III. Feature Description

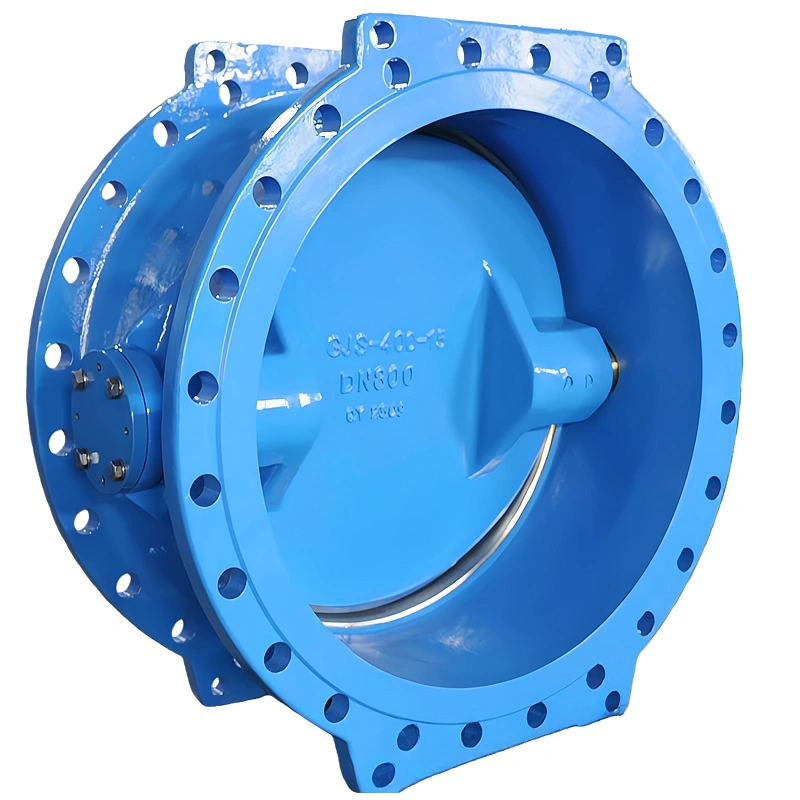

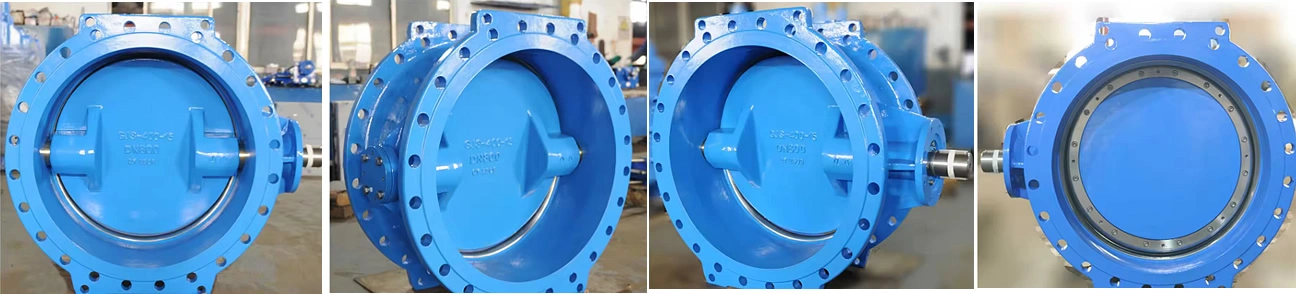

A. Double Eccentric Design: Reduced Wear & Low Torque

The double eccentric design is the core advantage of this valve, setting it apart from traditional concentric butterfly valves. The first eccentricity refers to the offset of the valve stem axis relative to the center of the valve seat; the second eccentricity is the offset of the valve stem axis relative to the center of the disc. This dual-offset structure ensures that the disc only contacts the seat at the final stage of closing, minimizing friction between the disc and seat during opening and closing.

This design not only reduces operational torque by 30–40% but also significantly reduces seat wear, extending the seat’s service life by 50% compared to concentric designs. In applications with frequent on-off operations (e.g., water treatment plants), this feature minimizes maintenance frequency and operational costs. Additionally, the double eccentric design enables bidirectional sealing, eliminating the need for check valves and simplifying pipeline design.

