I. Introduction

II. Important Attributes and Specification Parameters

(I) Temperature Rating

(II) Pressure Rating

(III) Caliber Size

(IV) Connection Methods

III. Feature Description

(I) Excellent Low-Temperature Adaptability

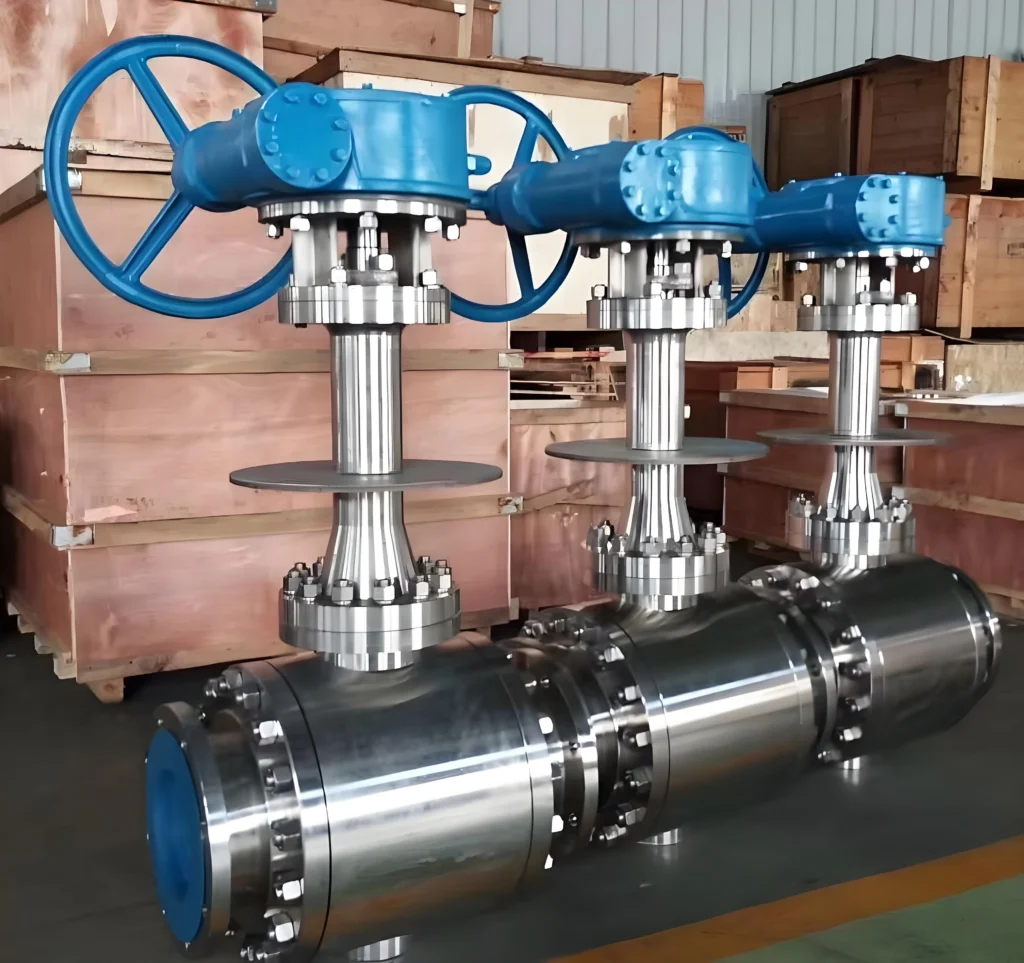

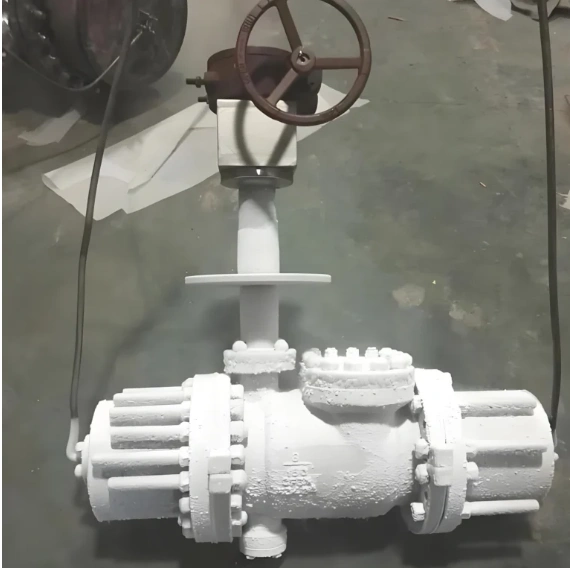

- Selection of Special Materials: Key components such as the valve body, ball, and valve stem are made of special steels that can maintain good mechanical properties in low-temperature environments, such as nickel-containing low-temperature steel. This type of steel has undergone strict screening and testing. At a low temperature of -196°C, it still has high strength and toughness, effectively preventing material cold brittleness, and ensuring the structural integrity and operational reliability of the valve.

- Low-Temperature Sealing Technology: Equipped with a sealing structure and sealing materials specially designed for low-temperature working conditions. The sealing materials usually include low-temperature resistant polytetrafluoroethylene (PTFE) or modified rubber. Under extremely cold conditions, these materials can maintain good flexibility and elasticity, closely fit the sealing surface, achieve reliable sealing, prevent LNG leakage, and ensure the safe operation of the system.

(II) Precise Flow Control

- Optimization of Ball Structure: The ball is designed precisely, with extremely high matching accuracy between the center of the ball and the valve seat. The diameter of the through-hole on the ball has good adaptability to the inner diameter of the pipeline. When the valve is opened, LNG can pass through smoothly, with uniform and stable flow; when closed, the ball closely fits the valve seat, with a significant effect of cutting off the fluid. It can accurately regulate and control the LNG flow, meeting the strict requirements for flow in different process links.

