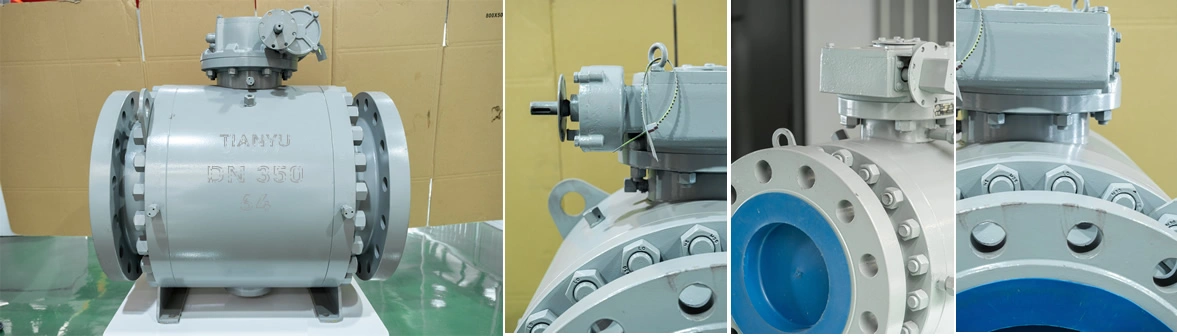

TIANYU trunnion mounted flanged carbon steel ball valve is a rugged, high-performance flow control solution engineered specifically for the demanding requirements of oil & gas pipelines, natural gas transmission systems, and heavy industrial production. As a trunnion-mounted (fixed ball) valve, it features a structurally superior design where the ball is supported by upper and lower trunnions—transferring fluid pressure forces to robust bearings instead of relying on valve seats. This configuration ensures exceptional sealing stability, reduced operational torque, and extended service life in high-pressure, high-cycle applications where leakage or structural failure could lead to catastrophic safety hazards, environmental damage, or costly production downtime.

Constructed from premium carbon steel (A105 forged carbon steel or WCB cast carbon steel), this valve adheres to globally recognized industry standards including API 6D (pipeline valves), API 608 (trunnion-mounted ball valves), ASME B16.34 (valve dimensions and pressure-temperature ratings), and ASME B16.5 (flange specifications). It is optimized for DN350 (14”) pipelines, with a pressure rating spanning Class 150 to Class 600 (PN25 to PN100)—catering to low-to-ultra-high pressure needs of oil & gas, natural gas, and industrial fluid systems.

The valve features a flanged connection for secure, leak-tight installation and a hard-seal (metal-to-metal) configuration to withstand harsh media, high temperatures, and abrasive particles common in oil & gas applications. Drive options include manual (lever/worm gear), pneumatic, electric, hydraulic, and electro-hydraulic actuation—catering to manual, semi-automated, and fully integrated process control systems. Whether deployed in cross-country oil pipelines, natural gas distribution networks, refinery process lines, or industrial production facilities, this valve delivers uncompromising reliability, safety, and efficiency—making it a trusted choice for industries where operational integrity and compliance are non-negotiable.

- Port Size: DN350 (14”) as the flagship size, with a full-port configuration as standard. The full-port design ensures the valve’s internal bore matches the pipeline diameter (350mm), minimizing pressure drop (Cv value up to 1200 for DN350) and enabling pipeline pigging/cleaning—critical for oil & gas transmission lines. The valve is also available in a size range of DN100 to DN600 (4” to 24”) to accommodate diverse pipeline requirements.

- Pressure Rating: Class 150 to Class 600 (PN25 to PN100), aligning with ASME B16.34 pressure-temperature ratings for carbon steel. Hydrostatic testing follows API 598: 1.5× rated pressure for the valve shell (body/bonnet) and 1.1× rated pressure for seats—ensuring no leakage, sweating, or structural deformation under operating conditions.

- Class 150/PN25: Suitable for low-to-medium pressure natural gas distribution and industrial fluid systems.

- Class 300/PN40: Ideal for refinery process lines, oil gathering pipelines, and natural gas transmission.

- Class 600/PN100: Engineered for ultra-high-pressure applications such as offshore oil wellheads, high-pressure gas pipelines, and industrial reactor feed lines.

- Temperature Range: -29℃ to 425℃, optimized for carbon steel’s thermal stability and hard-seal compatibility. This range covers ambient natural gas, heated crude oil, and high-temperature industrial media (e.g., process steam), outperforming soft-sealed valves that degrade above 200℃.

Each component is selected for high-pressure resilience, wear resistance, and compatibility with oil, gas, and industrial fluids:

- Valve Body & Bonnet:

- A105 Forged Carbon Steel (ASTM A105): For Class 300-600 high-pressure applications, offering superior tensile strength (485–655MPa), yield strength (≥240MPa), and impact resistance. Undergoes normalizing heat treatment (900–950℃, air-cooled) to relieve internal stresses from forging.

