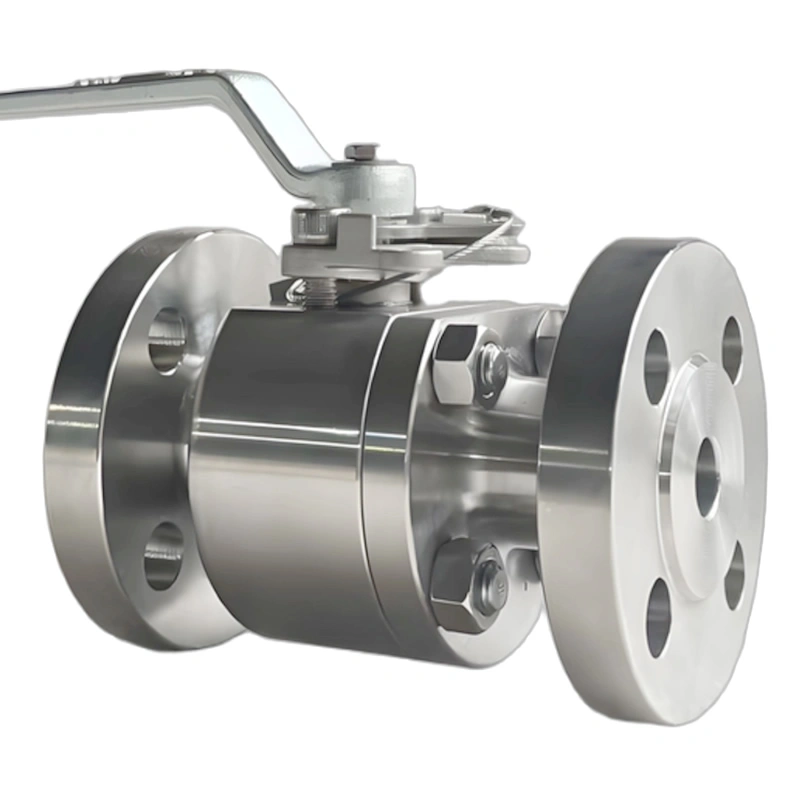

In the landscape of small-bore industrial fluid control, floating ball valves emerge as a compact, cost-effective solution for on-off flow regulation—and TIANYU’s DN15 PN16 SS304 Floating Ball Valve elevates this utility with rigorous compliance to global standards, hygienic material pairing, and reliable performance. Engineered to align with API 608 (Steel Ball Valves for Petroleum, Petrochemical and Allied Industries), ASME B16.34 (Valves, Flanges, Fittings and Gaskets for Pressure Piping), and CE PED 2014/68/EU requirements, this valve merges the corrosion resistance of SS304 stainless steel, the chemical inertness of PTFE soft sealing, and the simplicity of manual lever operation to serve low-to-medium pressure systems across hygiene-critical and light industrial sectors.

At its core, the floating ball design (where the ball is unsupported by trunnions, relying on media pressure to seal against the seat) is optimized for small diameters like DN15: it eliminates bulky support components, reducing the valve’s footprint and manufacturing cost while maintaining tight sealing integrity. The all-SS304 wetted components (body, ball, stem) resist rust and mild corrosion, making it suitable for potable water, food-grade media, and light chemical applications, while the PTFE valve seat delivers bubble-tight closure (ANSI/FCI Class VI) to prevent product contamination or fluid loss.

The manual lever handle enables 90-degree on-off control in seconds, requiring no external power—ideal for small-scale equipment, laboratory setups, or remote pipeline branches where automation is unnecessary. Its flange connection (ASME B16.5 Class 150) ensures compatibility with standard industrial piping, while the compact face-to-face dimension (aligned with API 608) simplifies retrofitting into existing systems. As a workhorse for small-bore flow control, this valve balances hygiene, durability, and operational simplicity to meet the demands of diverse low-volume applications.

Every component is selected to prioritize corrosion resistance, sealing integrity, and compatibility with hygiene-critical or mild industrial media:

- Valve Body & Ball: SS304 Stainless Steel (ASTM A182 Grade F304), a austenitic stainless steel widely recognized for its balanced mechanical and corrosion-resistant properties. Its chemical composition is strictly controlled: Chromium (18–20%), Nickel (8–12%), Carbon (≤0.08%), Manganese (≤2.00%), Phosphorus (≤0.045%), Sulfur (≤0.030%). This formulation delivers a tensile strength of ≥515MPa, yield strength of ≥205MPa, and elongation of ≥40%—sufficient to withstand PN16 pressure loads and cyclic thermal expansion. The body and ball are produced via cold forging (for DN15, a process that ensures dense, defect-free material) to eliminate porosity common in casting, then precision-machined to ensure dimensional accuracy.

