Large-diameter water Butterfly Valves mains (DN>300) form the backbone of municipal water supply, wastewater treatment, and industrial process systems, transporting 50–90% of potable water and 70% of wastewater in urban areas. A single DN1200 water main, for example, can deliver 12,000 cubic meters of water per hour—enough to supply 200,000 residents. The valves controlling these mains face unique challenges: high operating torque (up to 2,500 N·m for DN1200 valves), exposure to variable pressure (2–16 bar), and the need for reliable operation to avoid costly shutdowns (municipal water main outages cost an average of $150,000 per hour in the U.S.).

Manual Large-diameter butterfly valves, while cost-effective for small diameters (DN<300), become impractical for DN>300 systems: a DN600 manual valve requires 500 N of force to operate—exceeding the ergonomic limit for a single worker. Gear-operated butterfly valves resolve this by integrating a gear reduction system that amplifies torque while reducing input force, making them the standard for large-diameter water applications. When properly engineered, these valves deliver 15–20 years of service life, reduce maintenance costs by 40%, and ensure compliance with global standards (API 609, NSF/ANSI 61 for potable water).

This article examines the technical principles of gear-operated butterfly valves for DN>300 water mains, focusing on gear system design, material selection, performance metrics, installation best practices, and real-world applications. It also highlights how TIANYU’s custom-engineered solutions address the unique demands of large-diameter water infrastructure.

II. Core Design Principles: How Gear Operation Enables Large-Diameter Valve Control

The effectiveness of a gear-operated butterfly valve lies in its ability to balance torque amplification, operational efficiency, and structural integrity. Unlike manual valves (which rely on direct stem rotation) or automated valves (which use pneumatic/electric actuators), gear-operated valves use a mechanical gear train to convert low-input force into high-output torque—critical for moving the large discs (up to 1.5 meters in diameter) in DN>300 systems.

II.A. Gear Reduction Systems: Torque Amplification Fundamentals

Gear systems for large-diameter butterfly valves use spur gears or bevel gears (for 90° input/output alignment) with a reduction ratio of 5:1 to 20:1. The reduction ratio is defined as the number of gear teeth on the driven gear (connected to the valve stem) divided by the number on the driving gear (connected to the handwheel). A 10:1 ratio, for example, means 10 rotations of the handwheel produce 1 rotation of the valve stem—amplifying torque by 10x while reducing input force by 90%.

Key performance data for gear reduction systems:

-

Input Force Reduction: A DN600 valve requiring 1,200 N·m of torque to operate needs only 120 N·m of input force with a 10:1 gear ratio—translating to 30 N of hand force (vs. 300 N for a manual valve).

-

Operational Speed: Gear-operated valves require 10–30 handwheel rotations for full 90° disc movement (DN300–DN1200), balancing speed and torque. A DN300 valve with a 5:1 ratio takes 10 rotations (30 seconds), while a DN1200 valve with a 20:1 ratio takes 30 rotations (90 seconds).

-

Efficiency: Spur gear systems achieve 95–98% efficiency (minimal energy loss), while bevel gears (used for tight spaces) operate at 92–95% efficiency—ensuring most input force is converted to usable torque.

