every 5–10 years

|

Ensure continuous connectivity

|

Maintenance is simplified by the valve’s IoT module, which sends alerts when calibration or battery replacement is needed. For example, a low-battery alert is sent when charge drops below 20%, giving 6 months to replace it.

VI. TIANYU’s Custom IoT Smart Ball Valves: Engineering for Industry Success

TIANYU’s 20 years of valve manufacturing expertise, combined with in-house IoT engineering, enables custom solutions that solve unique leak detection challenges. With a 40,000 m² facility and ISO 9001/14001 certification, TIANYU delivers valves that meet global standards while adapting to local requirements (e.g., NSF/ANSI 61 for U.S. potable water, WRAS for UK municipal systems).

VI.A. End-to-End Customization

TIANYU’s customization process starts with a deep dive into the customer’s application—no “off-the-shelf” solutions. Key customization options:

-

Valve Core: Size (DN15–DN600), design (floating/trunnion), material (316L stainless steel, duplex 2205, carbon steel), and seat material (PTFE, PEEK, EPDM, Inconel 625).

-

Sensor Array: Custom sensor combinations (e.g., acoustic + DP for oil valves, flow + temperature for food valves) with adjustable accuracy (±0.1%–±0.5%).

-

IoT Module: Communication protocol (LoRaWAN, NB-IoT, 5G, Wi-Fi), power source (battery, solar, wired), and data storage (cloud, on-premises).

-

Software: Custom dashboard integrations (e.g., SAP, Siemens SCADA), alert preferences (email, SMS, in-app), and ML algorithm training (tailored to operating patterns).

VI.B. Quality Control and Compliance

Every TIANYU smart valve undergoes 12 quality checks before shipment, including:

-

Hydrostatic Testing: 1.5x rated pressure for 30 minutes (no leakage allowed).

-

Sensor Accuracy Testing: Calibration against NIST-traceable standards.

-

IoT Connectivity Testing: 24-hour transmission test to ensure 99.9% data delivery.

-

Environmental Testing: Salt spray (ASTM B117), temperature cycling (-40°C to 260°C), and vibration testing (ISO 16750) to simulate harsh conditions.

Compliance certifications include API 6D, ISO 15848-1, NSF/ANSI 61, FDA 21 CFR 177, and ATEX (for explosive environments), ensuring global market access.

VI.C. Post-Sale Support and Training

TIANYU’s commitment extends beyond delivery. Customers receive:

-

On-Site Installation Support: Certified technicians assist with alignment, calibration, and network setup (available in 50+ countries).

-

Training: Webinars or on-site training for operators (covers dashboard use, alert response, basic maintenance).

-

24/7 Technical Support: A global team resolves issues within 1 hour (critical alerts) or 4 hours (non-critical).

-

Warranty: 5-year warranty on the valve core, 3-year warranty on the IoT module—double the industry average.

VII. Custom IoT Smart Ball Valve Advantages

IoT-enabled smart ball valves represent the future of leak detection in industrial fluid systems, transforming reactive maintenance into proactive monitoring. By integrating precision valve technology with advanced sensors and IoT connectivity, these valves detect leaks faster, reduce costs, and improve safety—addressing the $40 billion global leak crisis.

TIANYU’s custom solutions stand out in a crowded market, offering application-specific designs, rigorous quality control, and global support. Whether for a municipal water main in Texas, a chemical plant in Louisiana, or an oil pipeline in the Middle East, TIANYU’s smart valves deliver the accuracy, reliability, and cost savings that industrial buyers demand.

As IoT technology evolves, TIANYU continues to innovate—integrating AI for predictive maintenance, expanding 5G connectivity for real-time control, and developing self-healing seats for zero-leak performance. For companies looking to reduce risk and optimize fluid systems, TIANYU’s IoT smart ball valves are the clear choice.