In an era of increasingly scarce water resources and rising quality standards, water treatment plants serve as critical infrastructure for safeguarding this essential resource. Their operational efficiency and reliability are paramount. Flow control, being central to water treatment processes, directly impacts purification efficacy, energy consumption, and operational costs. Traditional flow control methods often fall short in meeting modern plants’ demands for automation, precision, and intelligence. Against this backdrop, Electric Actuated Ball Valves have emerged as the cornerstone of fluid control systems in the water treatment industry, combining robust performance with advanced automation capabilities.

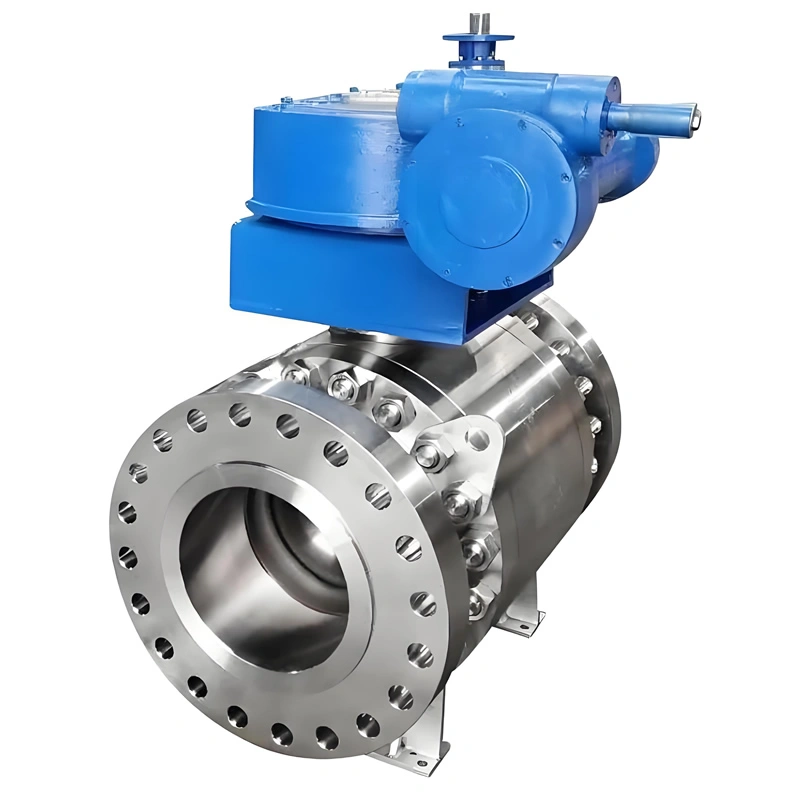

API 6D High-Pressure 900lb Flange-Type Forged Stainless Steel Full Port Floating Ball Valve

I. Core Principles and Technical Features of Electric Actuated Ball Valves

Electric actuated ball valves represent a sophisticated integration of precision mechanics, electric drive systems, and intelligent control technology—far more than a simple valve-motor assembly.

-

A. Essential Valve Body Structure

-

Rotating Ball Core: Features a precisely machined bore. Alignment with the pipeline axis permits full flow (open); a 90° rotation blocks flow completely (closed). This design achieves near-zero leakage.

-

Sealing Technology: Seats—constructed from advanced polymers (e.g., reinforced PTFE, RPTFE, PEEK) or metals (stainless steel, alloys)—ensure integrity. Polymer seats offer superior elasticity and chemical resistance; metal seats excel in high-temperature, high-pressure, and abrasive service. Spring-loaded or pressure-assisted designs guarantee reliability across pressure differentials (meeting ANSI/FCI 70-2 Class VI or higher).

-

Flow Path Optimization:

-

Full Port (Full Bore): Matches pipe ID, maximizing Cv value and minimizing pressure drop—ideal for raw water or sludge lines with solids.

-

Reduced Port: Lowers cost, size, and torque requirements where flow constraints allow.

-

-

Body Material Selection: Materials include cast iron (economical), ductile iron (strength), carbon steel (versatile), stainless steel (304/316L; corrosion resistance), duplex stainless steel (corrosion/erosion resistance), and alloy steel (high temp/pressure). TIANYU adheres to ASTM, DIN, and JIS standards.

-

-

B. Electric Actuator: The Drive and Control Hub

-

Drive Mechanism: A reversible synchronous motor drives a multi-stage gear reducer, converting high-speed/low-torque output into low-speed/high-torque rotation for valve operation.

-

Travel Control: Precision limit switches (mechanical or non-contact) halt the motor at preset open/close positions. Travel adjustment allows field calibration.