- WCB Cast Carbon Steel (ASTM A216): For Class 150-300 medium-pressure applications, providing cost-effectiveness and reliable performance in non-corrosive media.

- Ball & Trunnions: Solid carbon steel (A105/WCB) ball with precision-ground surface finish (Ra ≤0.2μm) for uniform sealing contact. Trunnions (upper/lower) are integral to the ball, made from the same carbon steel material and surface-hardened (HRC 30–35) to reduce wear. For abrasive media (e.g., natural gas with sand particles), the ball’s sealing surface is hard-faced with Stellite 6 (cobalt-chromium alloy, HRC ≥58) to extend service life by 3–5 times.

- Seal Materials:

- Hard Seal: Metal-to-metal sealing with Stellite 6 overlay on valve seats, delivering ANSI/FCI Class IV leakage performance—ideal for high-temperature, high-pressure, and abrasive media (e.g., crude oil, natural gas).

- Optional Soft Seal: PTFE/RPTFE for low-temperature, non-abrasive media (e.g., purified natural gas), providing ANSI/FCI Class VI bubble-tight sealing (near-zero leakage).

- Valve Stem: A105 carbon steel or 17-4PH precipitation-hardened stainless steel, featuring an anti-blowout design to prevent ejection under pressure. Sealed with graphite-impregnated PTFE packing to minimize fugitive emissions (compliant with ISO 15848-1 Class BH).

- Flanges & Fasteners: Integral flanges machined to ASME B16.5 standards with Raised Face (RF) or Ring Type Joint (RTJ) finishes. Fasteners are ASTM A193 B7 alloy steel bolts and ASTM A194 2H nuts—offering high tensile strength (≥827MPa) and resistance to vibration-induced loosening.

- Gaskets: Spiral-wound gaskets (carbon steel with graphite filler) complying with ASME B16.20, ensuring leak-tight flange sealing under pressure and temperature fluctuations.

- Connection Type: Flanged (ANSI B16.5/ASME B16.47) as standard:

- RF Flange: Suitable for Class 150-300 applications, providing a secure seal with spiral-wound gaskets—ideal for general industrial and natural gas distribution use.

- RTJ Flange: Optional for Class 400-600 ultra-high-pressure systems (e.g., offshore oil platforms), using metal ring gaskets to withstand extreme pressure and prevent fugitive emissions.

- Drive Options:

- Manual: Worm gear operation as standard for DN350, reducing torque requirements by 5–10 times and enabling single-person operation. A lever option is available for smaller sizes (DN100-DN200).

- Pneumatic: Double-acting (compressed air for both opening and closing) or spring-return (auto-close/open on air supply loss) actuators. Cycle times for DN350 range from 20–40 seconds, making spring-return models ideal for emergency shutdowns in oil & gas pipelines.

- Electric: Quarter-turn electric actuators with 4–20mA control signals, integrating with SCADA/DCS systems for remote monitoring and automation. IP67-rated enclosures ensure protection against dust and water, suitable for outdoor pipeline installations.

- Hydraulic/Electro-Hydraulic: For ultra-high-torque applications (DN400+ or Class 600), providing precise control in heavy-industry settings (e.g., large-scale refineries).

- Functional Features:

- Trunnion Mounted Design: Trunnion support distributes fluid pressure forces to bearings, eliminating seat deformation and reducing operational torque—critical for high-pressure Class 600 applications.

- Bidirectional Sealing: Dual seats (upstream/downstream) enable reliable shut-off in both flow directions, simplifying pipeline design and eliminating installation direction constraints.

- Anti-Static Device: A conductive spring connecting the ball, stem, and body dissipates static charges (resistance ≤10Ω)—essential for natural gas and oil applications to prevent spark-induced explosions.

- Fire-Safe Design: Compliant with API 607, ensuring metal-to-metal sealing if non-metallic components (e.g., packing) degrade in a fire—preventing catastrophic media release.

- Design & Manufacturing Standards: API 6D (pipeline valves), API 608 (trunnion-mounted ball valves), ASME B16.34 (valve pressure-temperature ratings), ASME B16.5 (flange dimensions), API 598 (valve testing and inspection).

- Quality & Safety Certifications: ISO 9001 (quality management), CE (EU safety compliance), ATEX (optional for explosive gas atmospheres), IECEx (global hazardous area compliance).

- Performance Certifications: NACE MR0175 (optional for sour gas service with H₂S), ISO 15848-1 (fugitive emissions), ANSI/FCI Class IV (leakage).