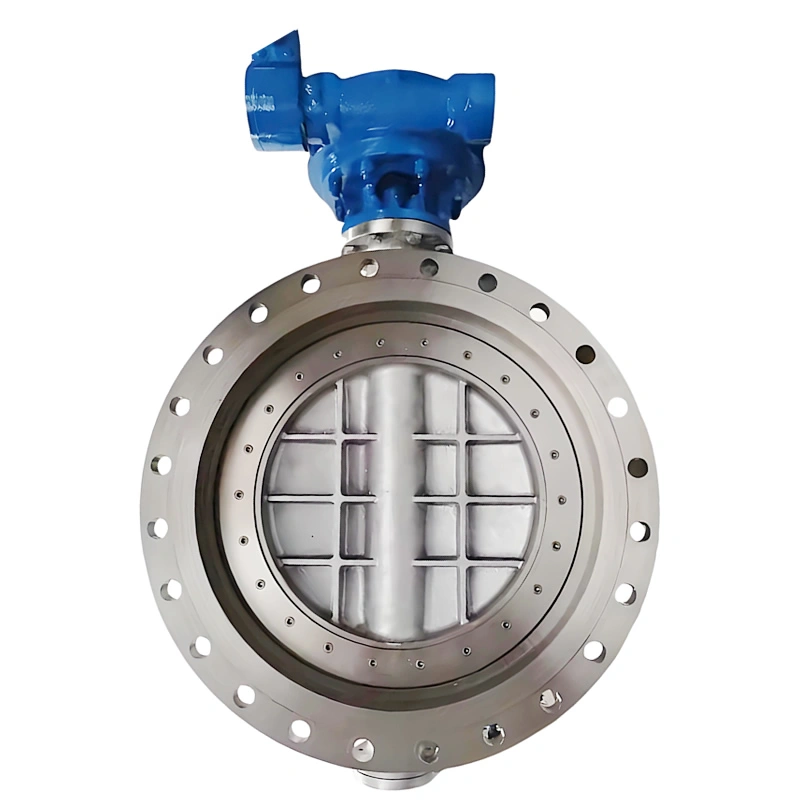

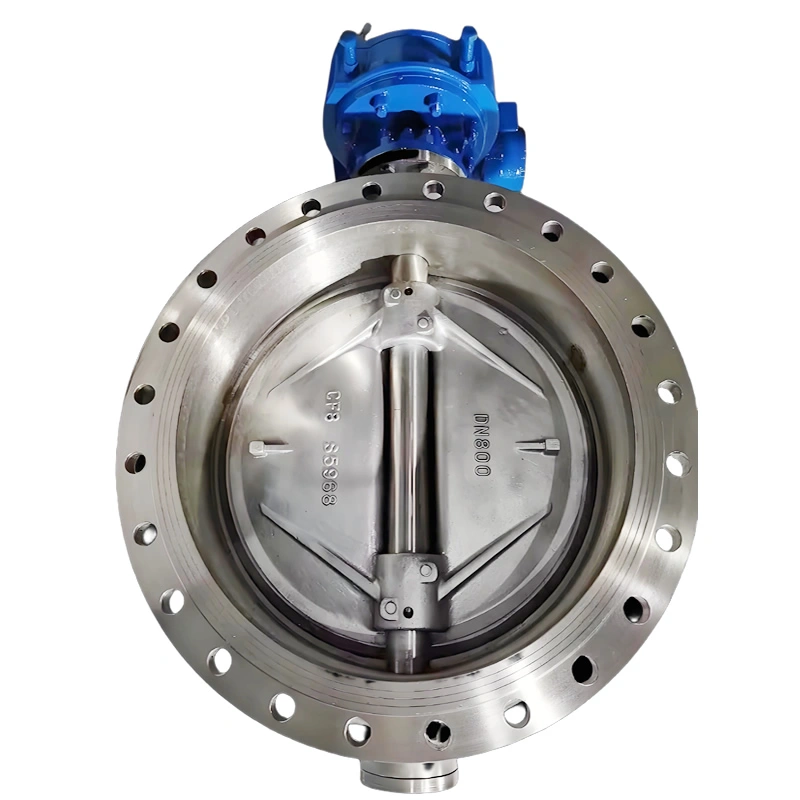

II.B. Butterfly Valve Integration: Disc and Seat Design for DN>300

The gear system works in tandem with the butterfly valve’s disc and seat to ensure smooth operation and tight sealing—critical for water mains, where even 0.1% leakage from a DN1200 valve wastes 12 cubic meters of water per hour. Key design features for DN>300 valves include:

-

Double-Eccentric Disc Geometry: The disc axis is offset from both the pipe centerline and the seat centerline, reducing friction between the disc and seat by 60% compared to single-eccentric designs. This lowers required torque by 30%—a DN1000 valve with a double-eccentric disc needs 1,800 N·m of torque, vs. 2,500 N·m for a single-eccentric model.

-

Full-Port Disc Profile: The disc diameter matches the pipe inner diameter when open, minimizing pressure drop (flow resistance coefficient ζ = 0.3–0.5). A DN600 full-port valve creates only 0.2 bar of pressure drop at 5,000 cubic meters/hour—reducing pump energy use by 15% compared to reduced-port valves (ζ = 1.2).

