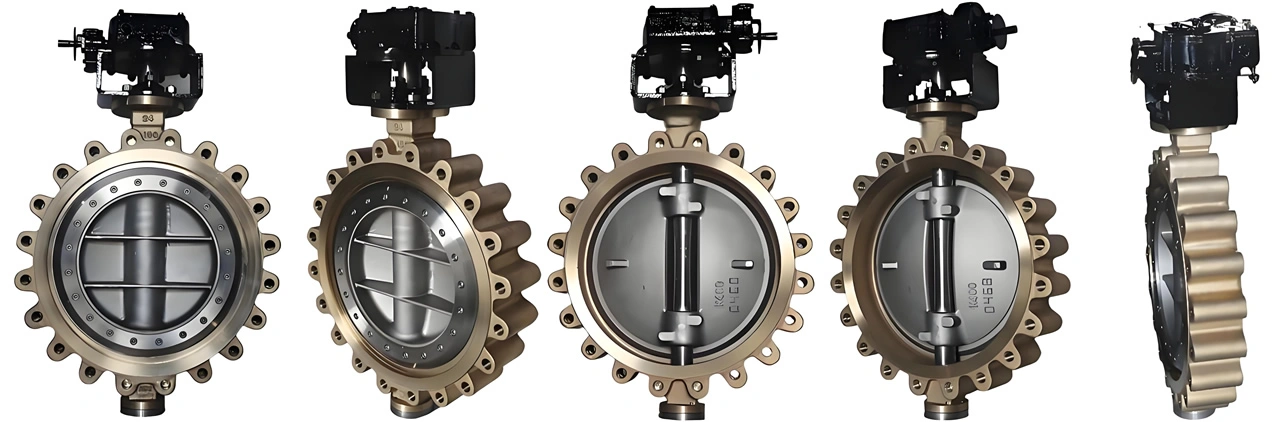

The valve incorporates a triple offset design, where the disc axis is offset from the valve body axis (first offset), the disc sealing surface is offset from the disc axis (second offset), and the sealing cone angle is offset from the pipeline axis (third offset). This configuration eliminates metal-to-metal contact between the disc and seat during rotation, reducing friction and wear. As the valve closes, the disc rotates into a precise, linear contact with the multi-level seal, ensuring uniform pressure distribution across the sealing surface—critical for achieving zero leakage in high-pressure applications (e.g., industrial steam lines). Unlike concentric or double offset designs, triple offset minimizes seal deformation, extending service life in cyclic operations.

Constructed from ASTM B148 C95800 aluminum bronze, the valve body and lugs excel in corrosive environments, particularly saline or wet conditions. The alloy’s aluminum content forms a protective oxide layer, resisting pitting and crevice corrosion from seawater, chlorinated water (municipal treatment), and mild acids. In marine applications (e.g., ballast systems or seawater intake), this eliminates the need for external coatings, reducing maintenance costs. Compared to carbon steel or cast iron, aluminum bronze also offers high strength-to-weight ratio, ensuring structural integrity in large-diameter (DN600+) valves without excessive weight.

The multi-level hard seal features a series of alloy-coated metal ridges, creating a labyrinth effect that blocks media flow at multiple points. This design enhances sealing reliability by distributing pressure across the seal, preventing leakage even if one level is compromised. The alloy coating (e.g., stellite) resists high temperatures (up to 425°C) and abrasion from particulate media (e.g., sewage solids, mining slurries). Unlike soft seals (PTFE), hard seals avoid degradation in high-temperature or aggressive chemical environments, making the valve suitable for industrial processes involving steam, hydrocarbons, or acidic fluids.

Lug-type design integrates threaded bolt holes in the valve lugs, aligning with pipeline flanges for secure mounting. This allows the valve to be installed between flanges without requiring full pipeline disassembly, simplifying retrofits in existing systems. The design also enables unilateral maintenance: if one flange side is inaccessible (e.g., buried pipelines), the valve can be removed from the accessible side, reducing downtime in critical infrastructure (e.g., municipal water mains).

Manual gear operation reduces torque requirements by leveraging gear reduction, enabling one-person operation of large-diameter valves (e.g., DN600). The gear housing is sealed to protect internal components from debris, moisture, and corrosion, ensuring smooth operation in outdoor or dirty environments (e.g., construction sites, mining facilities). For automated systems, optional pneumatic or electric actuators integrate with PLC/DCS controls, enabling remote operation and real-time flow monitoring—ideal for industrial processes requiring precise flow modulation.

The valve disc is crafted from K400 (austenitic manganese steel), a material renowned for work hardening: as abrasive particles (e.g., sand, slurry solids) impact the surface, the disc hardness increases (HB ≥400), resisting wear over time. In applications like sewage treatment or mining slurry lines, this extends disc life by 2~3 times compared to standard stainless steel, reducing replacement frequency and maintenance costs. The disc’s smooth, precision-machined surface also minimizes pressure drop, optimizing flow efficiency in large-diameter pipelines (e.g., water distribution mains).

- Alloy Verification: Aluminum bronze castings (body, lugs) and K400 discs undergo spectral analysis to confirm chemical composition—ensuring compliance with ASTM B148 (C95800) and K400 standards (e.g., manganese content ≥11%).

- Defect Detection: Ultrasonic testing and dye penetrant inspection identify internal/external defects (e.g., porosity, cracks) in cast components, critical for maintaining pressure integrity in high-pressure applications.

- Heat Treatment: K400 discs undergo solution annealing to enhance toughness, ensuring they withstand impact from abrasive media without fracturing.

- CNC Machining: Valve body, disc, and seal surfaces are machined using 5-axis CNC centers to tight tolerances (±0.05mm). This ensures precise alignment of the triple offset geometry, critical for reducing friction and achieving uniform sealing.

- Seal Groove Fabrication: Multi-level seal grooves are milled into the valve body, with each ridge machined to exact dimensions (height, width) to create the labyrinth effect.

- Lug & Flange Machining: Lug bolt holes are drilled and tapped per AWWA C504 standards, with chamfered edges to simplify bolt insertion during installation. Flange faces are machined to Ra ≤3.2μm for compatibility with pipeline gaskets.

- Multi-Level Seal Fabrication: Metal seal components are precision-bent and welded to the valve body, ensuring each ridge is concentric with the disc path. The seals then undergo alloy coating (e.g., stellite welding) to enhance hardness and corrosion resistance.

- Coating Cure: Coated seals are heat-treated to bond the alloy to the base metal, preventing flaking in high-temperature or abrasive environments.

- Disc & Stem Assembly: The K400 disc is mounted to the stainless steel stem, with bearings to minimize rotational friction. The stem is sealed with graphite packing to prevent media leakage while maintaining smooth operation.

- Gear Operator Installation: Gear components (pinion, worm) are assembled and lubricated with high-temperature grease, then sealed in a weatherproof housing. Torque testing ensures the gear system reduces operating force by 30~50% as specified.

- Hydrostatic Body Test: The valve body is pressurized to 1.5×rated pressure (e.g., 3.75MPa for Class 150) for 30 minutes, with no visible leakage or deformation.

- Seal Leak Test: Under 1.1×rated pressure (e.g., 2.75MPa for Class 150) using air or nitrogen, the valve must achieve ANSI/FCI Class V leakage (zero measurable leakage).

- Cycle Test: The valve undergoes 10,000+ open-close cycles with abrasive media to verify seal and disc durability, ensuring performance remains consistent over time.

- Torque Verification: Gear-operated valves are tested to confirm operating torque stays within specified limits (e.g., ≤500N·m for DN600), ensuring ease of manual operation.