The double eccentric design’s friction-free stroke reduces seal wear by 70% compared to concentric butterfly valves. In a municipal water distribution project with DN600 valves, TIANYU’s double eccentric model operated for 10 years without seal replacement, while concentric valves required maintenance every 3 years—reducing lifecycle costs by 40%.

PTFE soft seal and metal hard seal options eliminate the need for multiple valve types across projects. For example, a water treatment plant can use PTFE-sealed valves in potable water lines (ANSI Class VI leakage) and metal-sealed valves in high-temperature steam condensate lines (≤350℃), streamlining inventory and maintenance.

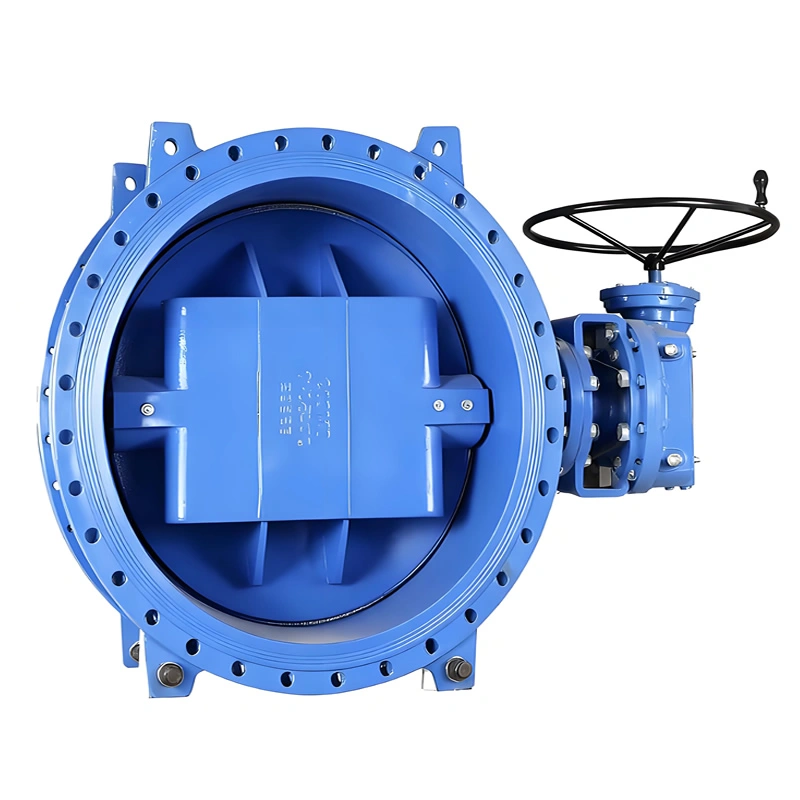

Manual operation eliminates actuator costs, wiring, and power consumption—saving 30–50% upfront compared to automated valves. For remote rural irrigation systems or small wastewater plants, this reduces project budgets while maintaining reliable performance. The gear-reduction handwheel also minimizes labor requirements, with DN3000 valves operable by a single worker.

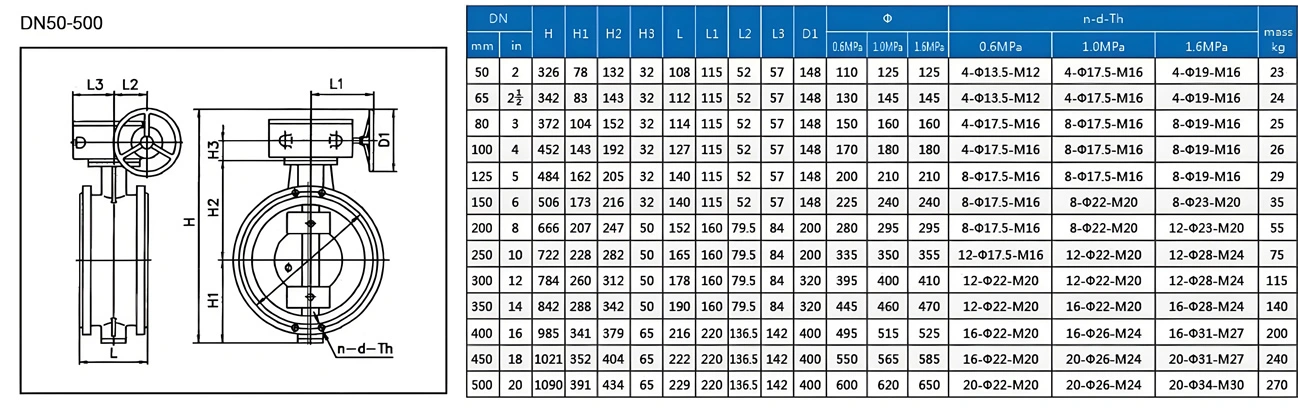

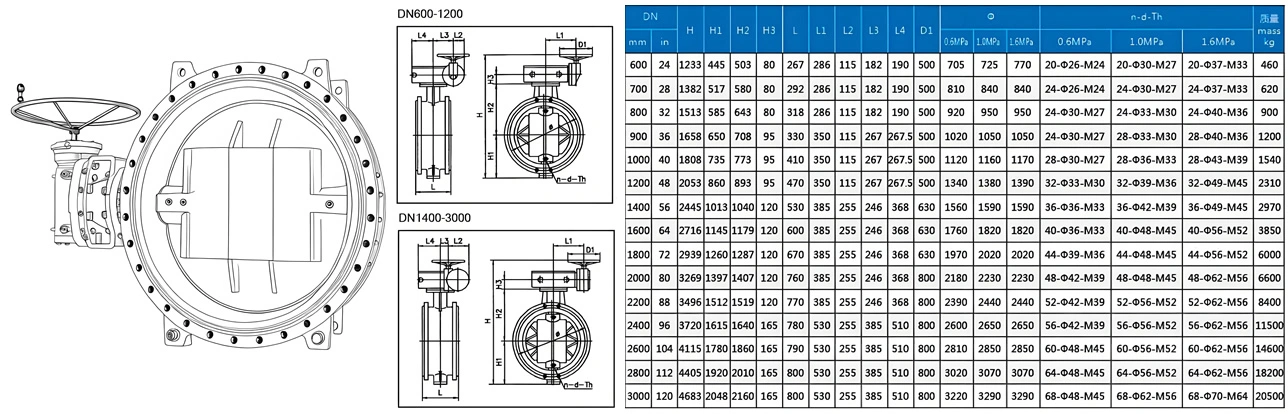

DN50–DN3000 diameter range and PN0.6–PN6.4 pressure range adapt to diverse scenarios: from residential water lines (DN50 PN1.0) to large municipal water mains (DN3000 PN1.6) and industrial high-pressure cooling systems (DN800 PN6.4). This scalability makes TIANYU’s valve a one-stop solution for contractors and plant operators.

Stainless steel, cast steel, and ductile iron materials resist rust, scaling, and chemical corrosion in water media. In coastal municipal water systems, 316 stainless steel valves operated for 8 years without corrosion, outperforming carbon steel valves that required replacement every 2–3 years. The Stellite 6 metal seal also withstands abrasive particles in river water, avoiding seal failure caused by wear.

API 609, ASME B16.5, and ISO 9001 certifications ensure compatibility with global pipeline components. A European municipal project, for example, integrated TIANYU’s DN1200 valves (CE-certified, EN 1092-1 flanges) into an existing network without modifications, avoiding delays from non-compliant components.