-

Torque Protection: Mechanical clutches or electronic sensors interrupt power and signal alarms if abnormal resistance (e.g., jamming, blockage) exceeds set limits, preventing damage.

-

Position Feedback: Potentiometers, encoders, or Hall-effect sensors provide real-time valve position (4-20mA or digital signal) for central control systems.

-

Control Modes:

-

On/Off: Drives valve to fully open or closed positions—standard for isolation.

-

Modulating: Uses a positioner board to interpret analog signals (e.g., 4-20mA) from PLCs/DCS, enabling precise 0-90° positioning for flow regulation (e.g., chemical dosing).

-

-

Protection & Certification: IP67/IP68 ratings ensure operation in wet or submerged environments. ATEX/IECEx (hazardous areas) and SIL2/SIL3 (safety systems) certifications address specific application risks.

-

-

C. Key Advantages of Electric Ball Valves

-

Exceptional Sealing: Metal seats achieve Class VI zero leakage; soft seats often exceed this standard, preventing water loss and contamination.

-

Minimal Flow Resistance: Full port designs approach straight-pipe resistance, reducing energy consumption significantly.

-

Rapid Operation: 90° quarter-turn actuation enables fast open/close cycles (seconds)—crucial for filter backwashing or emergency shutdowns.

-

Broad Media Compatibility: Proper material/seat selection handles water, wastewater, slurries, chemicals (acids, alkalis, chlorine, ozone), and steam.

-

High Reliability, Low Maintenance: Robust construction and minimal friction ensure long service life with less upkeep than Gate Valves or Globe Valves.

-

Automation Integration: Seamlessly interfaces with SCADA, DCS, and PLC systems—essential for unmanned plants and remote operations.

-

API 6D High-Pressure 900lb Flange-Type Forged Stainless Steel Full Port Floating Ball Valve

II. Application Analysis in Key Water Treatment Processes

Electric ball valves are integral across modern water treatment facilities:

-

A. Intake & Pretreatment

-

Raw Water Inlet Control: Large full-port valves manage main flow. Corrosion-resistant materials (316SS) and high IP ratings (IP68) combat natural water elements.

-

Screening Isolation: Valves isolate bar screens for maintenance. Wear-resistant seats handle debris.

-

Chemical Dosing Systems: Precision modulating valves control coagulants, flocculants, disinfectants (chlorine), and pH adjusters. Compatibility with aggressive chemicals (316L SS, Hastelloy, PTFE/FFKM seats) and precise control are vital.

-

Sedimentation/Clarification: Control inlet distribution, sludge drain, sludge recycle, and supernatant valves. Sludge valves require full-port design, abrasion-resistant seats (RPTFE/metal), and high torque.

-

-

B. Core Treatment (Filtration/Membrane Separation)

-

Filter Valve Battery (V-type, D-type, etc.):

-

Inlet/Drain Valves (On/Off): Enable rapid filter cycling.

-

Backwash Water/Air Valves (On/Off or Modulating): Full-port, low-pressure drop designs endure frequent, rapid cycling (dozens/hundreds daily). High reliability and torque are critical.

-

Surface Scour Valves (Modulating): Regulate wash intensity.

-

Control Integration: PLC-managed sequential and timing control relies on valve responsiveness and position feedback.

-

-

Membrane Systems (UF/MF/RO/NF):

-

Feed/Product/Concentrate Valves: On/Off or modulating. High cleanliness (Ra<0.8μm polish), low extractables (316L SS, EPDM/PTFE).

-

CIP Valves: Require extreme chemical resistance (316L SS/Hastelloy, FFKM seats) for acids, alkalis, oxidants.

-

Vent/Drain Valves (On/Off): For system startup/shutdown.

-

-

-

C. Disinfection & Clear Water Storage

-

Final Disinfection Dosing: Precision modulating valves control chlorine, chloramines, ClO₂, ozone, or UV precursor feed. Corrosion resistance remains key.

-

Clearwell Inlet/Outlet: Large On/Off valves manage storage tank filling/draining, often linked to level control. Long-term reliability is essential.

-

-

D. Sludge Handling

-

Sludge Transfer Lines: Full-port valves with abrasion-resistant seats/coatings (hardened SS, ceramic) and high torque handle viscous, solids-laden media (primary/secondary/chemical sludge).

-

Sludge Conditioning: Modulating valves control polymer (PAM) dosing for optimized dewatering.

-

-

E. Utilities & Auxiliary Systems

-

Cooling water control, instrument air isolation, plant drainage/overflow, and automated sampling valves.