-

Elastomeric or Metal Seats: For potable water, EPDM or FKM elastomeric seats provide ANSI Class VI tight shutoff (leakage ≤0.0001% of full flow). For wastewater or industrial applications (abrasive media), Stellite 6 metal seats offer 10x longer service life (150,000+ cycles vs. 15,000 cycles for elastomers).

II.C. Gear Box Construction: Durability for Water Environments

Gear boxes for water mains must resist corrosion (from buried or wet environments) and prevent water ingress (which causes gear jamming). Typical construction features include:

-

Housing Material: Cast aluminum (IP67 rating, weight 8 kg for DN300) or ductile iron (IP68 rating, weight 25 kg for DN1200) with a fusion-bonded epoxy coating (500 μm thickness) for corrosion resistance. Testing per ASTM B117 (1,000-hour salt spray) shows ≤0.005 mm/year corrosion rate—suitable for coastal or wastewater applications.

-

Gear Material: Case-hardened steel (4140 alloy) with a Rockwell hardness of HRC 58–62, resisting wear even after 100,000+ operations. Gear teeth are precision-machined to ISO 5396 Class 6, ensuring smooth meshing and minimal noise (≤65 dB during operation).

-

Sealing and Lubrication: Nitrile O-rings (waterproof) and food-grade lubricant (NSF H1 certified for potable water) fill the gear box, preventing water ingress and reducing friction. Lubricant has a viscosity index of 150, maintaining performance across -20°C to 80°C—critical for outdoor installations in extreme climates.

III. Material Selection: Matching Valves to Water Main Conditions

Large-diameter Butterfly Valves water mains vary widely in operating conditions—from potable water (pH 6.5–8.5, chlorine residual 0.5–4 mg/L) to wastewater (pH 5.0–9.0, solids content 5–10%) to industrial cooling water (pH 7.0–11.0, temperature up to 80°C). Material selection for gear-operated butterfly valves must balance corrosion resistance, strength, and cost.

III.A. Valve Body Materials

The body is the primary structural component, supporting the gear system and withstanding system pressure. Common materials for DN>300 valves include:

|

Material

|

Key Properties

|

Ideal Applications

|

Cost Relative to Ductile Iron

|

|---|---|---|---|

|

Ductile Iron (ASTM A536 Grade 65-45-12)

|

Tensile strength 450 MPa, yield strength 310 MPa, corrosion-resistant with epoxy coating

|

Municipal potable water, wastewater (non-abrasive)

|

100%

|

|

316L Stainless Steel (ASTM A351 CF8M)

|

16–18% Cr, 10–14% Ni, 2–3% Mo; corrosion rate ≤0.001 mm/year in saltwater

|

Coastal water mains, industrial cooling water (chlorides)

|

400%

|

|

Duplex 2205 (ASTM A890)

|

Tensile strength 620 MPa (2x ductile iron), resistant to stress corrosion cracking (SCC)

|

High-pressure water mains (10–16 bar), sour water (H₂S)

|

550%

|

For example, a DN800 ductile iron valve with an epoxy coating costs $8,000 and lasts 15 years in municipal water service—vs. a 316L stainless steel valve ($32,000) that lasts 25 years in coastal applications. The total cost of ownership (TCO) for stainless steel becomes lower after 12 years, making it a long-term investment for harsh environments.

III.B. Disc and Seat Materials

The disc and seat directly impact torque requirements and sealing performance. Material combinations are tailored to media type:

-

Potable Water: Ductile iron disc (epoxy-coated) + EPDM seat. EPDM resists chlorine degradation (retains 90% tensile strength after 10,000 hours in 5 mg/L chlorine) and meets NSF/ANSI 61 for no contamination (extractables ≤0.001 mg/L).

-

Wastewater: 316L stainless steel disc + Nitrile (NBR) seat. NBR resists oil and grease (common in wastewater) and has a hardness of Shore A 70–80 for wear resistance.

-

Industrial Cooling Water: Duplex 2205 disc + Stellite 6 metal seat. Stellite 6 (cobalt-chromium alloy) withstands 80°C temperatures and abrasive solids (5% sand content), with a service life of 200,000+ cycles.

