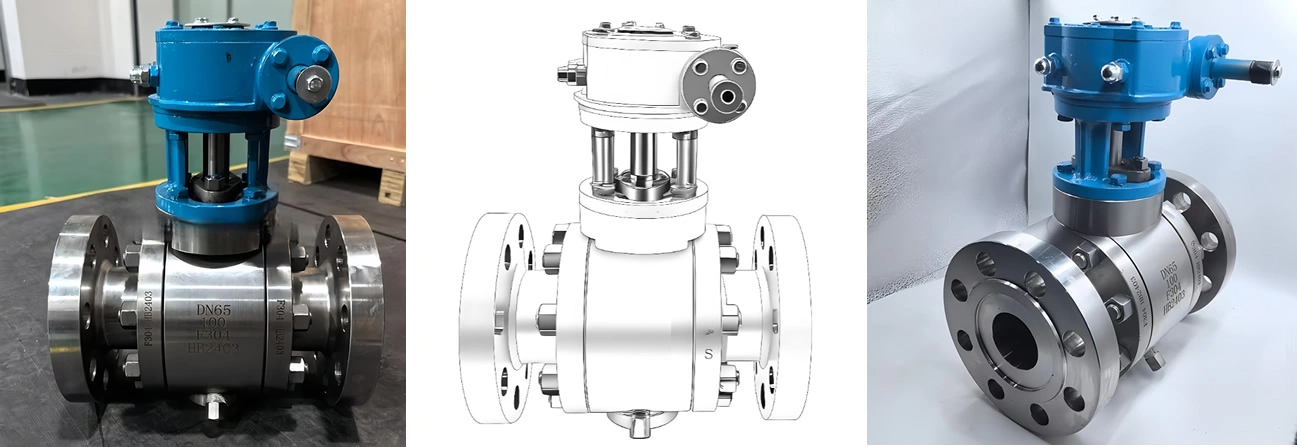

TIANYU API 608 GB/T 12237 ASME B16.34 CE Certified DN50-DN900 PN10-PN100 SS304/316 Forged 3PC Flange Trunnion Mounted Ball Valve – Manual/Pneumatic/Electric Operation for Petrochemical Water Treatment Power Industry

I. Product Overview

In the realm of industrial fluid control, trunnion mounted (fixed) ball valves stand as a cornerstone for high-pressure, high-temperature, and critical service applications—offering unmatched stability, sealing reliability, and long-term durability. TIANYU’s Forged 3PC Flange Trunnion Mounted Ball Valve, engineered to align with global standards including API 608 (Steel Ball Valves), GB/T 12237 (Ball Valves for Industrial Use), and ASME B16.34 (Valves for Pressure Piping), merges precision forging technology, premium stainless steel materials, and advanced sealing systems to meet the rigorous demands of petrochemical, power generation, water treatment, and general industrial sectors.

Crafted from forged SS304/316 stainless steel (with options for duplex steel, chrome-molybdenum steel, and low-temperature steel), this valve features a three-piece (3PC) body design, trunnion-supported ball, and versatile sealing solutions (EPDM, PTFE, graphite) to accommodate media ranging from water and steam to oil and mild corrosives. The trunnion-mounted configuration—where the ball is secured by upper and lower shafts (trunnions)—eliminates lateral movement under high pressure, reducing seat wear and operational torque, while the three-piece structure enables easy maintenance without removing the valve from the pipeline.

Rated for nominal diameters from DN50 to DN900 (2” to 36”) and pressure classes from PN10 (1.0MPa) to PN100 (10.0MPa), the valve operates reliably across an extreme temperature range of -196℃ to 600℃—covering cryogenic LNG service, ambient fluid transfer, and high-temperature steam applications. Available in manual, pneumatic, or electric actuation, it delivers flexible control options for diverse system requirements, from small-scale water treatment plants to large petrochemical refineries. As a trusted solution for critical flow control, this valve balances structural integrity, sealing performance, and operational efficiency to minimize downtime and lifecycle costs.

