I. Introduction

II. Basic Principles of Valve Symbols

A. Governing Industry Standards for Valve Symbols

- ASME Y14.35M: Developed by the American Society of Mechanical Engineers, this standard defines graphical symbols for fluid power systems, including valves. Widely used in North America, it establishes the basic structure of valve symbols, covering valve bodies, actuation, and flow paths.

- ISO 128: The International Organization for Standardization’s standard for technical drawings, with Part 24 focusing on valve symbols. Adopted globally, it is critical for international projects, featuring simple, recognizable symbols compatible with digital drafting tools.

- API Standards (API 600, API 608, API 609): While primarily focusing on valve design and testing, API standards reference valve symbol conventions to align specifications with technical drawings. TIANYU’s API-compliant valves feature symbols consistent with these conventions.

- IEC 60617: Developed by the International Electrotechnical Commission, this standard defines symbols for electric valve actuators and control systems, often used with ASME Y14.35M and ISO 128 for comprehensive P&IDs.

B. Core Objectives of Valve Symbols

- Standardization: Providing a common language to eliminate ambiguity, critical for international projects with language barriers.

- Clarity & Efficiency: Simplifying complex valve configurations into easy-to-interpret graphics, saving time in design, installation, and maintenance.

- Accuracy in Procurement & Installation: Conveying precise specifications for procurement teams and guiding technicians during installation.

- Safety & Compliance: Communicating critical safety information, such as flow direction and fail-safe actuation, ensuring compliance with regulations like CE PED 2014/68/EU.

C. Key Principles for Interpreting Valve Symbols

- Simplicity Over Detail: Symbols focus on critical information (type, actuation, flow) rather than mechanical details.

- Consistency in Core Elements: All symbols share common components (valve body, flow arrows, actuation icons), enabling interpretation of unfamiliar symbols.

- Context Matters: Symbols must be interpreted alongside project specifications, as the same symbol may indicate different valve features in different industries.

III. Core Components of Valve Symbols

A. Valve Body Symbol (Core Element)

- Piping Connections: Straight horizontal or vertical lines indicating the inlet, outlet, and valve position in the pipeline.

- Body Shape: A central shape distinguishing valve type:

- Linear Valves (Gate, Globe, Check): Rectangular or square central shape, indicating linear movement of internal mechanisms.

- Rotary Valves (Ball, Butterfly, Plug): Circular or oval central shape, indicating rotational movement of internal mechanisms.

- Flow Path: Dashed or solid lines inside the body indicating flow direction and port size (full or reduced).

B. Valve Internal Mechanism Symbol

- Ball Valve: Small circle (ball) with a straight line (full-port) or dashed line (reduced-port) through it.

- Butterfly Valve: Straight line (disc) across the circular body; offset for double/triple eccentric designs (TIANYU’s flagship butterfly valves).

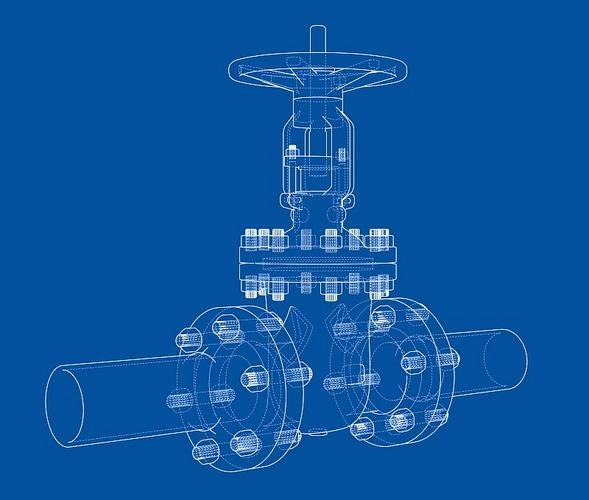

- Gate Valve: Vertical/horizontal rectangle (gate); solid for rising stem, dashed for non-rising stem.

- Globe Valve: Semicircle (disc) perpendicular to the flow path.

- Check Valve: One-way arrow or hinged disc (swing) / vertical disc (lift) / small circle (ball).