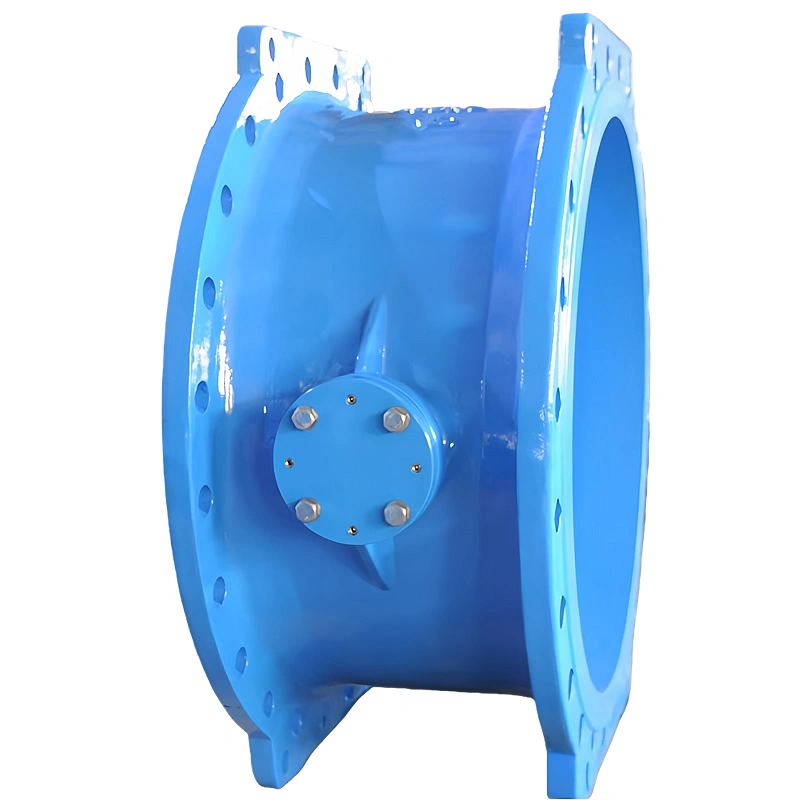

B. Ductile Cast Iron Construction with Epoxy Coating: Durability & Corrosion Resistance

The valve body and bonnet are made of A536 65-45-12 ductile cast iron, which offers superior mechanical properties to gray cast iron. Ductile cast iron’s spherical graphite structure enhances its tensile strength, impact resistance, and ductility, making it resistant to cracking under pressure surges and thermal cycling — critical for harsh industrial environments.

To further enhance corrosion resistance, the inner and outer surfaces of the valve body are coated with high-quality epoxy resin. The coating thickness is strictly controlled at ≥250μm, forming a seamless barrier against moisture, chemicals, and abrasive media. This coating ensures the valve maintains structural integrity in humid, corrosive environments such as sewage treatment plants and coastal areas, with a service life of 8–12 years.