-

III. Critical Selection Criteria for TIANYU Actuated Ball Valves

Proper selection is paramount to prevent failures:

ANSI CE DN200 Class 2500LB Stainless Steel F316 Flange-RTJ 3-Piece Worm Gear Trunnion Ball Valve

-

A. Process Parameters (Define Valve Body)

-

Media Type: Dictates corrosion/abrasion resistance and cleanliness (e.g., water, sludge, specific chemicals).

-

Temperature Range: Affects material strength and seal compatibility (e.g., PTFE cold flow).

-

Pressure Rating: Specify working pressure and required pressure class (ANSI 150#, PN40, etc.), considering potential water hammer.

-

Flow & Sizing: Pipe size (DN, NPS), need for Full Port (minimal ∆P, anti-clog) vs. Reduced Port. Verify Cv/Kv meets flow requirements. Modulating Valves: Select inherent flow characteristic (Quick Open, Linear, Equal %) for process stability.

-

End Connections: Flanged (RF, RTJ – ANSI/DIN/JIS), wafer, threaded (NPT, BSP), welded (SW, BW).

-

Leakage Class: Shutoff requirements (ANSI Class IV, V, VI; ISO 5208 A-D).

-

-

B. Actuator Selection (Match Valve & Duty)

-

Operation Mode: On/Off or Modulating (requires positioner).

-

Torque Requirement: Core sizing factor. Actuator output torque > (Valve max. torque @ max. ∆P) x Safety Factor (1.25-1.5). Consider high ∆P, viscosity, solids, tight seal, large size, or frequent cycling.

-

Speed: Time for 90° travel. Specify if fast operation (<10 sec for backwash) is needed.

-

Supply Voltage: Match plant power (AC 24V, 110V, 220V, 380V; DC 24V).

-

IP Rating: Minimum IP65; IP67/IP68 for washdown or submersion risk.

-

Explosion Protection: ATEX/IECEx for hazardous areas (ozone, chlorine).

-

Ambient Temperature: Affects electronics and grease.

-

Signals & Feedback:

-

On/Off: Open/Close commands, Open/Close limit switches, Torque alarm.

-

Modulating: Analog input (4-20mA) for control, analog output (4-20mA) for position. Communication protocols (HART, Modbus, Profibus, FF).

-

-

Manual Override: Essential for emergencies (handwheel, declutch).

-

-

C. Material Selection (Compatibility & Longevity)

-

Body/Ball: Cast Iron (GG25), Ductile Iron (GGG40), Carbon Steel (WCB), SS 304 (CF8), SS 316/316L (CF8M), Duplex (F51/F53), Alloy Steel (WC6/WC9), Special Alloys (Hastelloy, Ti). 304SS/316L SS dominate water treatment.

-

Stem: High-strength, corrosion/abrasion-resistant material (e.g., 316SS, 17-4PH).

-

Seat Materials:

-

Soft Seats: PTFE (std), RPTFE, PEEK (temp/abrasion), EPDM (hot water/chems), FKM/Viton (acids/solvents). PTFE/RPTFE/EPDM common.

-

Metal Seats: SS-SS, Stellite, Metal+Graphite—for high temp/pressure/abrasion/frequent cycling.

-

-

Stem Packing: PTFE V-rings, Graphite braid, Flexible graphite—consider temp, pressure, media, friction.

-

-

D. Standards & Certifications

-

Design/Manufacture: API 6D, ASME B16.34, ISO 17292, EN 1984.

-

Testing: API 598, ISO 5208, EN 12266-1.

-

Flanges: ASME B16.5, ASME B16.47, EN 1092-1.

-

Fire Safety: API 607/6FA, ISO 10497.

-

Functional Safety: IEC 61508/61511 (SIL2/SIL3).

-

Sanitary: 3-A, FDA (potable water contact).

-

Table: Key TIANYU Valve Selection Guide by Water Treatment Process

| Process Area | Typical Application | Valve Critical Requirements | Actuator Critical Requirements | Typical Material Set | Notes |

|---|---|---|---|---|---|

| Intake/Pretreatment | Raw Water Inlet/Outlet | Full Port, Corrosion Res., High IP | On/Off, High Torque, IP67/68 | 316SS Body/Ball, RPTFE Seat | Resist silt/algae |

| Chemical Dosing (Coag/Disinfect) | Small Bore, High Precision, High Chem. Resist. | Modulating, High Accuracy Pos., Fast Response | 316L SS, PTFE/PEEK/FFKM Seat | Chemical compatibility critical | |

| Filtration | Filter Backwash Water/Air | Full Port, Ultra-Low ∆P, Abrasion Resist., High Cycle Life | On/Off, High Torque, Very Fast (≤10s), Extreme Reliability | 316SS, Metal/RPTFE Seat | Plant-critical, failure impacts output |