- Operational Flexibility: The valve is easy to operate, and it only needs to rotate 90° to switch between fully open and fully closed states. For manual operation, the handle is designed in accordance with ergonomic principles, with moderate operating torque, facilitating easy operation by workers; if equipped with electric or pneumatic actuators, remote automatic control can be realized, with rapid response, which can accurately adjust the valve opening according to system instructions and efficiently control the LNG flow.

(III) High Reliability and Long Service Life

- Robust Structural Design: The overall structure is compact and reasonable, fully considering the complex working conditions such as pressure, temperature, and fluid impact in LNG applications. The wall thickness of the valve body is accurately calculated and designed, with sufficient strength to resist external pressure and internal medium impact; the internal components are scientifically arranged and firmly connected, reducing the risk of component loosening and damage caused by vibration and impact, and ensuring long-term stable operation of the valve.

- Strict Quality Inspection: In the production process, TIANYU implements strict quality inspection standards. Each cryogenic ball valve must undergo multiple inspection procedures before leaving the factory, including low-temperature performance testing, pressure testing, and sealing performance testing. Through rigorous testing by simulating actual working conditions, it is ensured that all performance indicators of the valve meet or even exceed industry standards, thereby guaranteeing high reliability and long service life of the valve in LNG applications.

IV. Manufacturing Process

(I) Material Selection and Treatment

- Procurement of High-Quality Raw Materials: TIANYU has established long-term and stable cooperative relationships with well-known domestic and foreign steel suppliers to ensure the acquisition of high-quality low-temperature steel raw materials. Each batch of materials must undergo strict quality inspection when entering the factory, including chemical composition analysis and mechanical property testing. Only materials that fully meet the standards can enter the production process, ensuring product quality from the source.