- Valve Seat: PTFE (Polytetrafluoroethylene, ASTM D4894), a fluoropolymer prized for its chemical inertness and low friction. The seat is manufactured from FDA 21 CFR 177.1550-compliant resin, ensuring it is non-toxic and safe for direct contact with food, beverages, and potable water. PTFE exhibits resistance to nearly all non-oxidizing acids, alkalis, solvents, and hydrocarbons, with a continuous operating temperature range of -20℃ to 150℃. The seat is molded into a rigid ring (matching the valve body’s seat groove) to ensure secure installation and uniform contact with the ball.

- Valve Stem: SS304 Stainless Steel (ASTM A276 Grade 304), designed with an anti-blowout shoulder that engages the valve body’s bonnet bore. This feature prevents the stem from being ejected under excessive media pressure—a critical safety requirement for pressure-containing equipment. The stem is precision-turned to a diameter tolerance of ±0.01mm, then polished to a surface roughness of Ra ≤0.4μm to minimize friction with the packing assembly, ensuring smooth rotation during lever operation.

- Packing & Seals: PTFE-impregnated graphite packing, a multi-layer assembly that provides leak-tight sealing around the stem while maintaining compatibility with hygiene-critical media. The packing is compressed to 10–15% of its original thickness during assembly to balance sealing performance and operational torque. Flange gaskets comply with ASME B16.20, utilizing non-asbestos fiber-reinforced PTFE for environmental compatibility and reliable sealing between the valve and pipeline flanges.

- Fasteners & Handle: Flange fasteners (bolts and nuts) are manufactured from SS304 Stainless Steel (ASTM A193 Grade B8 and ASTM A194 Grade 8), ensuring corrosion resistance in washdown or humid environments. The manual lever handle is cast from aluminum alloy (ASTM B108) with a black anodized finish and an orange anti-slip grip, designed to withstand repeated use and provide secure handling even with gloved hands.

- Port Size (DN/NPS): DN15 (1/2”), configured as a full-port (bore diameter equal to the nominal pipe size). This design minimizes pressure drop across the valve, with a flow coefficient (Cv) of approximately 15—sufficient to handle low-to-medium flow rates (e.g., 15m³/h of water) without restricting system performance. The full-port bore also facilitates easy cleaning, a critical feature for hygiene-critical applications like food processing.

- Pressure Rating: PN16 (1.6MPa), aligned with ASME B16.34 pressure-temperature ratings for stainless steel valves. At 20℃ (ambient temperature), the valve is rated for a maximum working pressure of 1.6MPa; at the upper temperature limit of the PTFE seat (150℃), the rated pressure is reduced to 1.0MPa (per ASME B16.34 guidelines for elastomer-sealed valves).

- Temperature Range: -20℃ to 150℃ (continuous operation with PTFE seat). For applications requiring lower temperatures (down to -40℃), an optional FKM (Viton) seat is available; for higher temperatures (up to 200℃), PFA (perfluoroalkoxy alkane) seats can be specified (both maintaining FDA compliance where required).

- End Connection: Flange (ASME B16.5 Class 150), with a Raised Face (RF) sealing surface. The flange dimensions for DN15 Class 150 are standardized: outer diameter of 95mm, bolt circle diameter of 60.3mm, 4×M10 bolt holes, and a flange thickness of 12.7mm. This ensures compatibility with standard industrial pipeline flanges, eliminating the need for custom adapters.

- Face-to-Face Dimensions: Compliant with API 608, measuring 90mm for DN15 Class 150. This short face-to-face length is 30–40% more compact than comparable globe valves, making the valve suitable for installation in tight spaces (e.g., inside equipment skids or laboratory fume hoods).

- Sealing Performance: ANSI/FCI 70-2 Class VI (bubble-tight sealing), the highest standard for soft-seal valves. For liquid media, the leakage rate is limited to ≤0.1×DN mm³/min—translating to ≤1.5mm³/min for DN15. This level of sealing ensures no product loss, no contamination of process media, and compliance with hygiene standards (e.g., HACCP for food processing).

- Operating Torque: Approximately 15N·m for DN15 PN16, a torque level that can be easily managed with a single hand (even with protective gloves). The low torque is enabled by the PTFE seat’s self-lubricating properties, which reduce friction between the ball and seat during rotation.

- Cycle Life: ≥50,000 open/close cycles under normal operating conditions (clean media, proper maintenance). The PTFE seat’s elasticity compensates for minor wear on the ball’s sealing surface, extending the valve’s service life beyond rigid metal-seal alternatives.

- Switch Time: ≤3 seconds for a full 90-degree rotation (open to closed), enabling rapid response to process changes or emergency shutdowns. The lever’s design provides clear visual confirmation of valve position: parallel to the pipeline = open; perpendicular = closed.