III.C. Gear System Materials

Gear components must resist wear and corrosion without contaminating potable water:

-

Gears: Case-hardened 4140 steel (core hardness HRC 30, surface hardness HRC 60) for strength and wear resistance.

-

Handwheel: Glass-reinforced nylon (GRN) for potable water (lightweight, corrosion-proof) or cast iron for industrial applications (impact resistance).

-

Fasteners: 304 stainless steel bolts and nuts (ASTM A193 Grade B8) to prevent rust leaching into water mains.

IV. Performance Metrics: Critical Specifications for DN>300 Water Mains

Gear-operated butterfly valves for large-diameter water mains are rated by torque, pressure, leakage, and cycle life—metrics that directly impact system reliability and cost. Below are industry standards and typical performance data for DN300–DN1200 valves.

IV.A. Torque Requirements

Torque is the most critical metric for DN>300 valves, as insufficient torque causes disc binding (leading to seat damage) and excessive torque strains the gear system. Torque requirements increase with diameter and pressure:

|

Valve Diameter (DN)

|

Operating Pressure (Bar)

|

Required Torque (N·m)

|

Gear Ratio

|

Input Force (N)

|

|---|---|---|---|---|

|

300

|

10

|

350

|

5:1

|

70

|

|

600

|

10

|

1,200

|

10:1

|

120

|

|

1000

|

16

|

2,500

|

15:1

|

167

|

|

1200

|

16

|

3,200

|

20:1

|

160

|

All values meet API 609 requirements, which specify that input force must not exceed 200 N for ergonomic operation.

IV.B. Pressure and Temperature Ratings

Valves must withstand the maximum operating pressure (MOP) of the water main, plus a safety margin for pressure surges (common in large-diameter systems). Typical ratings:

-

Pressure Class: PN10 (10 bar), PN16 (16 bar), PN25 (25 bar). PN16 is the most common for municipal water mains (MOP 8–12 bar), while PN25 is used for industrial or high-rise building supply.

-

Temperature Range: -20°C to 120°C for EPDM seats (potable water), -40°C to 400°C for metal seats (industrial applications). A DN600 valve with EPDM seats maintains sealing integrity at 80°C (hot water mains) with no torque increase.

-

Pressure Surge Resistance: Valves are tested to 1.5x MOP for 30 minutes (hydrostatic test) with no deformation. A PN16 valve, for example, withstands 24 bar—protecting against surge events (e.g., sudden pump shutdown) that can spike pressure by 50%.

IV.C. Leakage and Shutoff Performance

Water main valves must minimize leakage to conserve water and prevent soil erosion (for buried mains). ANSI/FCI 70-2 classifies leakage, with Class VI (tight shutoff) required for potable water:

-

Class VI Leakage: ≤0.0001% of full flow. For a DN1000 valve with a flow rate of 10,000 cubic meters/hour, this equals ≤0.001 cubic meters/hour (1 liter/hour)—negligible for water mains.

-

Seat Testing: Valves are tested with 1.1x MOP air pressure (0.69 bar for gas testing) and checked for bubbles—no leakage is allowed for Class VI.

IV.D. Cycle Life and Durability

Large-diameter Butterfly Valves are rarely replaced (installation costs $20,000–$100,000 per valve), so long cycle life is critical:

-

Cycle Life: 100,000+ open-close cycles for elastomeric seats, 200,000+ cycles for metal seats. A municipal valve operated 10 times per month will last 833 years with metal seats—far exceeding the 50-year design life of most water mains.

-

Aging Testing: EPDM seats undergo 10,000 hours of accelerated aging (80°C, 5 mg/L chlorine) and retain 80% of original elasticity—ensuring 15+ years of service.

V. Installation and Maintenance Best Practices for DN>300 Valves

Improper installation of large-diameter gear-operated butterfly valves can increase torque requirements by 30%, reduce cycle life by 50%, and cause premature leakage. Below are step-by-step guidelines for safe, reliable installation and maintenance.

V.A. Pre-Installation Preparation

Preparation accounts for 40% of installation success, with two critical steps:

-

Pipe Alignment: Flanges must be parallel (error ≤0.5 mm) and coaxial (error ≤1.0 mm) to avoid binding the disc. A DN800 valve with 2 mm flange misalignment requires 1,560 N·m of torque (30% more than aligned valves). Use laser alignment tools for precision.