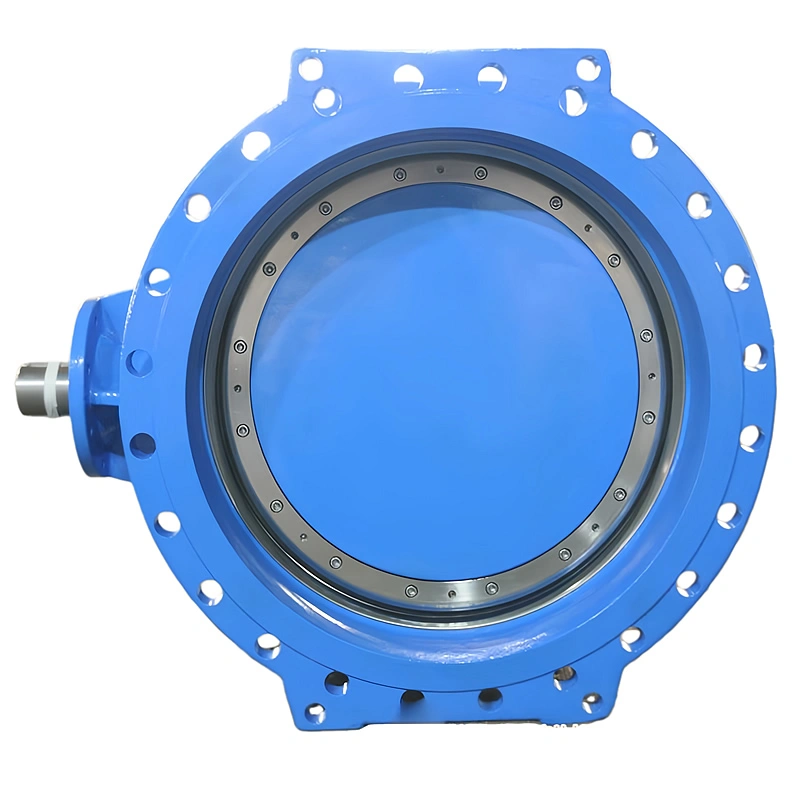

C. Replaceable Seat Design: Maintenance Flexibility

The valve adopts a replaceable seat design, allowing on-site seat replacement without removing the valve from the pipeline. This significantly reduces downtime during maintenance — a key advantage for continuous-process facilities such as petrochemical plants and power stations. The seat is easily accessible by removing the bonnet or end flange, and no special tools are required for replacement.

TIANYU offers a range of seat materials to match specific media and operating conditions, enabling users to adapt the valve to changing process requirements without replacing the entire valve. This flexibility not only reduces maintenance costs but also extends the valve’s overall lifecycle.

D. Versatile Actuation Options: Adaptable to Diverse Systems

The valve is available in three actuation types, catering to the unique needs of different applications:

- Manual actuation: Cost-effective for small-to-medium diameter valves (DN50-DN300) or systems with infrequent operation. The anti-slip handwheel provides clear visual confirmation of the valve’s position (parallel to the pipeline = open; perpendicular = closed).

- Pneumatic actuation: Ideal for automated systems requiring fast, reliable operation (e.g., batch processing lines in chemical plants). Spring-return actuators ensure fail-safe operation, preventing system overpressure or media leakage in the event of air supply failure.

- Electric actuation: Suitable for remote control and precision regulation (e.g., SCADA-integrated water supply networks). The electric actuator features adjustable torque limits and position feedback, enabling real-time monitoring and control of the valve’s status.

E. Bubble-Tight Sealing: Reliable Performance

Equipped with high-quality soft seals (EPDM/PTFE/VITON) or metal seals, the valve achieves ANSI/FCI Class VI sealing performance (for soft seals), ensuring bubble-tight closure. The combination of the double eccentric design and preloaded seat ensures uniform sealing pressure across the entire seat surface, even under fluctuating pressure and temperature conditions.

For applications requiring strict leakage control (e.g., handling toxic or flammable media), the valve can be equipped with a secondary sealing system, further enhancing sealing reliability. This feature makes the valve suitable for critical service in petrochemical, pharmaceutical, and food processing industries.

IV. Manufacturing Process & Quality Control

A. Raw Material Procurement & Inspection

TIANYU adheres to strict raw material sourcing and inspection protocols to ensure product quality and traceability:

- Material Sourcing: Ductile cast iron blanks, stainless steel components, and seal materials are sourced exclusively from ISO 9001-certified suppliers. Each batch of raw materials is accompanied by a Material Test Certificate (MTC) detailing chemical composition, mechanical properties, and heat treatment history.

- Material Verification: Incoming ductile cast iron blanks undergo spectral analysis (XRF) to confirm compliance with A536 65-45-12 standards. Tensile, yield, and impact tests are performed on sample specimens to ensure mechanical properties meet requirements (tensile strength ≥415MPa, impact toughness ≥12J at -20℃).

- Non-Destructive Testing (NDT): Cast components (body, bonnet) undergo ultrasonic testing (UT) to detect internal defects such as porosity and cracks, and magnetic particle testing (MPI) to inspect surface flaws. Only defect-free materials proceed to the next manufacturing stage.

B. Casting & Heat Treatment

Casting and heat treatment are critical to ensuring the structural integrity of the valve:

- Precision Casting: Ductile cast iron billets are melted in an electric arc furnace and poured into sand molds using the lost foam casting process. This process ensures dimensional accuracy and surface smoothness, reducing the need for subsequent machining. The casting process is strictly controlled to minimize internal defects such as shrinkage and porosity.

- Heat Treatment: Cast components undergo normalization (850–900℃, air-cooled) to relieve casting stress and refine the grain structure. This treatment enhances the material’s toughness and ductility, ensuring the valve can withstand pressure surges and thermal cycling. Post-heat treatment hardness is controlled between 170–230 HB.