II. Important Attribute Specifications

A. Material Composition

Every component is selected to withstand harsh industrial conditions, with material versatility to match specific media, pressure, and temperature requirements:

- Valve Body, Bonnet & Flange: Forged SS304 (ASTM A182 F304) as standard—an austenitic stainless steel with chemical composition (Cr: 18–20%, Ni: 8–12%, C ≤0.08%) delivering tensile strength ≥515MPa, yield strength ≥205MPa, and excellent corrosion resistance to water, steam, and mild chemicals. Optional SS316 (ASTM A182 F316) for enhanced chloride resistance (ideal for coastal or chemical applications), duplex stainless steel (2205) for high strength and corrosion resistance, chrome-molybdenum steel (F22) for high-temperature service, and low-temperature steel (A350 LF2) for cryogenic applications down to -196℃. All forgings undergo ultrasonic testing (UT) to eliminate internal defects.

- Ball: Forged SS304/316 with special surface treatment (HF hardening) for wear resistance—Rockwell hardness ≥58 HRC. The ball features a full-port design to minimize pressure drop, with a precision-lapped sealing surface (Ra ≤0.4μm) ensuring uniform contact with the valve seat. For high-temperature or abrasive media, the ball is optionally coated with Stellite (cobalt-chromium alloy) to extend service life.

- Trunnions & Stem: SS304/316 stainless steel (ASTM A276) for trunnions and stem—providing corrosion resistance and structural stability. The stem features an anti-blowout design, with a enlarged shoulder that engages the bonnet to prevent ejection under excessive pressure. The trunnions are fitted with self-lubricating PTFE-impregnated bronze bearings, reducing operational torque and ensuring smooth rotation.

- Seat: Dual-material design with metal base (SS304/316) and replaceable inserts. EPDM (Ethylene Propylene Diene Monomer) inserts for general service (temperature range -40℃ to 120℃), compatible with water, steam, and mild alkalis. PTFE (Polytetrafluoroethylene) inserts for chemical compatibility (temperature -20℃ to 150℃), resistant to acids, solvents, and hydrocarbons. Graphite inserts for high-temperature service (up to 600℃), suitable for steam and hot oil applications. All seat inserts are preloaded with stainless steel springs for self-compensating sealing, accommodating minor wear or thermal expansion.

- Packing & Gaskets: Multi-layer flexible graphite packing with PTFE inner ring (complying with ISO 15848-1 Class AH for low fugitive emissions) for stem sealing. Bonnet gaskets are spiral-wound graphite with SS304/316 metal reinforcement (ASME B16.20), ensuring tight sealing under thermal cycling and pressure fluctuations. Flange gaskets are non-asbestos fiber-reinforced rubber or spiral-wound graphite, compatible with ASME B16.5/GB/T 9113 flanges.

- Fasteners: SS304/316 stainless steel bolts (ASTM A193 B8/B8M) and nuts (ASTM A194 8/8M) for corrosive environments; carbon steel bolts (ASTM A193 B7) and nuts (ASTM A194 2H) for general service—providing uniform clamping force across the flange and bonnet connections.

B. Dimensional & Pressure-Temperature Parameters

- Port Size (DN/NPS): DN50 (2”) to DN900 (36”), full-port design (bore diameter equal to nominal pipe size) to optimize flow efficiency. Flow coefficient (Cv) ranges from 120 (DN50) to 18,000 (DN900), minimizing pressure drop and energy consumption in high-flow applications (e.g., water transmission pipelines, petrochemical process lines).

- Pressure Rating: PN10 (1.0MPa), PN16 (1.6MPa), PN25 (2.5MPa), PN40 (4.0MPa), PN64 (6.4MPa), PN100 (10.0MPa)—aligned with ASME B16.34 and GB/T 12224 pressure-temperature ratings. At 20℃, PN100 models withstand 10.0MPa, making them suitable for high-pressure oil & gas and power generation applications.

- Temperature Range: -196℃ to 600℃, depending on seat material. Cryogenic service (-196℃) with low-temperature steel (A350 LF2) and PTFE seats; ambient to high-temperature service (up to 600℃) with graphite seats and F22 chrome-molybdenum steel body.

- End Connections: Flange (ASME B16.5, GB/T 9113, JB/T 79)—Raised Face (RF) as standard, Ring Type Joint (RTJ) optional for high-pressure PN64-PN100 service. Flange dimensions comply with global standards, ensuring compatibility with existing pipeline systems.

