The butterfly valve stands as a cornerstone of modern fluid control systems, revolutionizing industrial processes across diverse sectors with its unique blend of efficiency, versatility, and cost-effectiveness. From regulating the flow of raw materials in manufacturing plants to ensuring safety in high-stakes energy production, this valve type has become indispensable in applications where precision, durability, and adaptability are paramount. This comprehensive guide delves into the core characteristics, operational mechanisms, design variations, and practical applications of butterfly valves, offering a technical yet accessible overview for engineers, industry professionals, and enthusiasts alike.

Definition and Core Structure

At its essence, a butterfly valve is a quarter-turn flow control device designed to regulate, start, slow, or stop the movement of media—such as liquids, gases, or slurries—within large-diameter piping systems. Its fundamental components include a circular disc, a central rod (or stem), and an actuator. The disc, typically mounted concentrically or eccentrically within the pipe, serves as the primary flow-control element: rotating 90 degrees around the stem to adjust its position relative to the media flow. When the disc is parallel to the flow, the valve is fully open, allowing unimpeded passage; when perpendicular, it is fully closed, blocking flow. In intermediate positions, it modulates flow rate with precise incremental adjustments.

A defining feature that distinguishes Butterfly Valves from other valve types—such as gate valves, globe valves, or ball valves—is the disc’s permanent presence in the flow path. Unlike ball valves, which enclose the ball in a cavity when open, or gate valves, which lift a gate out of the flow, the butterfly valve’s disc remains immersed in the media regardless of position. This design inherently creates a pressure drop across the valve, a trade-off balanced by its compact size, low weight, and rapid actuation capabilities.

The stem, which traverses the center of the disc, acts as the link between the disc and the external actuator. Actuators—whether manual (handwheels, levers), pneumatic, hydraulic, or electric—convert input energy into rotational motion, driving the disc’s 90-degree movement. This simplicity of design not only reduces manufacturing costs but also minimizes maintenance needs, making butterfly valves a preferred choice for large-scale systems where operational efficiency is critical.

Etymology: Why “Butterfly” Valve?

The nomenclature of industrial valves often reflects their form or function: ball valves derive their name from the spherical closure element, gate valves from the gate-like barrier they deploy, and needle valves from their slender, needle-shaped plugs. The butterfly valve, however, owes its name to the graceful, wing-like motion of its disc.

The analogy is striking: the central stem resembles a butterfly’s body, while the disc, rotating up and down through a 90-degree arc, mimics the fluttering movement of a butterfly’s wings as it alights. This motion—fluid, efficient, and constrained to a quarter-turn—captures the valve’s operational essence, making the term both descriptive and memorable. Beyond mere symbolism, this movement is key to the valve’s performance: it enables quick shutoff and modulation, ensuring responsive control in dynamic systems.

Operational Principles

Butterfly valves belong to the family of quarter-turn valves, a category defined by the 90-degree rotation required to transition from fully open to fully closed. This design aligns them with ball valves in terms of actuation speed, but with a critical distinction: butterfly valves offer incremental flow control, whereas traditional ball valves are primarily used for on/off service. This versatility stems from the disc’s ability to assume any position between 0 (open) and 90 degrees (closed), allowing for precise modulation of flow rate.

The operational cycle begins with the actuator initiating rotation of the stem. As the stem turns, the disc pivots: in the open position, it lies parallel to the media flow, presenting minimal resistance and allowing maximum throughput. As it rotates toward the closed position, the disc increasingly obstructs the pipe bore, reducing flow until it forms a complete seal when perpendicular to the flow. The pressure drop inherent in this design is a function of the disc’s surface area and the media’s velocity, a factor engineers must account for when sizing valves for specific systems.

Sealing is a critical aspect of butterfly valve operation, varying by design type. In resilient-seated valves, a rubber or elastomeric seal around the disc or valve body creates a tight closure when the disc is fully closed. In metal-seated designs, precision machining ensures metal-to-metal contact, enabling high-temperature and high-pressure performance. The seal’s integrity directly impacts the valve’s ability to prevent leakage, a parameter of utmost importance in applications such as petroleum processing or chemical handling, where even minor leaks pose safety or environmental risks.

Design Variations: Tailoring to Application Needs

Butterfly valves are not a one-size-fits-all solution; their design has evolved into three primary configurations, each optimized for specific operating conditions, pressure ranges, and media types. These variations—zero-offset, double-offset, and triple-offset—differ in the positioning of the stem relative to the disc and pipe bore, a feature that profoundly influences their sealing performance, durability, and application suitability.

Zero-Offset Butterfly Valves

Also known as concentric or rubber-seated valves, zero-offset designs are the most basic and widely used butterfly valves. As the name suggests, the stem is centered (no offset) relative to both the disc and the pipe bore. The sealing mechanism relies on interference between the disc’s edge and a rubber seat, which lines the valve body. When closed, the disc compresses the rubber seat, creating a tight seal that prevents leakage.