- Plug Valve: Triangle or diamond (plug) with a line indicating the bore.

- Relief Valve: Coiled line (spring) inside the body.

C. Actuation Method Symbol

- Manual Actuation: Handwheel (circle with spokes), turbine (circle with gear), or lever (straight line).

- Pneumatic Actuation: Two rectangles (double-acting) or one rectangle + coiled line (spring-return, with “NC”/”NO” for fail-safe position).

- Electric Actuation: Small square (motor); with “REG” for regulating, “SCADA” for remote control.

- Hydraulic Actuation: Circle with “H” inside.

D. Flow Direction & Function Symbols

- Flow Direction: One-way arrow (unidirectional, e.g., check valves) or two arrows (bidirectional, e.g., ball/butterfly valves).

- Normally Open (NO)/Normally Closed (NC): Labels indicating valve position when not actuated.

- Function Labels: “R” (relief), “REG” (regulating) for specialized valves.

E. Additional Feature Symbols

- Soft Seal: “S” (PTFE/EPDM)

- Metal Hard Seal: “M” (Stellite overlay)

- Fire-Safe: Flame symbol (API 607 compliant)

- Anti-Blowout Stem: “ABS”

- Fugitive Emissions: “FE” (ISO 15848-1 compliant)

- Sour Service: “H₂S” (NACE MR0175 compliant)

IV. Common Valve Type Symbols & Their Interpretations

A. Ball Valve Symbols

- Body Symbol: Circular/oval with piping connections on either side.

- Internal Mechanism: Small circle (ball) with a straight (full-port) or dashed (reduced-port) line.

- Variations:

- Floating Ball: Centered ball symbol (no supports), for small diameters.

- Trunnion-Mounted: Ball with top/bottom lines (trunnions), for high-pressure/large-diameter valves (TIANYU’s API 608-certified models).

- 3PC Ball: Body divided into three sections, indicating disassemblable design.

- Actuation: Handwheel, turbine, pneumatic, or electric symbols.

B. Butterfly Valve Symbols

- Body Symbol: Large circular shape with piping connections.

- Internal Mechanism: Straight line (disc); offset for double eccentric (TIANYU’s API 609-compliant flagship) or angled for triple eccentric.

- Seal Symbols: “S” (soft seal) or “M” (metal seal).

- Actuation: Handwheel, turbine, pneumatic (spring-return for hazardous environments), or electric.

C. Gate Valve Symbols

- Body Symbol: Rectangular/square with piping connections.

- Internal Mechanism: Vertical/horizontal rectangle (gate); solid (rising stem) or dashed (non-rising stem).

- Stem Symbol: Straight line (rising) or coiled line (non-rising).

- Actuation: Handwheel, turbine, or hydraulic (large diameters).

D. Globe Valve Symbols

- Body Symbol: Rectangular with side (inlet) and top/bottom (outlet) connections.

- Internal Mechanism: Semicircle (disc) perpendicular to flow.

- Flow Direction: One-way arrow toward the disc.

- Actuation: Handwheel, electric (regulating), or pneumatic.

E. Check Valve Symbols

- Body Symbol: Rectangular (linear) or circular (rotary).

- Internal Mechanism: Hinged disc (swing), vertical disc (lift), or small circle (ball).

- Flow Direction: One-way arrow (critical for installation).

- No Actuation Symbol: Automatic operation.

F. Plug Valve Symbols

- Body Symbol: Circular/oval with piping connections.

- Internal Mechanism: Triangle/diamond (plug) with a line indicating the bore.

- Actuation: Handwheel, lever, or pneumatic.

- Seal Symbols: “L” (lubricated) or “NL” (non-lubricated).

G. Relief Valve Symbols

- Body Symbol: Circular/rectangular with bottom (inlet) and top (outlet) connections.

- Internal Mechanism: Coiled line (spring).

- Flow Direction: One-way arrow upward.

- Pressure Set Point: Number (e.g., “PN25”) indicating opening pressure.

V. Valve Actuation Symbols in Detail

A. Manual Actuation Symbols

- Handwheel: Circle with 4–6 spokes, for small-to-medium valves (TIANYU’s manual ball/butterfly valves, DN15–DN300).