| Filter Inlet/Drain | Full/Red Port, Reliable Shutoff | On/Off, Med. Speed | CF8M, RPTFE Seat | ||

| Surface Scour | Good Modulating Char. | Modulating, Med. Speed | CF8M, PTFE Seat | ||

| Membrane | RO/UF Feed/Product/Conc. | High Cleanliness (Mirror Finish), Low Extractables | On/Off or Modulating (High Precision) | 316L SS (Ra<0.8μm), EPDM/PTFE | Prevent membrane fouling |

| CIP Valves | Extreme Chemical Resistance | On/Off | 316L SS/Hastelloy C-276, FFKM Seat | Resist strong acids, bases, oxidizers | |

| Disinfection/Clear | Final Disinfectant Dosing | Small Bore, High Precision, High Chem. Resist. | Modulating, High Accuracy Pos. | 316L SS, FFKM/PEEK Seat | Precise residual control |

| Clearwell Inlet/Outlet | Large Bore, Reliable Shutoff | On/Off, High Torque | WCB/CF8 | High importance, long-term reliability | |

| Sludge Handling | Sludge Transfer | Full Port, Abrasion Resist. (Hardened/Coated), Anti-clog | On/Off, Very High Torque | Duplex F51 / C.S.+Wear Coat, Metal Seat | High solids, viscous media |

| Sludge Cond. Chemical Dosing | Chem/Abrasion Resist. | Modulating | CF8M, RPTFE/PEEK Seat |

IV. Installation, Commissioning & Maintenance: Ensuring Long-Term Reliability

Proper procedures are essential for optimal performance and longevity.

ANSI CE DN200 Class 2500LB Stainless Steel F316 Flange-RTJ 3-Piece Worm Gear Trunnion Ball Valve

-

A. Installation Best Practices

-

Clean Piping: Remove weld slag, debris, etc., before installation. Chemical cleaning/passivation may be needed for membrane systems.

-

Handling & Support: Lift using valve body lugs—never by actuator or stem. Support large valves/piping to prevent stress on flanges/stem.

-

Alignment & Bolting: Ensure flange parallelism. Use correct bolts, gaskets, and cross-tightening sequence to specified torque.

-

Flow Direction: Most ball valves are bidirectional. Verify specific design requirements.

-

Actuator Orientation: Ensure accessibility, visibility, ventilation, and protection from water, vibration, and heat.

-

Electrical Connection: Qualified personnel only. Use proper cable, secure terminations, seal entries (cable glands), and ground reliably.

-

-

B. Commissioning Procedure

-

Mechanical Check: Manual operation (via handwheel) for smooth, unrestricted rotation. Check bolt tightness.

-

Travel Setting (Limit Switches):

-

Manually move valve to Fully Closed.

-

Adjust Close Limit Switch until it triggers precisely at closed position. Secure.

-

Manually move valve to Fully Open.

-

Adjust Open Limit Switch until it triggers precisely. Secure.

-

-

Torque Setting (Torque Switch): Set trip value slightly above normal operating torque (refer to manual). Tip: Temporarily increase setting during initial setup to avoid nuisance trips; fine-tune after confirming free movement.

-

Electrical Function Test:

-

Verify correct Open/Close direction (swap motor phases if reversed).

-

Confirm valve stops accurately at limits.

-

Simulate jamming—test torque trip and alarm signal.

-

Verify Open/Close/Torque fault signals to control system.

-

Modulating Valves: Calibrate positioner (zero/span); test signal correspondence (Input 4-20mA ↔ Valve 0-90° ↔ Output 4-20mA).

-

-

System Integration Test: Verify correct operation within PLC/DCS, including interlocks (e.g., pump/valve sequences, backwash timing).

API608 DN300 F304L 3-Piece Stainless Steel High Pressure 900lb Flanged Gearbox Steam Rated High Temp Trunnion Mounted Ball Valve

-

-

C. Preventive Maintenance Program (PPM)

A disciplined PPM is crucial:-

Routine Inspection:

-

Visual checks for leaks (stem, flanges, actuator).

-

Listen for abnormal noise/vibration.

-

Observe smooth operation and proper seating.

-

Check electrical integrity (conduit seals, cable condition).

-

Log cycle counts (especially high-frequency valves).

-

-

Scheduled Maintenance:

-

Actuator:

-

Lubrication: Replace gearbox grease per manual (typically 1-2 years/cycles). Use specified high-temp lithium/synthetic grease. Clean old grease thoroughly.