- Face-to-Face Dimensions: Compliant with API 608 and GB/T 12221, ranging from 178mm (DN50) to 1524mm (DN900)—ensuring interchangeability with valves from other manufacturers for easy retrofitting.

C. Operational Performance Parameters

- Sealing Performance: ANSI/FCI 70-2 Class IV (EPDM/PTFE seats) to Class V (graphite seats) sealing. For liquid media, leakage rate ≤0.01% of nominal flow; for gas media, leakage rate ≤0.1Nm³/h (DN50) under rated pressure—preventing media loss and environmental contamination.

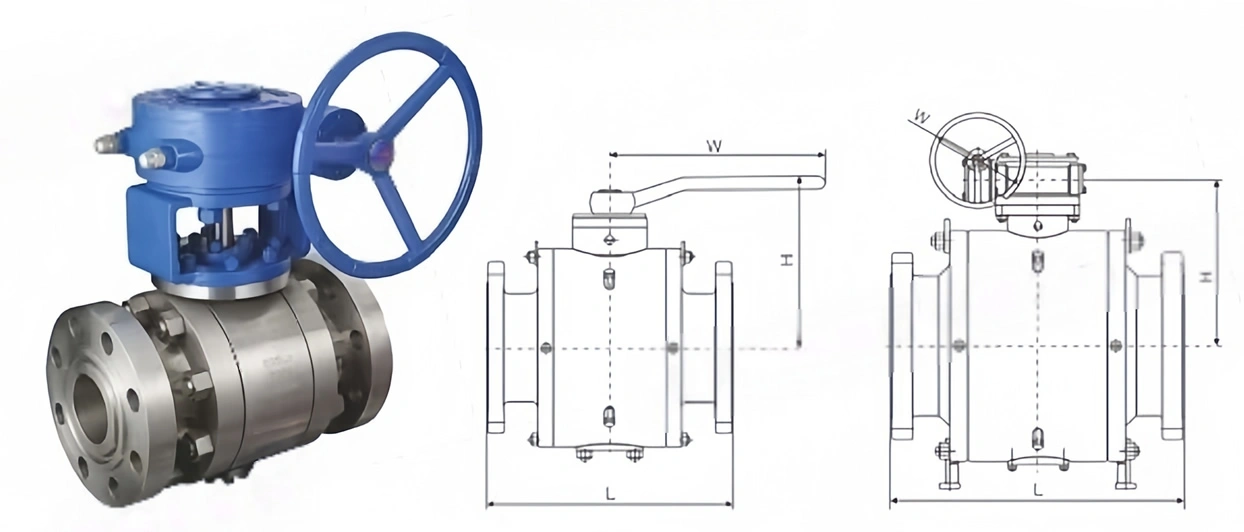

- Actuation Options:

- Manual: Cast iron handwheel with anti-slip grip, worm gear operator for large-diameter valves (DN300+) to reduce operational torque (gear ratio 30:1 to 100:1).

- Pneumatic: Double-acting or spring-return pneumatic actuators (ISO 5211 mounting), explosion-proof (Ex d IIC T4) for hazardous environments, air supply pressure 0.4–0.6MPa, stroke time 5–30 seconds.

- Electric: AC/DC electric actuators (IEC 60534), with remote control, position feedback, and torque limiting functions, suitable for integration into SCADA systems, stroke time 10–60 seconds.

- Operating Torque: 50N·m (DN50, PN10) to 2500N·m (DN900, PN100) for manual operation; reduced by 40–60% with worm gear or actuator operation.

- Cycle Life: ≥100,000 open/close cycles under normal operating conditions, with maintenance interval of 24–36 months—extending service life and reducing downtime.

D. Certifications & Compliance

- Design & Manufacturing Standards: API 608, GB/T 12237, ASME B16.34, ISO 14313 (Pipeline Ball Valves), CE PED 2014/68/EU (Pressure Equipment Directive).

- Quality & Environmental Certifications: ISO 9001 (Quality Management System), ISO 14001 (Environmental Management), ISO 45001 (Occupational Health and Safety).

- Material Certifications: EN10204 3.1/3.2 Material Test Certificates (MTC), FDA 21 CFR 177.2600 (for food-grade applications), NACE MR0175 (for sour service).