- Low-Temperature Pretreatment of Materials: To further improve the performance stability of materials in low-temperature environments, the materials of key components will undergo special low-temperature pretreatment processes before processing. For example, the steel is subjected to deep cooling treatment, placed in a liquid nitrogen environment (-196°C) for a certain period of time, making the internal structure of the material more uniform and refined, thereby improving the strength, toughness, and fatigue resistance of the material, and enhancing the durability of the valve in LNG low-temperature working conditions.

(II) Precision Machining Process

- Application of Advanced Machining Equipment: The production workshop is equipped with a series of advanced CNC machining equipment, such as high-precision CNC lathes, milling machines, and grinders. These equipment have a high degree of automation and machining accuracy, and can perform precision machining on components such as the valve body, ball, and valve stem in strict accordance with the design drawings, ensuring that the dimensional accuracy of each component is controlled within a very small tolerance range, meeting the high-precision assembly requirements of the valve, and improving the overall performance of the valve.

- Ball Grinding and Polishing: As the core component of the valve, the surface quality of the ball is crucial to the sealing performance and flow control effect. TIANYU adopts professional ball grinding and polishing processes. Through multiple grinding procedures, using abrasive materials of different particle sizes, the surface roughness of the ball is gradually reduced to achieve mirror finish. The ball after fine grinding and polishing fits more closely with the valve seat, effectively reducing leakage and improving the sealing performance and service life of the valve.

(III) Welding and Assembly Processes

- Automatic Welding Technology: For valve components with welded connections, TIANYU uses advanced automatic welding equipment and processes. The welding process is precisely controlled by a computer to ensure stable parameters such as welding current, voltage, and welding speed, resulting in uniform, firm, and reliable welds. At the same time, before and after welding, strict non-destructive testing is performed on the welded parts, such as ultrasonic flaw detection and radiographic inspection, to timely detect and eliminate welding defects, ensuring the strength and sealing of the welded joints.

- High-Precision Assembly Process: The assembly process follows strict operating procedures and quality control standards. All components must undergo cleaning and rust-proof treatment before assembly to ensure no impurities, oil stains, etc., that affect assembly quality. During the assembly process, professional assembly tools and equipment are used, and assembly is carried out in accordance with precise assembly sequences and tolerance requirements. Each assembly step is strictly inspected and recorded to ensure high assembly accuracy and tight fitting of all valve components, and the overall performance meets the design requirements.

(IV) Quality Inspection and Certification

- Comprehensive Quality Inspection System: A sound quality inspection system has been established, covering all links such as raw material inspection, process inspection, and finished product inspection. In addition to conventional dimensional measurement and appearance inspection, advanced testing equipment and technologies are used to conduct comprehensive testing on the performance of the valve. For example, the low-temperature performance test device is used to simulate the -196°C low-temperature environment to conduct low-temperature operation tests and low-temperature sealing performance tests on the valve; pressure testing equipment is used to conduct high-pressure strength tests and sealing performance tests on the valve to ensure that the valve can operate reliably under various working conditions.

- Acquisition of Authoritative Certifications: TIANYU cryogenic ball valves actively participate in the certification audits of domestic and foreign authoritative certification bodies, and have successively obtained certifications such as ISO quality management system certification, API (American Petroleum Institute) certification, and CE (European Conformity) certification. These certifications are not only a high recognition of product quality and performance but also provide a strong guarantee for the wide application of products in domestic and foreign markets, demonstrating TIANYU’s professional strength and excellent quality in the field of cryogenic ball valve manufacturing.

V. Product Advantages

(I) Excellent Performance

- Stable Low-Temperature Performance: In the extreme low-temperature environment of -196°C, TIANYU cryogenic ball valves have stable material performance, reliable sealing, and flexible operation. They can continuously and stably control LNG fluid, providing a solid guarantee for the safe operation of all links in the LNG industry chain, and effectively reducing the risk of production interruption caused by valve failures.