-

Electrical: Check terminations tightness; clean dust/moisture (bi-annually). Measure motor insulation resistance (megger).

-

Seals: Inspect housing seals; replace if aged.

-

-

Valve Body:

-

Stem Packing Adjustment: Slight weeping is normal lubrication. Gently tighten gland nuts (e.g., 1/6 turn) if needed. Avoid over-tightening—causes friction and damage. Replace packing if adjustment fails or leakage is severe.

-

Bolt Re-torquing: Check flange bolts (post-commissioning, outages)—re-torque to spec (hot retightening may be needed).

-

Exercise Infrequently Operated Valves: Cycle monthly to prevent seat sticking (e.g., clearwell valves).

-

-

-

Troubleshooting:

-

Jamming/No Movement: Check for obstruction, pipe stress, tight packing, bearing failure, insufficient torque, or actuator fault.

-

Leaks:

-

Stem Leak: Adjust/replace packing.

-

Seat Leak (Internal): Damaged seat, debris, seat wear, incorrect travel/torque. Requires disassembly.

-

Flange Leak: Check torque, gasket condition, flange face.

-

-

Actuator Unresponsive: Verify power, fuses, control signals, wiring, motor, limit/torque switch status.

-

Actuator Torque Trip: Investigate jamming, excessive ∆P, low torque setting, actuator fault. Never increase setting without resolving root cause.

-

Incorrect Position Feedback (Modulating): Check positioner calibration, feedback linkage, valve sticking.

-

-

V. Smart Trends and TIANYU Innovations

Intelligent water treatment plants are transforming valve management:

API608 DN300 F304L 3-Piece Stainless Steel High Pressure 900lb Flanged Gearbox Steam Rated High Temp Trunnion Mounted Ball Valve

-

A. Intelligent Electric Actuators

-

Integrated Diagnostics: Monitor parameters: cycles, running hours, stroke time, operating/trip torque, motor current/temperature, ambient temperature, vibration.

-

Predictive Maintenance (PdM): Analyze data trends for early warnings:

-

Rising torque/current → potential jamming or media change.

-

Longer stroke time → lubrication degradation or wear.

-

High motor temp → impending failure.

-

Abnormal vibration → bearing damage.

-

Generate alerts (“Lubrication Due,” “Seat Wear Advisory”).

-

-

Condition Monitoring Interfaces: Transmit data via HART, Profibus, Modbus, FF, or IO-Link Wireless to CMMS/EAM/cloud platforms.

-

Remote Configuration/Diagnostics: Use HMI, laptop, or network for setup, calibration, troubleshooting, and firmware updates.

-

-

B. IoT & Cloud Platforms

-

Centralized Asset Management: Unified platform for all valves—electronic records (serial #, location, manuals, maintenance history, spare parts).

-

Performance Analytics: Identify fleet-wide trends, optimize maintenance schedules, compare reliability, inform spare parts strategy.

-

Energy Optimization: Analyze valve position/pressure drop vs. pump energy to find savings (e.g., closing unnecessary valves, optimizing control).

-

Mobile Applications: Technicians receive alerts, view real-time data/instructions, and log work via tablets/phones.

-

-

C. TIANYU’s Continuous Innovation

-

Low-Power Design: Optimized mechanics for energy-efficient operation.

-

Advanced Sealing Solutions: R&D in composite seats (e.g., carbon-filled PEEK, specialty elastomers) for extreme environments.

-

Modularity & Serviceability: Quick component replacement minimizes downtime.

-

Enhanced Cybersecurity: Hardware/software protections (secure boot, encryption, access control) for connected actuators.

-

Water Treatment-Specific Solutions: Valves and actuators engineered for high-cycle, abrasive, corrosive, high-reliability demands.

-

DN200 Class2500 Stainless Steel Flanged End Electric Top-Entry Trunnion Mounted Ball Valves

Electric actuated ball valves have evolved from basic isolation devices into the backbone of efficient, precise, and intelligent flow control within modern water treatment plants. Their superior sealing, minimal resistance, rapid response, and seamless automation integration make them indispensable from intake to effluent.

Mastering their technology, selecting the right TIANYU Ball Valves Manufacturer for each application, and adhering to rigorous installation, commissioning, and maintenance protocols are fundamental to maximizing plant performance and reliability. As smart technologies and IoT integration deepen, these valves are evolving from passive components into intelligent data sources, laying the foundation for unmanned operations, predictive maintenance, and true plant-wide intelligence. For water professionals committed to sustainable resource management and operational excellence, leveraging high-performance, reliable electric actuated ball valves is not just an option—it’s a strategic imperative.