Low Temperature SS304/316L Forged Steel Extended Stem Socket Weld/Butt Weld Electric Cryogenic Ball Valve

I. Key Attributes and Specification Parameters

TIANYU’s low-temperature electric cryogenic ball valve is engineered to meet the rigorous demands of industrial low-temperature fluid control, with specifications tailored to ensure compatibility across diverse operating conditions.

In terms of pressure handling, the valve accommodates multiple nominal pressure ratings, including PN10, PN16, 150LB, 300LB, and JIS10K, making it suitable for both low and high-pressure systems. Stringent pressure testing validates its structural integrity: shell tests apply 1.5 times the nominal pressure (e.g., 2.4MPa for PN16) with a 30-minute hold to check for deformation or leakage. Seal tests use 1.1 times the nominal pressure for liquid media (1.76MPa at PN16) and 0.3–0.8MPa for gas, ensuring zero leakage through precision pressure drop monitoring.

Temperature resistance is a defining feature, with the valve operating reliably across a range of -196℃ to +80℃. This breadth allows it to handle ultra-cold media such as liquid nitrogen (-196℃), liquid oxygen (-183℃), and liquid argon (-185.9℃), while also accommodating ambient and moderately high-temperature fluids like hot water and steam. The design prevents material embrittlement and seal degradation even under extreme thermal fluctuations.

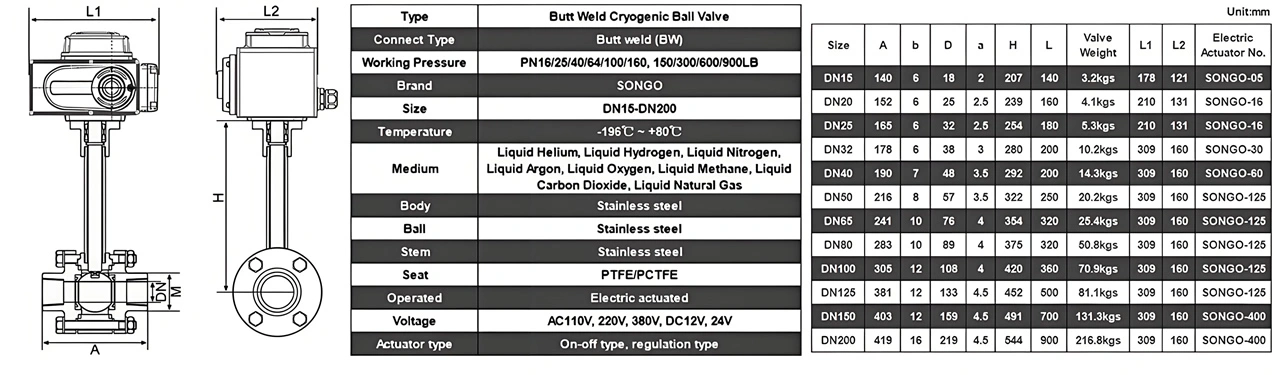

Size and connection options cater to varied pipeline requirements, with nominal diameters from DN15 (1/4 inch) to DN200. Socket weld (SW) and butt weld (BW) connections are available: SW conforms to ASME B16.11, ideal for small to medium-diameter lines requiring compact, leak-tight joints; BW adheres to GB/T 14383, suited for large-diameter or high-pressure systems where weld strength is critical. Both connections eliminate the need for additional adapters, simplifying installation.

Material selection prioritizes durability and corrosion resistance. The valve body, ball, and stem are crafted from SS304 or SS316L forged stainless steel. SS304 offers excellent general corrosion resistance and low-temperature toughness, while SS316L, enhanced with molybdenum, provides superior resistance to acids, alkalis, and marine environments. For seals, PTFE or PCTFE is used—both maintain elasticity at -196℃, resist chemical attack, and ensure long-term sealing performance.

The electric actuator is designed for versatility and precision. It accepts voltages including 12V DC, 24V DC, 110V AC, 220V AC, and 380V AC, adapting to global power standards. Control signals such as 4–20mA DC, 1–5V DC, 0–10V DC, and RS485 enable seamless integration with PLC and DCS systems for remote operation. Actuator response times (90° cycle) range from 15S to 100S, with fast-acting models for emergency shutdowns and slower variants for steady regulation. Protection ratings (IP65/IP67/IP68) shield internal components from dust, water, and submersion. Actuators are available in on-off (for binary control) and modulating (±1% accuracy) configurations to match process needs.

Additional features include broad media compatibility (water, steam, gases, cryogens, corrosives), a 12-month warranty, and compliance with ISO 5211 for actuator mounting, enhancing interchangeability and maintenance efficiency.