- Strong Pressure-Bearing Capacity: The high pressure rating of Class 1500 enables the valve to work normally under high-pressure working conditions. Whether in the high-pressure reaction link during LNG production or the high-pressure pumping stage during long-distance transportation, it can cope with ease, ensuring system pressure stability and preventing safety accidents caused by pressure fluctuations.

(II) Safety and Reliability

- Multiple Safety Designs: The valve has safety design features such as fire resistance and anti-static. The fire-resistant design ensures that the valve can maintain structural integrity in case of accidents such as fires, preventing LNG leakage from causing more serious safety accidents; the anti-static design effectively eliminates static accumulation generated by fluid flow, avoiding dangers such as fires and explosions caused by static electricity, and comprehensively ensuring the safe operation of the LNG system.

- High Sealing Performance: Adopting advanced sealing structures and high-quality sealing materials, after strict sealing performance tests, the valve has excellent sealing performance, which can effectively prevent LNG leakage. This not only protects the environment and reduces energy waste but also, more importantly, reduces potential safety hazards caused by leakage, ensuring the safety of personnel and equipment.

(III) Convenient Maintenance

- Reasonable Structural Design: The overall structure of the valve is compact and reasonable, and each component is easy to disassemble and install. During maintenance and overhaul, workers can conveniently inspect, clean, and replace the internal components of the valve, greatly shortening the maintenance time, improving maintenance efficiency, and reducing equipment downtime and maintenance costs.

- Strong Universality of Components: TIANYU pays attention to the standardization and universality design of product components. Most components of cryogenic ball valves of the same specification series can be interchanged. This enables quick access to suitable spare parts when replacing components, reducing the types and quantities of spare parts inventory, lowering the operating costs of enterprises, and improving the timeliness of equipment maintenance.

(IV) High Cost-Effectiveness

- Long Service Life: With excellent product performance, reliable quality, and strict manufacturing processes, TIANYU cryogenic ball valves have a long service life. Under normal use and maintenance conditions, the valve can operate stably for a long time, reducing equipment procurement costs, installation costs, and economic losses caused by production interruption due to frequent valve replacement, bringing significant long-term economic benefits to users.

- High Efficiency and Energy Saving: The precise flow control performance of the valve can optimize the operation efficiency of the LNG system and reduce unnecessary energy consumption. On the premise of meeting the needs of the production process, it realizes the rational use of energy, reduces the energy costs of enterprises, conforms to the current development trend of energy conservation and environmental protection, and enhances the comprehensive competitiveness of enterprises.

VI. Product Working Condition Applications

(I) LNG Production Link

- Natural Gas Liquefaction Plant: In natural gas liquefaction plants, TIANYU Cryogenic Ball Valves are used to control the flow and pressure of natural gas during the liquefaction process. In key process steps such as cooling and liquefaction, the valve can accurately adjust the flow rate and direction of natural gas to ensure the stable and efficient progress of the liquefaction process. For example, installing Cryogenic Ball Valves on the inlet and outlet pipelines of low-temperature heat exchangers can quickly and accurately control the flow of natural gas according to process requirements, realize precise control of liquefaction temperature and pressure, and improve liquefaction efficiency and product quality.

- Feed Gas Pretreatment System: Before the feed gas enters the liquefaction device, it needs to be pretreated to remove impurities, moisture, etc. TIANYU Cryogenic Ball Valves play an important role in cutting off and regulating in the pretreatment system. They can be used to control the transportation, distribution, and inlet and outlet flows of each treatment unit of the feed gas, ensuring the smooth progress of the pretreatment process and providing high-quality raw materials for subsequent natural gas liquefaction.

(II) LNG Storage Link

- LNG Storage Tank Inlet and Outlet: The LNG storage tank is a key equipment for storing LNG. The TIANYU Cryogenic Ball Valves installed on the inlet and outlet pipelines of the storage tank are used to control the inlet and outlet flow of LNG. During the storage tank filling process, the valve can accurately adjust the filling speed according to the changes in the storage tank liquid level and pressure, preventing excessive filling from causing excessive pressure or liquid level overflow in the storage tank; when unloading the storage tank, the valve can be opened and closed quickly and reliably to ensure that LNG can be safely and smoothly transported to downstream users or transportation equipment.