Key Characteristics:

- Pressure and Temperature Ratings: Limited to lower pressures (up to 250 PSI) and temperatures (up to 400°F), due to the rubber seat’s material constraints.

- Media Compatibility: Ideal for non-abrasive, non-corrosive media such as water, wastewater, and some food-grade liquids. The rubber seat isolates the media from the valve body, preserving media purity—a critical feature in applications like potable water systems or food processing.

- Cost and Maintenance: Economical to manufacture and install, with minimal maintenance requirements. The rubber seat is replaceable, extending the valve’s service life.

Zero-offset valves excel in low-stakes, high-volume applications where cost and simplicity are prioritized over extreme performance.

High-Performance

Butterfly Valves

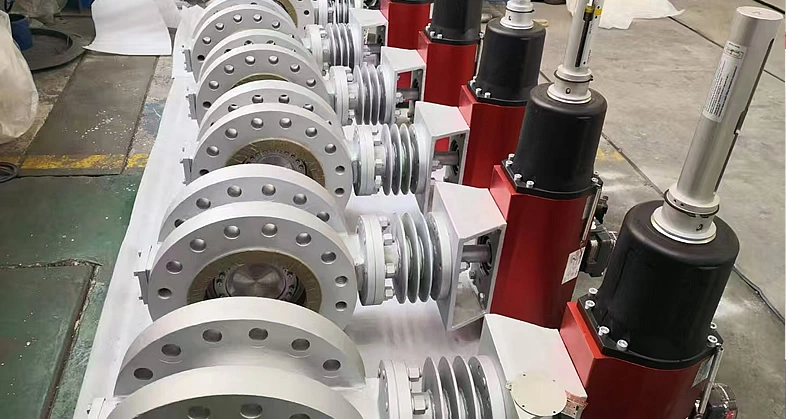

Double-offset Butterfly valves represent a significant advancement in butterfly valve technology, designed to address the limitations of zero-offset models in higher-pressure and higher-temperature environments. The “double offset” refers to two deliberate shifts in the stem’s position: first, offset from the pipe bore’s centerline, and second, offset from the disc’s sealing surface. This design creates a cam-like action as the disc rotates, reducing friction between the disc and seat during actuation.

Key Characteristics:

- Sealing Mechanism: The cam action ensures the disc only contacts the seat during the final 10 degrees of closing (and initial 10 degrees of opening), minimizing wear and extending seal life. Seats may be made of reinforced elastomers or metals, depending on application needs.

- Pressure and Temperature Ratings: Capable of handling pressures up to 1440 PSI and temperatures up to 1200°F, making them suitable for industrial processes involving steam, hydrocarbons, and moderate corrosives.

- Durability: Reduced friction and robust construction (often with steel bodies) enhance durability, making them a staple in refineries, chemical plants, and power generation facilities.

The double-offset design balances performance and cost, offering a “high-performance” alternative to zero-offset valves without the complexity of triple-offset models.

Triple-Offset Butterfly Valves

Triple-offset butterfly valves represent the pinnacle of butterfly valve engineering, engineered for extreme conditions where tight sealing, high pressure, and high temperature resistance are non-negotiable. Building on the double-offset design, they add a third offset: the sealing surface of the disc is machined into a right-angled conical profile, while the seat features a complementary beveled edge. This metal-to-metal sealing mechanism eliminates friction entirely until the final moments of closure.

Key Characteristics:

- Sealing Performance: Achieves “bubble-tight” shutoff—meaning no measurable leakage—even under high pressure, due to the precision-machined metal seal. This makes them ideal for critical applications such as natural gas pipelines, petrochemical processing, and high-pressure steam systems.

- Pressure and Temperature Ratings: The most robust of the three types, withstanding pressures up to 1480 PSI and temperatures up to 1200°F. The metal seal (often made of stainless steel or nickel alloys) resists corrosion and degradation in harsh environments.

- Emissions Control: Designed to minimize fugitive emissions, aligning with strict environmental regulations in industries like oil and gas.

Triple-offset valves are the go-to choice for high-stakes applications where reliability, safety, and compliance are paramount, despite their higher initial cost.

Installation Considerations

Proper installation is critical to maximizing a butterfly valve’s performance, longevity, and safety. Unlike some valves, butterfly valves are sensitive to their positioning relative to other piping components, flow dynamics, and operational stresses.

Piping Layout and Clearances

Butterfly valves require a straight run of pipe upstream and downstream to ensure uniform flow distribution, which optimizes control accuracy and minimizes wear. A general guideline is to maintain a distance of at least six pipe diameters from pumps, elbows, tees, or other valves. This reduces turbulence, which can cause uneven pressure on the disc and premature seal degradation.

When installed near pumps or check valves, additional clearance is necessary to prevent interference between the disc and adjacent components. The valve’s stem orientation is also a key consideration: while vertical stem mounting (with the actuator above the valve) is standard for ease of access and operation, horizontal mounting may be required in tight spaces, provided it does not compromise actuation or maintenance.