-

Valve Inspection: Check the gear box for water ingress (no lubricant discoloration), verify disc rotation (smooth 0–90° movement), and inspect seats for damage (no tears or cracks). Replace lubricant if the valve has been stored for >6 months (lubricant degrades over time).

V.B. Installation Procedures

Large-diameter valves (DN>600) require heavy equipment (cranes, flange spreaders) and a 2–3 person crew. Key steps:

-

Safe Lifting: Use a crane rated for 1.2x the valve’s weight (a DN1200 ductile iron valve weighs 800 kg—use a 960 kg-rated crane). Attach lifting slings to the valve body (not the gear box) to avoid damage.

-

Flange Mounting: Position the valve between pipe flanges with the disc fully open (reduces torque during installation). Use 4–6 alignment pins to hold the valve in place, then install high-tensile bolts (Grade 8.8) in a diagonal pattern. Torque bolts to 120–150 N·m (DN600) or 250–300 N·m (DN1200) per API 609.

-

Gear Box Positioning: Mount the gear box vertically (handwheel at waist height) for ergonomic operation—horizontal mounting increases input force by 20% and risks water ingress.

-

Post-Installation Testing: Conduct a hydrostatic test (1.5x MOP) and leakage test (Class VI) to verify performance. Rotate the valve through 3 full cycles to ensure smooth operation.

V.C. Maintenance Guidelines

Gear-operated valves require minimal maintenance, but periodic checks prevent costly failures:

-

Gear Box Lubrication: Replace lubricant every 2 years (potable water) or 1 year (wastewater). Use 500 mL of NSF H1 lubricant for DN300–DN600 valves, 1 L for DN800–DN1200 valves.

-

Seat Inspection: Inspect seats every 5 years for wear. For elastomeric seats, replace if compression set exceeds 30% (measured with a feeler gauge).

-

Torque Testing: Test operating torque annually—an increase of 20% indicates disc binding (e.g., debris buildup) or gear wear. Clean the valve internals or replace gears as needed.

-

Buried Valve Maintenance: For valves in underground boxes, inspect the box for water (pump out if flooded) and apply corrosion inhibitor to the gear box exterior every 3 years.

VI. Real-World Applications: Gear-Operated Valves in Large-Diameter Water Mains

Gear-operated butterfly valves are used in every segment of large-diameter water infrastructure, from municipal supply to industrial process systems. Below are three case studies highlighting their performance and cost savings.

VI.A. Municipal Potable Water Main (Los Angeles, CA, USA)

Project Details: 10 km DN1200 potable water main serving 500,000 residents; MOP 12 bar, chlorine residual 1.5 mg/L.

Challenge: Replace outdated gate valves (high torque, 20% leakage) with valves that reduce operation force and conserve water.

Solution: 15 gear-operated butterfly valves (DN1200, ductile iron body, EPDM seats, 20:1 gear ratio).

Results: Operation force reduced from 400 N to 160 N (60% decrease)—one worker can operate the valve vs. two for gate valves.Leakage reduced from 20% to Class VI (≤0.0001%)—saving 2,400 cubic meters of water per day.Maintenance costs cut by $50,000/year (no seat replacement needed for 10 years).ROI achieved in 2.5 years (total project cost $750,000).

VI.B. Wastewater Treatment Plant (Berlin, Germany)

Project Details: 500,000 cubic meters/day wastewater plant; DN600 valves controlling flow to secondary clarifiers (abrasive solids, 8% content).

Challenge: Manual valves failed after 2 years due to seat wear; replacement required plant shutdowns (cost $80,000/hour).

Solution: 8 gear-operated butterfly valves (DN600, 316L stainless steel body, Stellite 6 seats, 10:1 gear ratio).

Results: Cycle life extended to 200,000+ cycles—valves operating for 5 years with no seat replacement.No unplanned shutdowns (valves can be maintained without isolating the clarifier).Torque remained stable (1,200 N·m) with no binding (double-eccentric disc reduces friction).