- Storage Tank Pressure Regulation System: To maintain the pressure stability in the LNG storage tank, a pressure regulation system is usually set up. As an important part of the pressure regulation system, TIANYU Cryogenic Ball Valves can automatically or manually adjust the valve opening according to the pressure changes in the storage tank, control the discharge or recovery of LNG boil-off gas (BOG), keep the storage tank pressure within a safe range, and prevent storage tank damage or safety accidents caused by abnormal pressure.

(III) LNG Transportation Link

- LNG Tanker Loading and Unloading System: On the loading and unloading connection pipelines between LNG tankers and filling stations and receiving stations, TIANYU cryogenic ball valves are used to control the loading and unloading operations of LNG. The valve has the function of quick opening and closing, which can realize efficient loading and unloading of LNG in a short time, while ensuring the sealing and safety during the loading and unloading process and preventing LNG leakage. In addition, the valve is easy to operate and can adapt to the needs of tanker loading and unloading operations under different environmental conditions.

- LNG Ship Conveying System: For ships transporting LNG at sea, TIANYU cryogenic ball valves are widely used in their conveying systems. These valves are used to control the flow of LNG between the ship’s storage tanks and the conveying pipelines, as well as the unloading operations between the ship and the receiving station. During the ship’s navigation, the valve needs to withstand harsh marine environmental conditions such as low temperature, humidity, and vibration. With its excellent performance and reliable quality, TIANYU cryogenic ball valves can ensure the stable operation of the LNG conveying system under complex working conditions, ensuring the safety and efficiency of LNG maritime transportation.

(IV) LNG Application Link

- LNG Filling Station: In LNG filling stations, TIANYU Cryogenic Ball Valves are used to control the transportation process of LNG from the storage tank to the filling gun. The valve can accurately adjust the flow of LNG according to the filling demand to achieve rapid and safe filling. At the same time, the high sealing performance of the valve effectively prevents LNG leakage during the filling process, ensuring the safety of workers and vehicles at the filling station. In addition, through integration with the automatic control system of the filling station, the Cryogenic Ball Valves can realize remote monitoring and operation, improving the operation and management efficiency of the filling station.

- Industrial User Terminals: Some industrial users, such as glass manufacturing and ceramic production industries, use LNG as fuel. In the LNG supply systems of these industrial users, TIANYU cryogenic ball valves are used to control the flow and pressure of LNG to meet the needs of different production processes for gas. The precise control performance of the valve can ensure stable gas supply during industrial production, improve production efficiency and product quality, and reduce energy consumption and production costs.

TIANYU’s Cryogenic Ball Valves specially built for LNG applications (-196°C, Class 1500) rely on their excellent important attributes and specification parameters, such as the working temperature adapting to extremely low temperatures, the pressure rating bearing high pressure, various calibers and connection methods; unique features including excellent low-temperature adaptability, precise flow control, high reliability, and long service life; advanced manufacturing processes, from material selection and treatment to precision machining, welding and assembly, as well as strict quality inspection and certification; significant product advantages covering excellent performance, safety and reliability, convenient maintenance, and high cost-effectiveness; and wide product working condition applications throughout the entire industrial chain of LNG production, storage, transportation, and application. This Cryogenic Ball Valves has become an indispensable key equipment in the LNG industry, providing solid support for ensuring the safe, stable, and efficient operation of LNG systems. Whether as a core control component in new projects or replacing existing valves in the upgrading and transformation of existing systems, TIANYU cryogenic ball valves can meet the diverse needs of customers with their excellent quality and contribute to the vigorous development of the LNG industry.