- Lever: Straight line perpendicular to flow, for small valves (TIANYU’s DN15–DN50 ball/butterfly valves) requiring fast on-off cycles.

- Turbine Manual: Circle with gear inside, for large-diameter valves (TIANYU’s DN500+ trunnion-mounted ball/double offset butterfly valves) requiring torque reduction.

B. Pneumatic Actuation Symbols

- Double-Acting: Two rectangles (air cylinders), for systems without fail-safe requirements (TIANYU’s double-acting pneumatic valves).

- Spring-Return: One rectangle + coiled spring, with “NC” (fail-closed) or “NO” (fail-open) labels, for hazardous environments (TIANYU’s emergency shut-off valves).

C. Electric Actuation Symbols

- On-Off Electric: Small square (motor), for remote/hard-to-reach installations (TIANYU’s electric ball/butterfly valves).

- Regulating Electric: Square with “REG” inside, for precise flow/pressure control (TIANYU’s electric globe valves).

- SCADA-Compatible: Square with “SCADA” label, for integration into smart systems (TIANYU’s electric trunnion-mounted ball/double offset butterfly valves).

D. Hydraulic Actuation Symbols

- Hydraulic: Circle with “H” inside, for large-diameter gate valves (TIANYU’s DN1000+ hydraulic gate valves) in mining/metallurgy.

VI. Application of Valve Symbols in Industrial Drawings

A. Piping and Instrumentation Diagrams (P&IDs)

- They indicate valve location, type, actuation, flow direction, and connections to other components.

- TIANYU provides P&ID-compatible symbols for all products, ensuring easy integration into client drawings.

- Consistency: Use one standard (ASME Y14.35M for North America, ISO 128 for international projects) throughout.

- Labeling: Unique identifiers (e.g., “V-101”) for each valve.

- Clarity: Avoid overcrowding; use zoomed-in details for complex areas.

- Legend: Define all symbols used, especially for specialized valves (e.g., TIANYU’s double offset butterfly valves).

B. Other Industrial Drawings

- Piping Layout Drawings: Simplified valve symbols indicating position and pipeline connections.

- Valve Assembly Drawings: Basic symbols highlighting valve type and actuation, with detailed internal components.

- Maintenance Manuals: Symbols guiding technicians through disassembly/reassembly (TIANYU’s manuals use symbols to label key parts).

VII. Common Mistakes in Interpreting Valve Symbols & How to Avoid Them

A. Mistake 1: Confusing Ball vs. Butterfly Valve Symbols

A. Mistake 1: Confusing Ball vs. Butterfly Valve Symbols

Mistake: Mixing up rotary valve symbols due to similar circular bodies.

Solution: Focus on internal mechanisms—ball valves have a small circle (ball), butterfly valves have a straight line (disc). TIANYU’s tip: Look for offsets (butterfly) or port lines (ball).

B. Mistake 2: Ignoring Pneumatic Actuation Variations

Mistake: Confusing double-acting and spring-return pneumatic symbols.

Solution: Double-acting has two rectangles; spring-return has one rectangle + spring, with “NC”/”NO” labels. TIANYU’s tip: Align with safety requirements (spring-return for hazardous environments).

C. Mistake 3: Misinterpreting Flow Direction

Mistake: Installing valves backwards (e.g., check valves).

Solution: Follow arrows—one-way for check valves, two-way for ball/butterfly valves. TIANYU’s tip: Valve bodies have flow arrows matching symbols.

D. Mistake 4: Overlooking Additional Feature Symbols

Mistake: Missing seal type or safety symbols, leading to incompatible valves.

Solution: Check for “S”/”M” (seal), flame (fire-safe), or “FE” (fugitive emissions) symbols. TIANYU’s tip: Cross-reference with datasheets.

E. Mistake 5: Using Outdated Symbols

Mistake: Using non-standard/outdated symbols, causing miscommunication.

Solution: Use current standards (ASME Y14.35M-2007, ISO 128-24:2021); update old drawings. TIANYU’s tip: Request updated symbols for TIANYU products.