VI.C. Industrial Cooling Water System (Shanghai, China)

Project Details: Steel mill cooling water system; DN800 valves controlling flow to blast furnaces (80°C, 16 bar, chloride content 1,000 mg/L).

Challenge: Pneumatic actuators failed due to high temperature; gear-operated valves needed corrosion resistance and high torque.

Solution: 12 gear-operated butterfly valves (DN800, duplex 2205 body, metal seats, 15:1 gear ratio).

Results: Corrosion rate ≤0.001 mm/year (no rust after 3 years).Withstands 80°C temperature with no torque increase (1,800 N·m maintained).Energy savings of 15% (full-port disc reduces pressure drop by 0.3 bar, cutting pump power use).

VII. TIANYU’s Custom Gear-Operated Butterfly Valves: Engineered for DN>300 Water Mains

TIANYU’s 40,000 m² manufacturing facility specializes in custom gear-operated butterfly valves for large-diameter water mains, combining precision engineering, global compliance, and application-specific design. Every valve is tailored to the customer’s pressure, media, and installation requirements—delivering performance that exceeds industry standards.

VII.A. Customization Capabilities

TIANYU offers end-to-end customization to meet unique water main needs:

-

Size Range: DN300–DN2000 (larger diameters available via special order), with wafer, lug, or flanged ends (ANSI B16.5, EN 1092-1).

-

Gear System Design: Custom gear ratios (5:1–25:1) to match torque requirements; bevel gears for tight spaces (e.g., underground valve boxes) or spur gears for high efficiency.

-

Material Selection: Ductile iron, 316L stainless steel, or duplex 2205 bodies; EPDM, NBR, or Stellite 6 seats—all tested for media compatibility.

-

Special Features: Locking handwheels (prevent unauthorized operation), position indicators (visual or electronic), and epoxy coatings (custom thickness for harsh environments).

VII.B. Quality Control and Compliance

TIANYU’s valves meet global standards for water mains, with rigorous testing at every manufacturing stage:

-

Material Testing: Spectral analysis for metal composition (e.g., 316L must contain 16–18% Cr), 1,000-hour salt spray testing for corrosion resistance.

-

Performance Testing: Hydrostatic pressure testing (1.5x MOP), torque testing (certified to ±5% accuracy), and Class VI leakage testing.

-

Compliance Certifications: NSF/ANSI 61 (potable water), API 609 (butterfly valves), WRAS (UK), and GB/T 17219 (China).

VII.C. Global Support and Service

Large-diameter valve installation and maintenance require local expertise—TIANYU provides:

-

On-Site Installation Support: Certified technicians assist with alignment, torqueing, and testing (available in 50+ countries).

-

Spare Parts Inventory: Global warehouses stock gear components, seats, and lubricants—next-day delivery for critical parts.

-

Warranty: 10-year warranty (industry average: 5 years) covering material defects, leakage, and gear system failure.

Gear-operated butterfly valves are the backbone of large-diameter water mains (DN>300), resolving the torque challenges of manual valves while delivering reliable, long-lasting performance. Their gear reduction systems, precision disc designs, and corrosion-resistant materials make them ideal for municipal, wastewater, and industrial applications—reducing water waste, lowering maintenance costs, and ensuring compliance with global safety standards.

TIANYU’s custom-engineered valves elevate this standard, with tailored designs that match the unique demands of every water main. From DN300 potable water lines to DN2000 industrial cooling systems, TIANYU delivers valves that combine torque efficiency, durability, and compliance—backed by global support and a 10-year warranty. For operators of large-diameter water infrastructure, TIANYU’s gear-operated butterfly valves represent a smart, long-term investment in reliability and performance.

TIANYU Custom Gear-Operated Butterfly Valve Advantages

TIANYU’s gear-operated butterfly valves (DN300–DN2000) excel in large-diameter water mains, with custom gear ratios (5:1–25:1) cutting input force by 90%. Made from ductile iron/316L/duplex 2205 and EPDM/Stellite seats, they meet NSF/ANSI 61 and API 609. Class VI leakage, 100,000+ cycles, and 10-year warranties ensure reliability. On-site support, global parts, and tailored coatings (epoxy) suit potable/wastewater/industrial use—delivering 15% energy savings and 40% lower maintenance costs.