- Descaling & Cleaning: Cast parts are shot-blasted to remove surface oxide scale and sand, then cleaned with ultrasonic baths to eliminate residual contaminants. This ensures clean surfaces for subsequent coating and assembly.

C. Precision Machining

Machining is performed using high-precision CNC equipment to meet tight tolerances:

- Body & Bonnet Machining: CNC lathes and milling machines process flange faces, seat pockets, and stem bores. Flange faces are machined to a flatness tolerance of ≤0.02mm/m and surface roughness Ra 1.6μm to ensure tight sealing. Seat pockets are honed to a coaxiality tolerance of ≤0.01mm relative to the valve bore, ensuring uniform contact between the disc and seat.

- Disc Machining: The disc is precision turned and milled to match the double eccentric design. The sealing surface is lapped to Ra ≤0.4μm to enhance sealing performance. For full-port designs, the disc bore is machined to match the nominal pipe size, minimizing flow resistance.

- Stem Machining: The stem is turned and ground to a diameter tolerance of ±0.01mm and polished to Ra ≤0.8μm. The anti-blowout shoulder is precision-machined to engage securely with the valve body, preventing stem ejection under high pressure.

D. Coating Process

The epoxy coating process is critical to the valve’s corrosion resistance:

- Surface Preparation: Machined components are degreased and sandblasted to achieve a surface roughness of Ra 40–80μm, ensuring strong adhesion between the coating and the substrate.

- Coating Application: High-quality epoxy resin is applied using electrostatic spraying, ensuring uniform coating thickness. The coating thickness is measured at multiple points to ensure it meets the minimum requirement of 250μm.

- Curing: Coated components are cured in an oven at 180℃ for 2 hours, forming a hard, wear-resistant coating. Post-curing inspection ensures no pinholes, cracks, or delamination.

E. Assembly & Comprehensive Testing

Assembly and testing adhere to EN 12266 and API 598 standards to ensure reliable performance:

- Component Cleaning: All parts (body, disc, seat, stem, packing) are degreased and ultrasonic-cleaned to remove oil, debris, and metal particles, preventing contamination of sealing surfaces.

- Assembly Sequence: The seat is first installed in the valve body, followed by the disc, stem, packing, and bonnet. Fasteners are tightened in a crisscross pattern to uniform torque (per ASME B18.2.1) to ensure even clamping force. Actuators (pneumatic/electric) are mounted in accordance with ISO 5211 standards, and the connection is tested for torque transmission.

- Pressure Testing:

- Hydrostatic Shell Test: 1.5× rated pressure is applied to the valve body cavity for 30 minutes. No leakage, deformation, or pressure drop is permitted.

- Hydrostatic Seat Test: 1.1× rated pressure is applied to each seat (bidirectional) for 15 minutes. Leakage is measured using a bubble counter, complying with ANSI/FCI Class IV/VI.

- Pneumatic Test (Optional): 0.6MPa air pressure is applied to the body and seats for 10 minutes. No audible leakage is permitted.

- Operational Testing: The valve is cycled 50 times (open-close) to verify smooth operation, consistent torque, and correct actuator performance (for pneumatic/electric models).

- Specialized Testing:

- Fugitive Emissions Test: ISO 15848-1 Class BH compliance is verified using methane and a flame ionization detector (FID).

- Low-Temperature Test: For valves used in cold environments, testing at -40℃ ensures sealing performance and operational reliability.

F. Final Inspection & Packaging

Before shipment, each valve undergoes a final inspection and careful packaging:

- Visual Inspection: Each valve is inspected for surface defects (scratches, dents), proper machining, and correct marking (DN, PN, TIANYU logo, certifications). Valves with surface scratches deeper than 0.05mm are rejected.

- Documentation: Each valve is shipped with a comprehensive Documentation Package, including MTC, Hydrostatic Test Certificate, EN 10204 3.1/3.2 Certificate, and CE PED Declaration of Conformity.

- Packaging: Valves are packaged in plywood crates with foam insulation to prevent damage during transportation. Flange ends are capped with plastic protectors, and actuators are wrapped in waterproof film. Crates are labeled with handling instructions, product information, and warning signs for safe delivery.