Alignment and Torque

Misalignment between the valve and piping can cause uneven loading on the disc and stem, leading to binding, leaks, or actuator failure. Proper alignment ensures the disc rotates freely through its 90-degree arc. Additionally, actuators must be sized to deliver the correct torque: insufficient torque may result in incomplete closure (and leakage), while excessive torque can damage the seat or stem. Manufacturers typically provide torque specifications based on valve size, pressure, and media type.

Material Compatibility

The valve body, disc, seat, and stem materials must be compatible with the media to prevent corrosion, erosion, or chemical reactions. For example:

- In food processing, 304 or 316 stainless steel bodies and food-grade elastomer seats (e.g., EPDM) are standard to meet sanitary requirements.

- In saltwater environments (e.g., shipbuilding), bronze or nickel-aluminum-bronze components resist corrosion.

- In high-temperature applications (e.g., power plants), Inconel or Hastelloy alloys may be used for stems and discs.

Common Applications

Butterfly valves’ adaptability—coupled with their compact design, low cost, and varied performance capabilities—makes them indispensable across a range of industries. Below are key sectors where their unique attributes solve critical operational challenges.

Food Processing

In food and beverage production, hygiene, media purity, and ease of cleaning are paramount. Butterfly valves excel here due to their simple, crevice-free design, which minimizes bacterial growth. Food-grade models feature:

- Sanitary Seats: White-colored, 3A-approved elastomeric seats (e.g., silicone or EPDM) that meet FDA standards for contact with consumables.

- Material Options: Valve bodies constructed from epoxy-coated iron, nylon 11-coated iron, bronze, or 304/316 stainless steel—materials chosen for corrosion resistance and ease of sanitization.

- Low Maintenance: The absence of complex internal components simplifies disassembly and cleaning, reducing downtime during routine sanitation cycles.

From regulating the flow of dairy products to controlling syrup in beverage lines, butterfly valves ensure compliance with strict food safety protocols while maintaining efficient operation.

Refineries and Petrochemical Plants

Refineries and petrochemical facilities demand valves that can withstand extreme pressures, high temperatures, and corrosive or flammable media. Here, high-performance double-offset and triple-offset butterfly valves are preferred for their:

- Fire Safety: Many models are “fire-safe” certified, meaning they maintain sealing integrity even during a fire, preventing the release of hazardous materials.

- Bubble-Tight Shutoff: Critical for isolating sections of the pipeline during maintenance or emergencies, preventing leaks of volatile hydrocarbons.

- Durability: Steel bodies and metal seats resist erosion from abrasive media like crude oil or slurry, ensuring long service life in harsh conditions.

Resilient-seated zero-offset valves also find use in water handling systems within refineries, where their low cost and reliable performance are sufficient for non-critical applications.

General Shut-Off Service

Butterfly valves are widely adopted as general shut-off valves in piping systems with diameters ranging from 1.5 inches to 148 inches. Their advantages over gate or globe valves in this role include:

- Compact Design: They occupy significantly less space than gate valves, which require linear actuation, making them ideal for tight installations.

- Lightweight Construction: Easier to handle and install, reducing labor costs and structural loads on piping.

- Tighter Sealing: Compared to gate valves, which often suffer from leakage due to seat wear, butterfly valves—especially double- and triple-offset models—provide consistent, bubble-tight shutoff.

From municipal water systems to industrial process lines, they serve as reliable isolation devices, ensuring safe and efficient system shutdowns.

Shipbuilding and Marine Applications

Ships and offshore structures operate in highly corrosive saltwater environments, with limited space and strict safety requirements. Butterfly valves are well-suited to these conditions due to:

- Corrosion Resistance: Use of ABS-approved materials (e.g., bronze, duplex stainless steel) that withstand saltwater exposure.

- Compact Size: Their low profile fits into the tight spaces common aboard ships, such as ballast systems, bilge lines, and seawater intake pipes.

- Versatile Actuation: Compatibility with pneumatic, electric, or hydraulic actuators, including “closed-loop” pneumatic systems for underwater applications.

- Standardization: Valves with ISO 5211 mounting pads and stems ensure easy replacement at ports worldwide, minimizing downtime for repairs.

Fire-safe certified models are also critical aboard ships, where fire risks demand valves that maintain integrity during emergencies.

The butterfly valve’s evolution from a simple flow control device to a sophisticated, application-specific solution underscores its enduring relevance in modern industry. Its ability to balance cost, performance, and versatility—whether in low-pressure water systems or high-stakes petrochemical plants—makes it a cornerstone of fluid control engineering.By understanding the nuances of its design variations, operational principles, and installation requirements, engineers and industry professionals can select the optimal butterfly valve for their needs, ensuring efficiency, safety, and reliability. As industrial processes continue to advance, the butterfly valve will undoubtedly adapt, remaining a vital tool in the pursuit of precision and performance.